Monolithic integration depolarized fiber optic gyroscope optical chip

A fiber optic gyroscope and optical chip technology, applied in the field of integrated optics and inertial sensing, can solve the problems of poor reliability of the coupling point fusion point, small half-wave voltage, large modulation bandwidth, etc., and achieve simple structure, low-loss butt coupling, waveguide simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing.

[0028] In this example, the chip substrate 1 material is Si, and the chip lower cladding layer 2 material is SiO 2 , the waveguide core layer 3 material is Si;

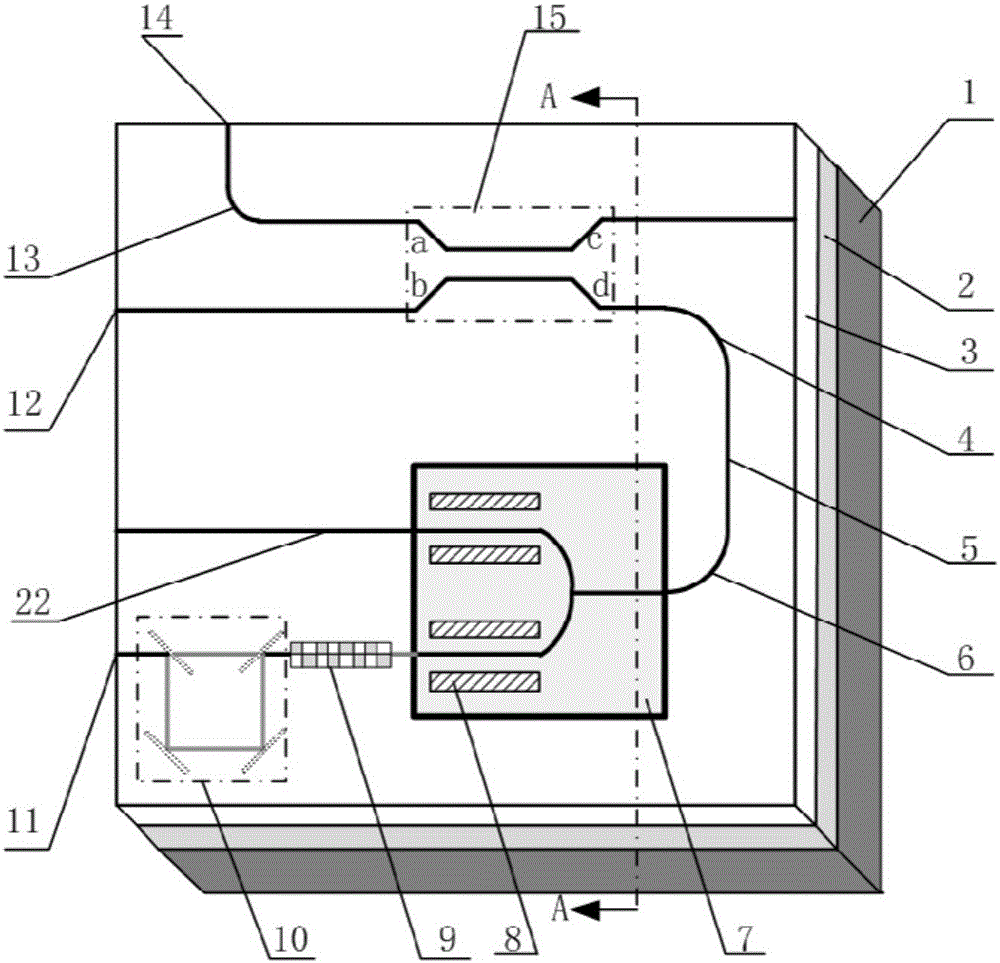

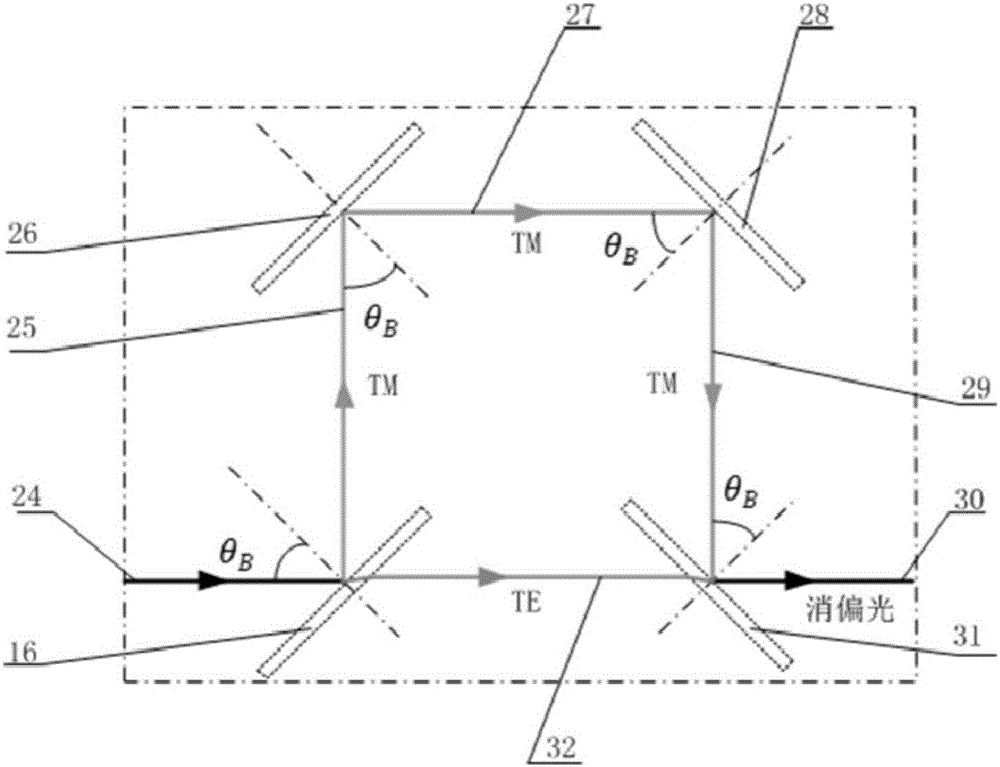

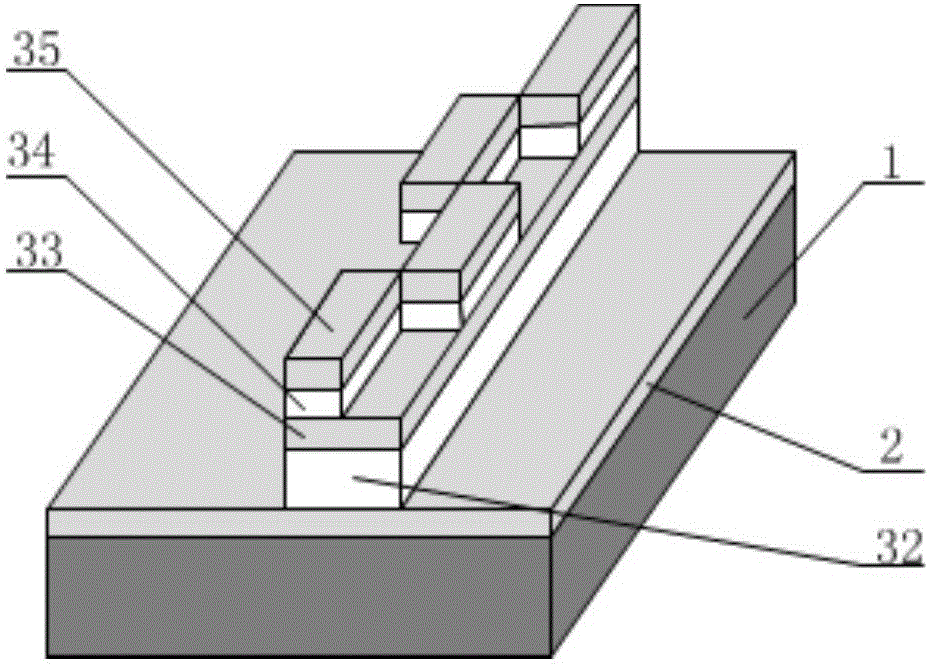

[0029] Such as figure 1 As shown, the waveguide core layer 3 integrates a directional coupler 15, a Y-waveguide modulator 7, a waveguide-type polarization converter 9, and a waveguide-type depolarizer 10, wherein the material of the Y-waveguide modulator 7 is thin-film lithium niobate 21, such as Figure 4 As shown, the light-passing area 23 of the waveguide modulator 7 is a thin-film lithium niobate proton exchange waveguide, and the core layer materials of other devices are all Si waveguides, and the shape of the waveguide is a Si ridge waveguide.

[0030] Port a of the directional coupler 15 is connected to one end of the first 90° arc waveguide 13 through the first straight waveguide, the other end of the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com