Method for producing carbon fiber sample for Raman spectrum test

A Raman spectroscopy and carbon fiber technology, which is used in the preparation of carbon fiber samples, and the preparation of carbon fiber cross-sections and/or cross-section samples, can solve the problems of inability to obtain carbon fiber cross-section samples, large experimental errors, and low success rates. The effect of reduced experimental error and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

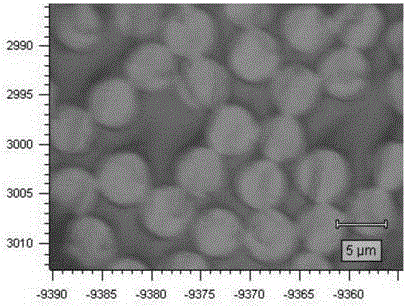

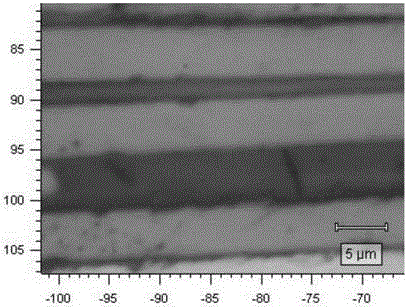

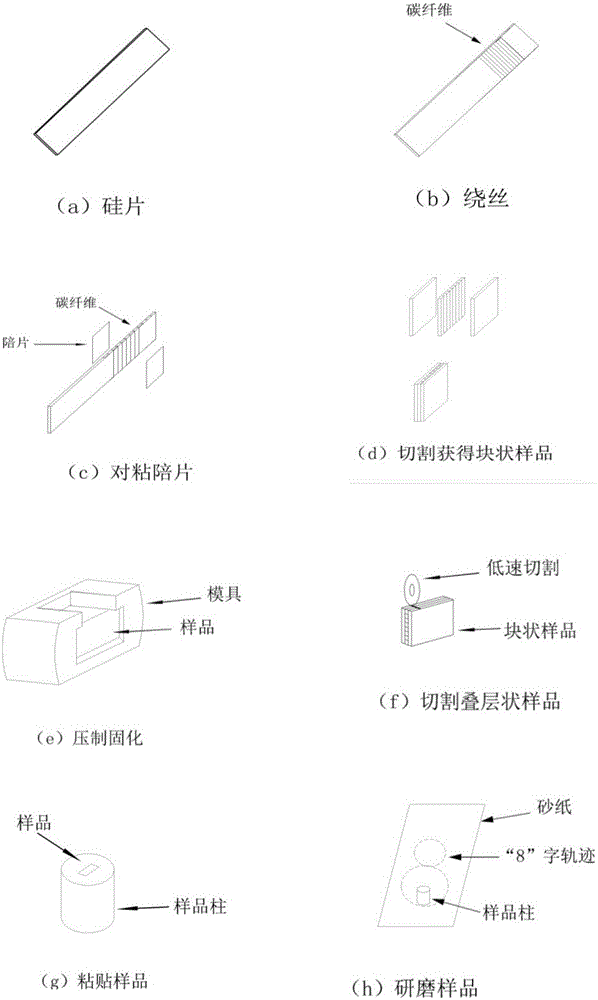

[0039] A preparation method for a carbon fiber sample for Raman spectroscopic testing, comprising the following steps:

[0040] a. Silicon wafer gluing and wire winding: Apply glue on the rectangular parallelepiped silicon wafer, and put a bundle of carbon fiber filaments (the diameter of carbon fiber filaments is any one of 5-8 μm, take 10 carbon fiber monofilaments as a bundle) ( Uniformly and neatly) wound on the position where the glue is coated on the silicon wafer, and wound into a row of carbon fiber filaments with a width of 2mm;

[0041] b. Adhesive companion piece: apply glue on the carbon fiber filaments on the opposite sides of the silicon wafer, and then stick a companion piece on the opposite sides of the area where the carbon fiber filaments are wound, to obtain a sample with the companion piece pasted;

[0042] c. Curing: Put the sample pasted with the accompanying sheet into a mold (preferably a mold made of polytetrafluoroethylene), clamp it with a spring cli...

Embodiment 2

[0046] A preparation method for a carbon fiber sample for Raman spectroscopic testing, comprising the following steps:

[0047] a. Silicon wafer gluing and wire winding: apply glue on the cuboid silicon wafer, and put a bundle of carbon fiber filaments (the diameter of carbon fiber filaments is any one of 5-8 μm, take 30 carbon fiber monofilaments as a bundle) ( Uniformly and neatly) wound on the position where the glue is coated on the silicon wafer, and wound into a row of carbon fiber filaments with a width of 5mm;

[0048] b. Adhesive companion piece: apply glue on the carbon fiber filaments on the opposite sides of the silicon wafer, and then stick a companion piece on the opposite sides of the area where the carbon fiber filaments are wound, to obtain a sample with the companion piece pasted;

[0049] c. Curing: Put the sample pasted with the accompanying sheet into a mold (preferably a mold made of polytetrafluoroethylene), clamp it with spring clips, heat and cure at 1...

Embodiment 3

[0053] A preparation method for a carbon fiber sample for Raman spectroscopic testing, comprising the following steps:

[0054] a. Silicon wafer gluing and wire winding: apply glue on the rectangular parallelepiped silicon wafer, and put a bundle of carbon fiber filaments (the diameter of carbon fiber filaments is any one of 5-8 μm, it is better to take 20 carbon fiber monofilaments) One bundle) (uniformly and neatly) wound on the position where the glue is coated on the silicon wafer, and wound into a row of carbon fiber filaments with a width of 3mm;

[0055] b. Adhesive companion piece: apply glue on the carbon fiber filaments on the opposite sides of the silicon wafer, and then stick a companion piece on the opposite sides of the area where the carbon fiber filaments are wound, to obtain a sample with the companion piece pasted;

[0056] c. Curing: Put the sample pasted with the accompanying sheet into a mold (preferably a mold made of polytetrafluoroethylene), clamp it wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com