Method for improving Shanghai clay through polyvinyl alcohol fibers

A technology of polyvinyl alcohol fiber and clay, which is applied in the field of architecture, can solve the problems that cannot meet the strength and deformation requirements of construction projects, and achieve the effects of improving engineering hidden dangers, enhancing engineering characteristics, and increasing shear strength and compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

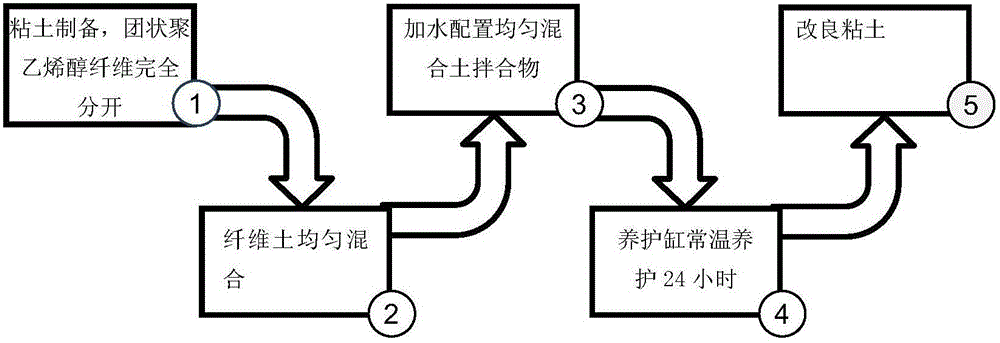

Method used

Image

Examples

Embodiment 1

[0022] First, clay preparation S1 is performed. The clay was taken from the construction site of a large-scale foundation pit project in Shanghai. (This kind of clay has high water content, large void ratio, high compressibility and other properties, which lead to a decrease in the strength of the soil) Its optimum water content is 20.78%, and the maximum dry density is 1.63g / cm 3 , the liquid limit moisture content is 42.27%, and the plastic limit moisture content rate is 20.46%. Air-dried under natural conditions, crushed and sieved. Make the clay particles no larger than 2mm. Take 3000g of soil in a compact state for each group of tests, and divide the soil into three parts.

[0023] Then, the preparation S2 of polyvinyl alcohol fiber is performed. Disperse the fiber group completely, according to the quality of the existing clay, take polyvinyl alcohol fibers according to the mass ratio of fiber to soil at 0.2%, 0.4%, 0.6%, 0.8%, 1.0%, and 1.2% in a dense state, respect...

Embodiment 2

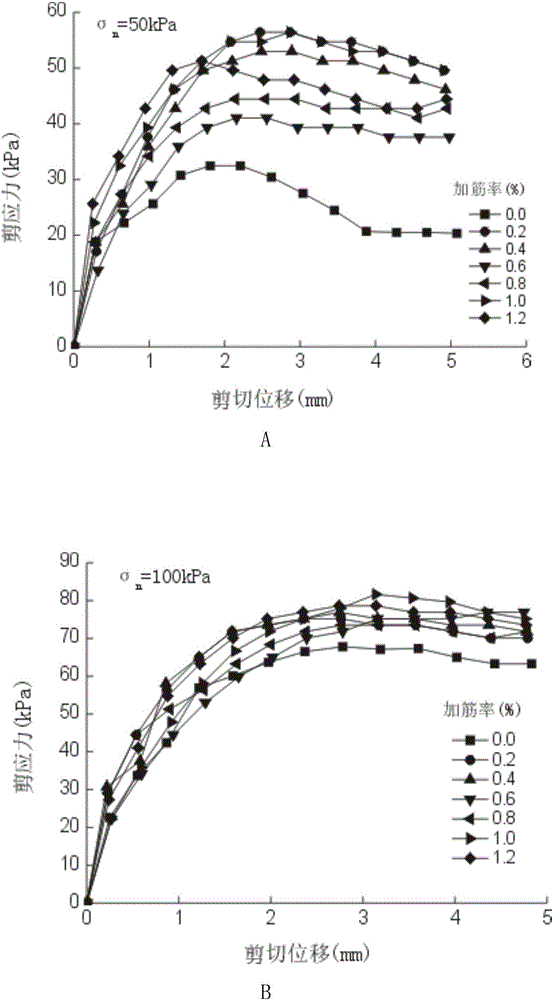

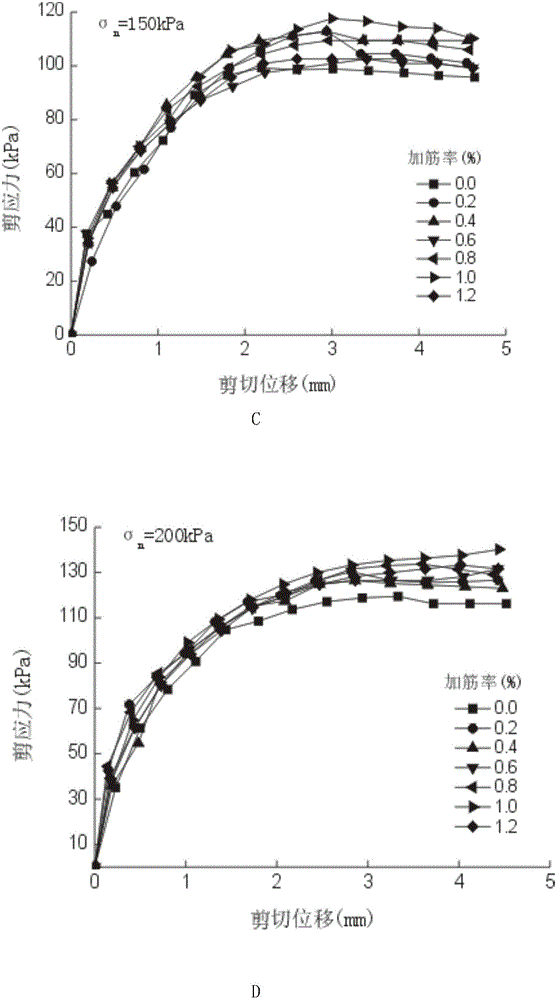

[0028] Example 2 In order to measure the effect of polyvinyl alcohol fibers improving clay, the following comparisons between the test group and the control group were carried out.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dry density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com