Super-hydrophobic surface formed on basis of dihydrazide derivative molecular gel

A super-hydrophobic, molecular gel technology, applied in the field of nano-micron surfaces, can solve the problems of inability to promote engineering material surfaces, harsh experimental conditions, practical application limitations, etc., and achieve the effects of low cost, simple chemical substances, and simple experimental conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A method for constructing a superhydrophobic surface based on a diamide derivative molecular gel, comprising the following steps:

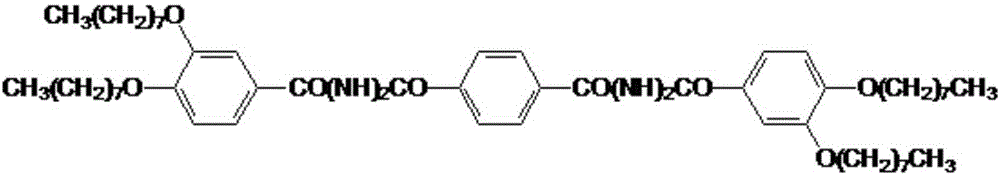

[0025] (1), 3,4-dioctyloxybenzoyl hydrazide and terephthaloyl chloride are dissolved in tetrahydrofuran solution respectively; Then the tetrahydrofuran solution of terephthaloyl chloride is added dropwise to 3, 4-dioctyloxybenzohydrazide solution in tetrahydrofuran; after the dropwise addition is completed, add a small amount of pyridine and react at room temperature for 8 hours to obtain the crude product of BPH-8, freeze and filter the crude product, and use tetrahydrofuran poly Second recrystallization to obtain high-purity BPH-8;

[0026] (2), add BPH-8 in a well-sealed flask, add a mixed solvent of ethanol and DMSO, control the volume ratio of ethanol and DMSO to 10:1, heat to completely dissolve the gel factor, and obtain 0.23 %The solution;

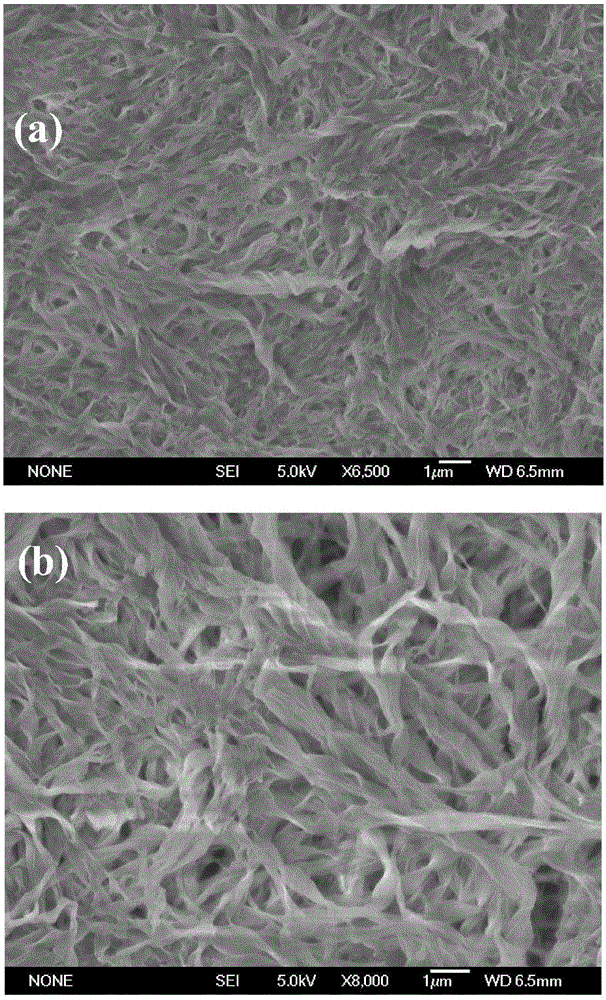

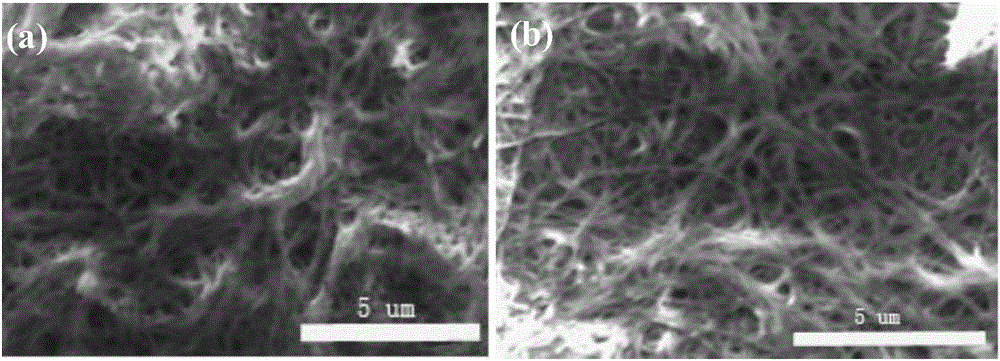

[0027] (3), apply the BPH-8 solution to the substrate while it is hot to form a thin film,...

Embodiment 2

[0031] A method for constructing a superhydrophobic surface based on a diamide derivative molecular gel, comprising the following steps:

[0032] (1), 3,4-dioctyloxybenzoyl hydrazide and terephthaloyl chloride are dissolved in tetrahydrofuran solution respectively; Then the tetrahydrofuran solution of terephthaloyl chloride is added dropwise to 3, 4-dioctyloxybenzohydrazide solution in tetrahydrofuran; after the dropwise addition is completed, add a small amount of pyridine and react at room temperature for 8 hours to obtain the crude product of BPH-8, freeze and filter the crude product, and use tetrahydrofuran poly Second recrystallization to obtain high-purity BPH-8;

[0033] (2) Add BPH-8 to a well-sealed flask, add a mixed solution of THF, DMSO and ethanol, control the volume ratio of THF, DMSO and ethanol to 10:1:2-10, and heat to completely dissolve the gel factor , to obtain a solution containing 0.43% of BPH-8;

[0034] (3), apply the BPH-8 solution to the substrate...

Embodiment 3

[0038] A method for constructing a superhydrophobic surface based on a diamide derivative molecular gel, comprising the following steps:

[0039] (1), 3,4-dioctyloxybenzoyl hydrazide and terephthaloyl chloride are dissolved in tetrahydrofuran solution respectively; Then the tetrahydrofuran solution of terephthaloyl chloride is added dropwise to 3, 4-dioctyloxybenzohydrazide solution in tetrahydrofuran; after the dropwise addition is completed, add a small amount of pyridine and react at room temperature for 8 hours to obtain the crude product of BPH-8, freeze and filter the crude product, and use tetrahydrofuran poly Second recrystallization to obtain high-purity BPH-8;

[0040] (2), add BPH-8 in a well-sealed flask, add a mixed solution of THF and ethanol, control the volume ratio of THF and ethanol to be 1:2, heat to completely dissolve the gel factor, and obtain BPH-8 containing 0.35% solution;

[0041] (3), apply the BPH-8 solution to the substrate while it is hot to for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com