Method for extracting copper ions through ultrasonic wave channelization

An ultrasonic and copper extraction technology is applied in the field of ultrasonic pipeline extraction of copper ions, which can solve the problems of large retention of organic phase and water phase, increase production cost, reduce production efficiency and other problems, achieve simple operation, improve safety, and reduce environment. The effect of pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

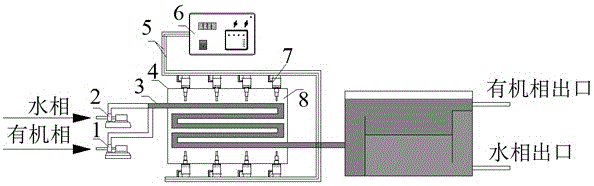

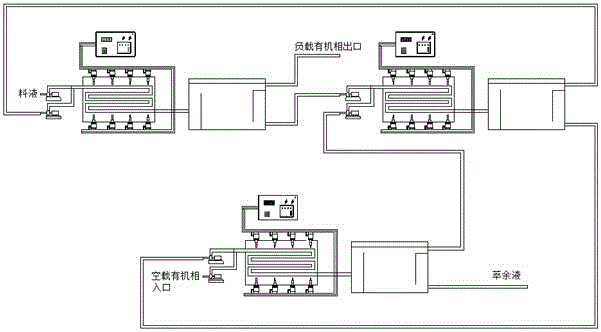

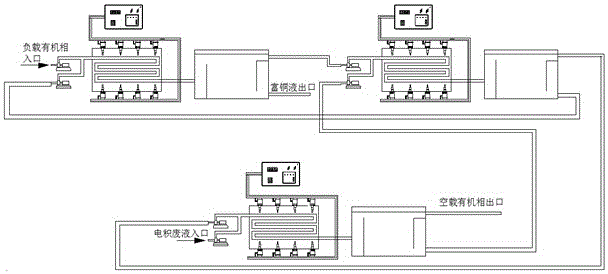

[0023] The method for extracting copper ions by means of ultrasonic pipeline, its specific steps are as follows:

[0024] (1) The feed liquid containing copper ion concentration of 40g / L and the organic phase of the extractant are mixed according to the total flow rate of 100m 3 Pump at a speed of / h into the extraction pipeline reactor extraction pipeline, control the ratio of the organic phase to the water phase to 3:1, the extraction temperature is 80°C, the ultrasonic frequency is 60MHz, the power is 800kW, and the reaction takes 120min to obtain the loaded organic phase. In the extraction process, the extraction pipeline reactors are connected in series to carry out 6-stage countercurrent extraction; wherein the organic phase is 5-dodecyl salicylaldoxime and 2-hydroxyl-5-nonylacetophenone oxime as the extractant (5 in the extractant -The volume ratio of dodecyl salicylaldoxime and 2-hydroxy-5-nonylacetophenone oxime is 1:1) and 260# solvent naphtha as diluent composition ...

Embodiment 2

[0029] The method for extracting copper ions by means of ultrasonic pipeline, its specific steps are as follows:

[0030] (1) The feed liquid containing copper ion concentration of 0.8g / L and the organic phase of the extractant are mixed according to the total flow rate of 0.1m 3 Pump at a speed of / h into the extraction pipeline reactor extraction pipeline, control the ratio of the organic phase to the water phase to be 1:3, the extraction temperature is 20°C, the ultrasonic frequency is 40MHz, the power is 800kW, and the reaction is 0.1min to obtain the loaded organic phase , during the extraction process, the extraction pipeline reactors are connected in series for two-stage countercurrent extraction; wherein the organic phase is 5-dodecyl salicylaldoxime and 2-hydroxyl-5-nonylacetophenone oxime as the extraction agent (in the extraction agent The volume ratio of 5-dodecyl salicylaldoxime to 2-hydroxy-5-nonylacetophenone oxime is 1:1) and 260# solvent naphtha as a diluent (...

Embodiment 3

[0035] The method for extracting copper ions by means of ultrasonic pipeline, its specific steps are as follows:

[0036] (1) The feed liquid containing copper ion concentration of 3g / L and the organic phase of the extractant are mixed according to the total flow rate of 0.4m 3 Pump at a speed of / h into the extraction pipeline reactor extraction pipeline, control the ratio of the organic phase to the water phase to be 1:1, the extraction temperature is 40°C, the ultrasonic frequency is 30MHz, the power is 200kW, and the reaction is 10min to obtain the loaded organic phase. During the extraction process, the extraction pipeline reactors are connected in series for 3 stages of countercurrent extraction; wherein the organic phase is 5-dodecyl salicylaldoxime and 2-hydroxyl-5-nonylacetophenone oxime as the extractant (5 in the extractant -The volume ratio of dodecyl salicylaldoxime and 2-hydroxyl-5-nonylacetophenone oxime is 1:1) and 260# solvent naphtha as diluent composition oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com