Semiconductor structures and methods of forming them

A technology of semiconductor and stack structure, applied in the fields of semiconductor devices, semiconductor/solid-state device manufacturing, electrical components, etc., can solve the problems that the size of nanowires is difficult to be completely uniform, affect the performance of semiconductor devices, and the performance of transistors is different, and achieve consistent performance and thickness. Uniform, performance-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] As mentioned in the background art, the performance of the currently formed all-around gate transistors needs to be further improved.

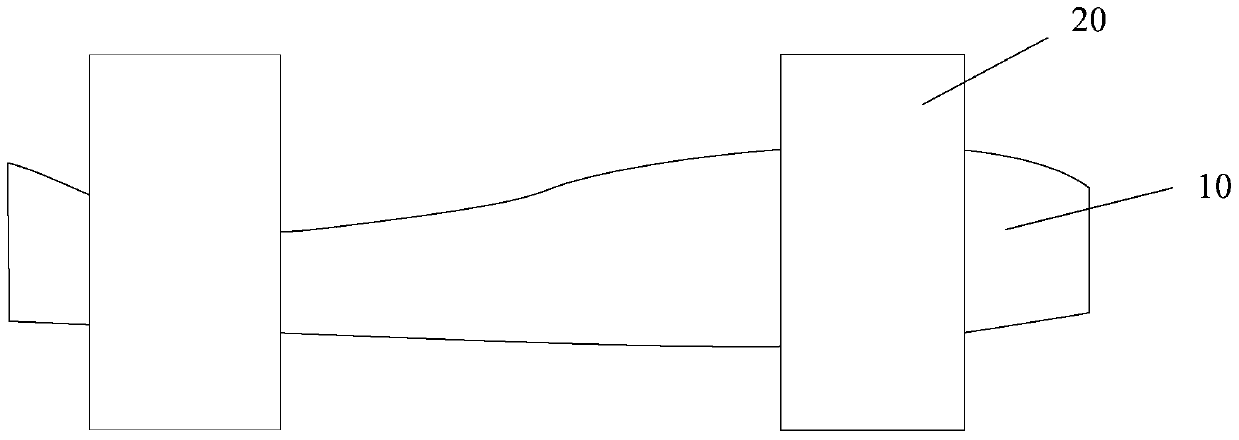

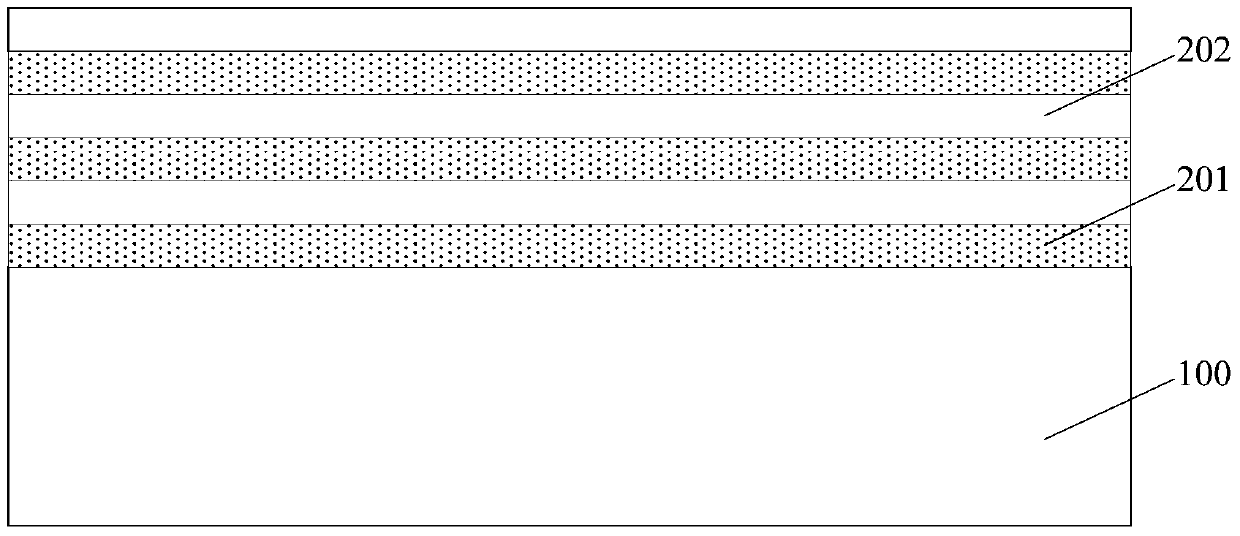

[0039] In an embodiment of the present invention, after the first semiconductor wire is formed, a second semiconductor layer is formed on the surface of the first semiconductor wire. The thickness of the second semiconductor layer is uniform, and as the channel layer of the field-effect transistor that fully surrounds the gate, compared with the gate structure directly formed on the first semiconductor line, the shape of the first semiconductor line has a greater impact on the performance of the transistor. The gate structure is formed on the surface of the second semiconductor layer, and the thickness of the second semiconductor layer is uniform, so that the performance of transistors formed at different positions will not be affected by the shape of the first semiconductor line.

[0040] In order to make the above objects, features an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com