Method for preparing hydration silicon dioxide with blast furnace water-quenched slag

A technology of hydrated silica and blast furnace water quenching slag, which is applied in the direction of silica, silicon oxide, chemical instruments and methods, etc., to achieve low process cost, obvious environmental and social benefits, and the effect of eliminating pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

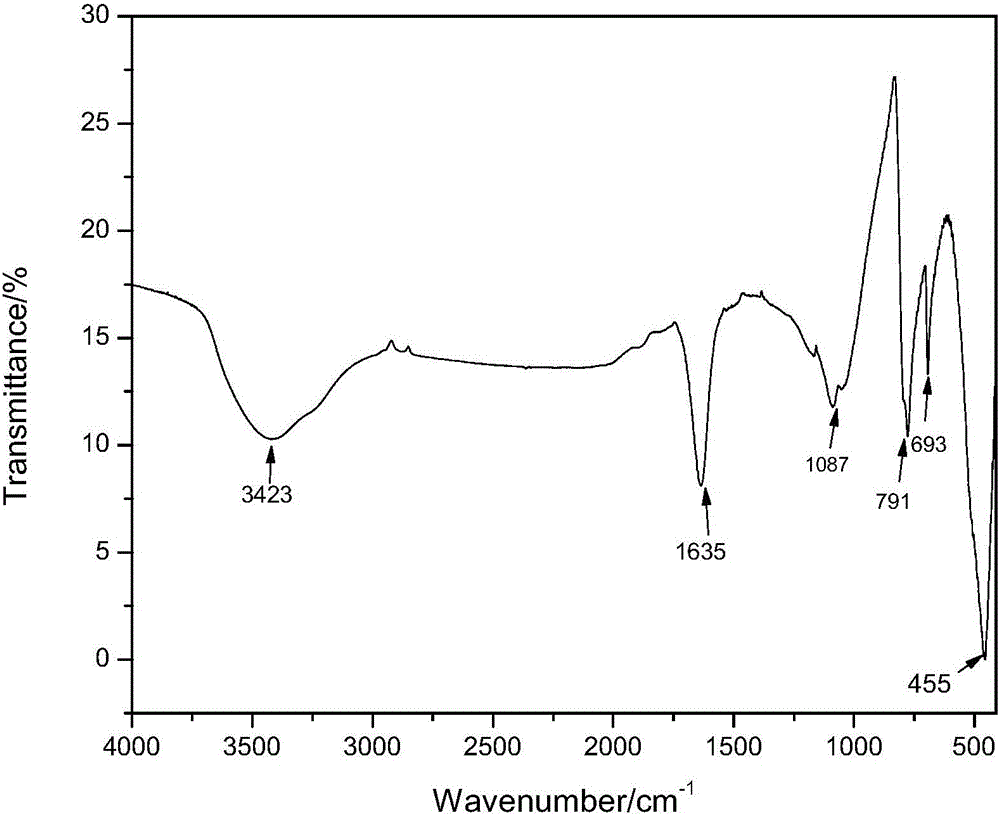

Image

Examples

Embodiment 1

[0026] The water-quenched blast furnace slag is dried, crushed and ground, and passed through a 200-mesh sieve. Take the undersize, weigh 15.013g and place it in a high-pressure reactor; weigh 8.881g of caustic soda reagent, add 80ml of deionized water to prepare a solution, add the caustic soda solution into the high-pressure reactor and stir, and then heat the furnace at 150°C Medium hydrothermal reaction 4h. After solid-liquid separation, the resulting filtrate contains Na + , Al 3+ silicate solution. The filtrate was placed in a constant temperature magnetic stirrer, heated to 60°C, and hydrochloric acid solution was slowly added dropwise to adjust the pH value of the silicate solution to 8 to obtain a suspension. Aging the suspension, cooling to normal temperature and filtering, the obtained filter cake was washed with water and pickled, then dried in a blast drying oven to obtain crude hydrated silica; finally, the crude hydrated Silica and water are mixed and stirre...

Embodiment 2

[0028] The water-quenched blast furnace slag is dried, crushed and ground, and passed through a 200-mesh sieve. Take the undersize, weigh 14.624g and place it in a high-pressure reactor; weigh 12.465g of caustic soda reagent, add 80ml of deionized water to prepare a solution, add the caustic soda solution into the high-pressure reactor and stir, and then heat the furnace at 150°C Medium hydrothermal reaction 8h. After solid-liquid separation, the resulting filtrate contains Na + , Al 3+ silicate solution. The filtrate was placed in a constant temperature magnetic stirrer, heated to 60°C, and hydrochloric acid solution was slowly added dropwise to adjust the pH value of the silicate solution to 9 to obtain a suspension. Aging the suspension, cooling to normal temperature and filtering, the obtained filter cake was washed with water and pickled, then dried in a blast drying oven to obtain crude hydrated silica; finally, the crude hydrated Silica and water are mixed and stirr...

Embodiment 3

[0030] The water-quenched blast furnace slag is dried, crushed and ground, and passed through a 200-mesh sieve. Take the undersize, weigh 16.364g and put it in a high-pressure reactor; weigh 10.964g of caustic soda reagent, add 80ml of deionized water to prepare a solution, add the caustic soda solution into the high-pressure reactor and stir, and then heat the furnace at 150°C Medium hydrothermal reaction for 6h. After solid-liquid separation, the resulting filtrate contains Na + , Al 3+ silicate solution. The filtrate was placed in a constant temperature magnetic stirrer, heated to 60°C, and hydrochloric acid solution was slowly added dropwise to adjust the pH value of the silicate solution to 9 to obtain a suspension. Aging the suspension, cooling to normal temperature and filtering, the obtained filter cake was washed with water and pickled, then dried in a blast drying oven to obtain crude hydrated silica; finally, the crude hydrated Silica and water are mixed and sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com