Method for resource utilization of sludge compost

A technology of recycling and sludge, applied in the direction of sewage/sludge fertilizer, application, organic fertilizer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

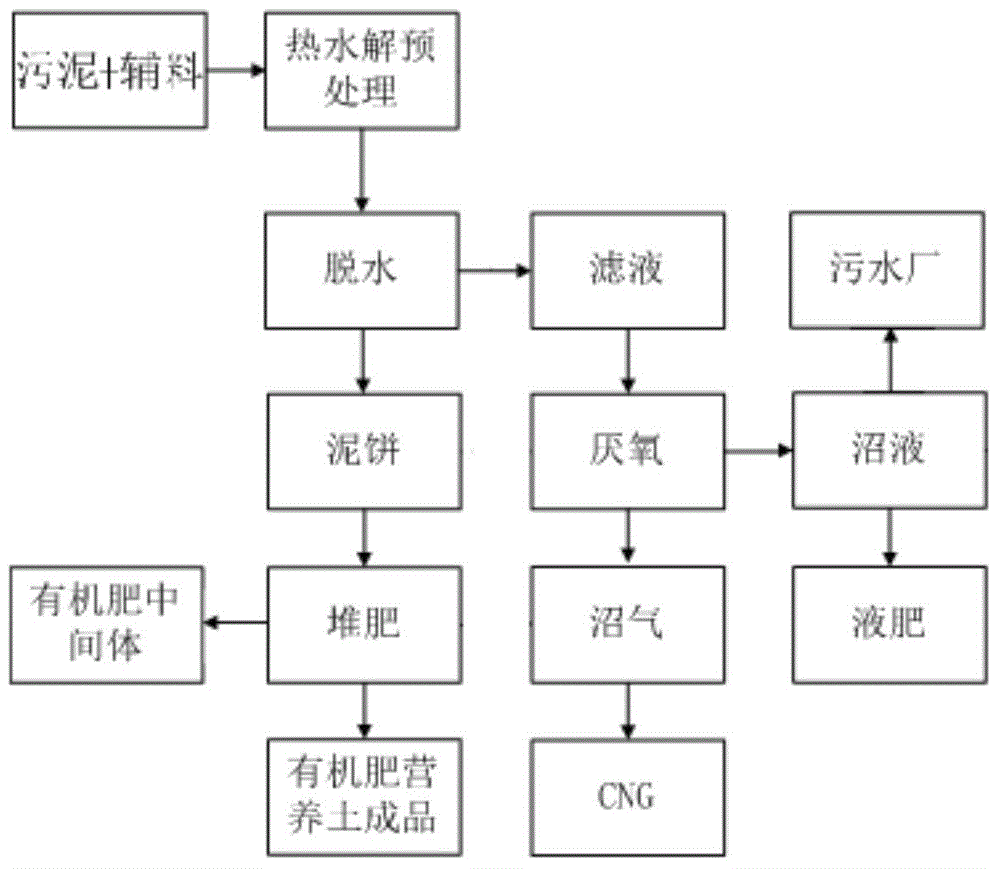

Image

Examples

Embodiment

[0019] The concentrated sludge of an urban sewage treatment plant has a moisture content of 84.1%, a pH value of 7.3, an organic matter of 51%, a bio-based auxiliary material with a moisture content of 38.3%, a pH value of 2.6, an organic matter of 82%, and a blending ratio of 30% (sludge dry basis). The material is subjected to pyrolysis treatment at a high temperature of 190°C, the pressure is 1.2MPa, and the pyrolysis time is 60min. The material after pyrolysis contains 64% of organic matter, the temperature of the material after pyrolysis treatment is cooled to 70°C, and it is directly pumped into the plate and frame filter press (2×800m 2 ) dehydration, feeding time 30min, pressure 0.4MPa, pressing pressure 0.6MPa, production cycle 1.5h, mud cake contains 62% organic matter, about 1.7% total nitrogen, about 2.7% total phosphorus, about 0.5% total potassium, sludge and The organic nutrients of the auxiliary materials enter the filtrate, and the sludge is reduced. The mud ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com