A supercritical carbon dioxide phase balance instrument and its application method

A carbon dioxide, phase balance technology, applied in instruments, scientific instruments, measuring devices, etc., can solve the problems of large viewing window area, difficult to guarantee sealing, time-consuming and labor-intensive experiments, etc., to improve experimental test efficiency, reduce experimental errors, The effect of reducing the cost of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

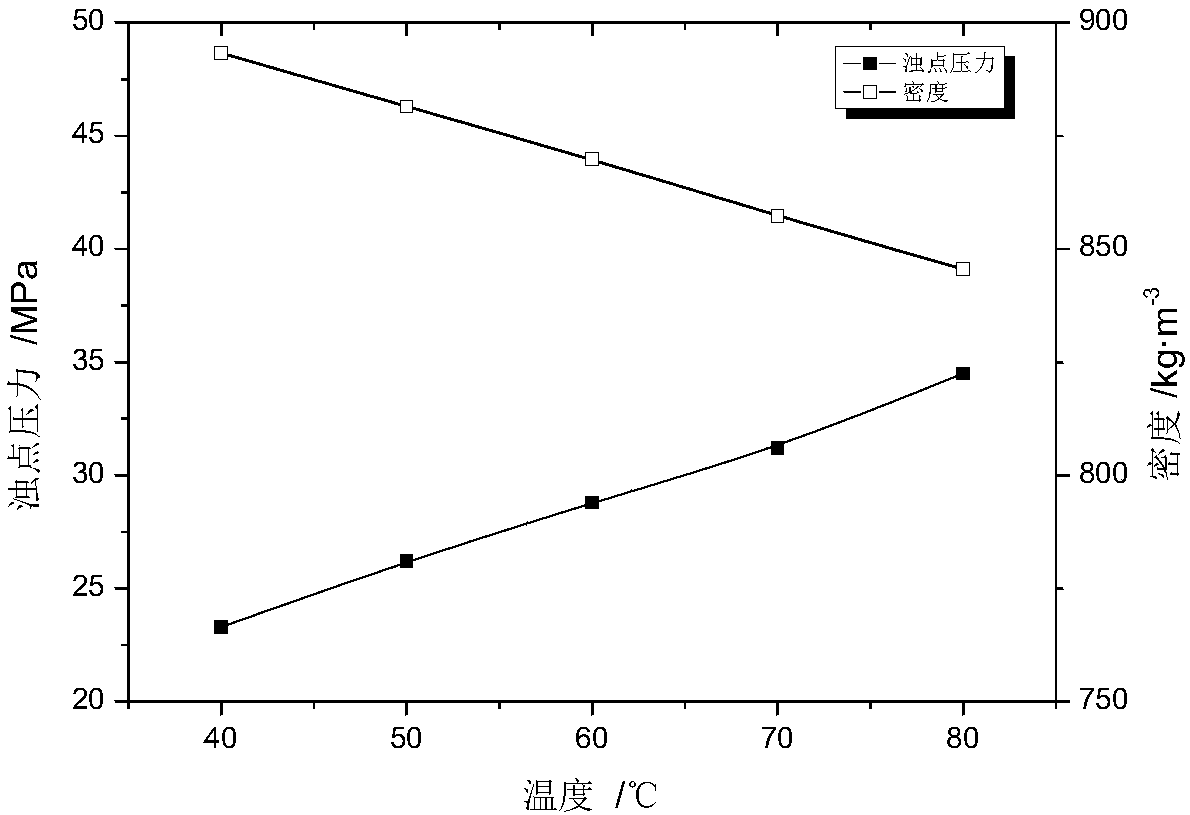

[0069]Add 1 g of polymethyl methacrylate in the phase balance measuring device 1, fill up the upper part of the second intermediate container 6 piston with acetic acid, transfer the carbon dioxide in the storage tank 4 to the phase balance measuring device 1, and use the formula ① to obtain the added The mass of carbon dioxide is 100g, and the acetic acid in the second intermediate container 6 is added to the phase balance measuring device 1, and the mass of the added acetic acid is obtained as 5 g by formula ②. Measure the phase behavior of the medium in the phase balance measuring device 1, use the formula 3. to obtain the density of the system under the cloud point pressure, and draw the supercritical carbon dioxide-acetic acid-polymethyl methacrylate system (three kinds of material mass ratio 100:5: 1) The cloud point pressure and density change curve with temperature, such as image 3 shown.

Embodiment 2

[0071] Keep the experimental condition of embodiment 1, repeat step (8), continue to join the acetic acid in the second intermediate container 6 in the phase balance measuring device 1, utilize formula 2. the quality that obtains the acetic acid that adds for the second time is 5g (in the system The total mass of acetic acid is 10g). Repeat step (9), measure the phase behavior of the medium in the phase balance measuring device 1, utilize formula 3. to obtain the density of the system at the cloud point pressure, draw the supercritical carbon dioxide-acetic acid-polymethyl methacrylate system (three substances Mass ratio 100:10:1) cloud point pressure and density change curve with temperature, such as Figure 4 shown.

Embodiment 3

[0073] Keep the experimental condition of embodiment 2, repeat step (7), continue to add the carbon dioxide in the storage tank 4 in the phase balance measuring device 1, utilize formula 1. to obtain the quality of the carbon dioxide that adds for the second time to be 50g (the total amount of carbon dioxide in the system Mass is 150g). Repeat step (9), measure the phase behavior of the medium in the phase balance measuring device 1, utilize formula 3. to obtain the density of the system at the cloud point pressure, draw the supercritical carbon dioxide-acetic acid-polymethyl methacrylate system (three substances Mass ratio 150:10:1) cloud point pressure and density change curve with temperature, such as Figure 5 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com