Composite type soil improvement agent and preparation method thereof

A soil conditioner and composite technology, applied in soil conditioning materials, chemical instruments and methods, fertilizer mixtures, etc., can solve the problems of high cost, easy decomposition and dosage of soil conditioners, etc., and achieve low cost, is conducive to waste utilization, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

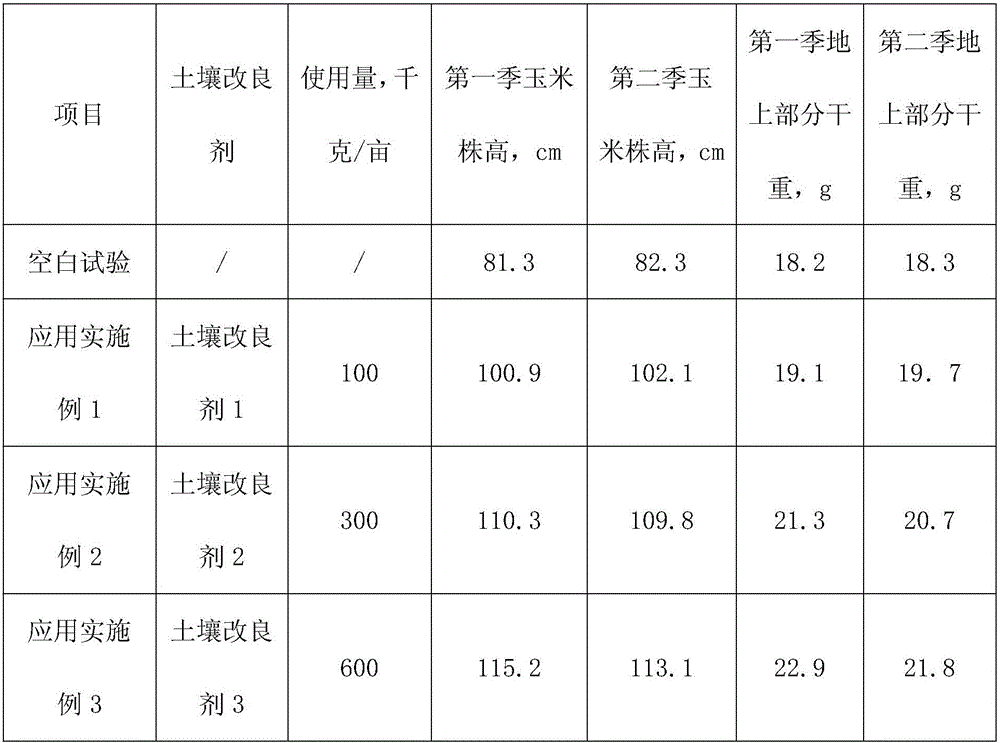

Examples

preparation example Construction

[0023] The invention provides a method for preparing a composite soil conditioner, which is characterized in that the method comprises: a. crushing straw and passing it through a 20-150 mesh sieve to obtain straw powder; b. mixing straw powder obtained in step a with Bentonite, lignin, fly ash, water-soluble polymer compound and water are mixed to obtain a mixed slurry; wherein, the solid content of the slurry is 5-45%, straw powder and bentonite, lignin, fly ash, water-soluble polymer The mass ratio of the compound is 1: (0.03-1): (0.03-1): (0.03-1): (0.03-1); c, the mixed slurry obtained in step b is mixed with a mass ratio of 1: (0.03-0.1) It is mixed with activated carbon with an average particle size of 1-10 microns and then spray-dried to obtain a composite soil conditioner.

[0024] According to the present invention, the straw powder is well known to those skilled in the art, and may be at least one selected from corn straw, sorghum straw, soybean straw and wheat straw...

Embodiment 1

[0035] a, crush corn stalks and pass through a 20-mesh sieve to obtain straw powder; b, mix the straw powder obtained in step a with bentonite, lignin, fly ash, guar gum and water to obtain a mixed slurry; wherein, the slurry The solid content is 5%, and the mass ratio of straw powder to bentonite, lignin, fly ash, and water-soluble macromolecular compound is 1: (0.03-1): 0.5: 0.5: 0.5; c, the mixture obtained in step b The slurry has a mass ratio of 1:0.03 and an average particle size of 5 microns, a pore volume of 1.5ml / g, and a specific surface area of 700m 2 After the gac / g is mixed, carry out spray-drying, the inlet temperature of spray-drying is 400 ℃, and outlet temperature is 250 ℃, then dries at 100 ℃ for 3 hours, obtains composite soil conditioner 1.

Embodiment 2

[0037] a. After pulverizing the wheat straw, pass it through a 70-mesh sieve to obtain straw powder; b. Mix the straw powder obtained in step a with bentonite, lignin, fly ash, starch and water to obtain a mixed slurry; wherein, the solid content of the slurry is The content is 45%, and the mass ratio of straw powder to bentonite, lignin, fly ash, and water-soluble polymer compound is 1:1:1:1:1; c. Mix the slurry obtained in step b with a mass ratio of 1: 0.1 and the average particle size is 1 micron, the pore volume is 1.1ml / g, and the specific surface is 500m 2 After the active carbon of / g is mixed, carry out spray-drying, the inlet temperature of spray-drying is 450 ℃, and outlet temperature is 300 ℃, then dries at 150 ℃ for 6 hours, obtains composite soil conditioner 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com