Cover film for grape cultivation

A covering film and grape technology, which is applied in the field of covering film for grape planting, can solve the problems of early germination of grape branches and vines, and achieve the effect of simplifying precautions, good heat preservation effect and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

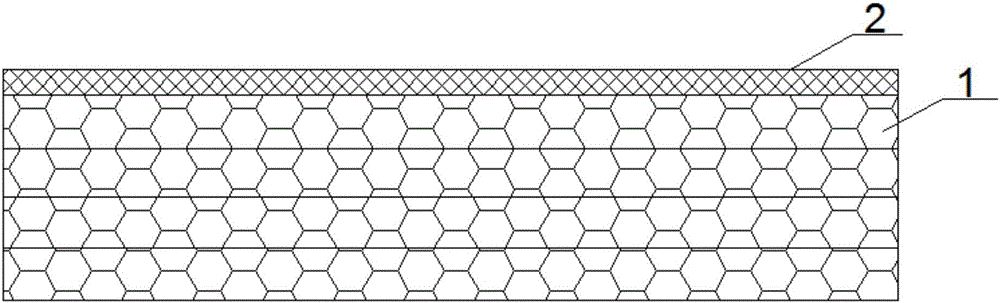

Embodiment 1

[0020] Example 1, as a preferred solution for the composition of air bubble film 1, the raw material composition of air bubble film 1 includes 85 parts of current 222 rubber material, 15 parts of high pressure PE10803, 25 parts of metallocene 1018, 8 parts of anti-aging master Material, 15 parts of flame retardant, the number of layers of air bubble film 1 in the air bubble film layer is four layers, the active film is bonded on the surface of one side of the air bubble film layer, and the active film is selected as aluminized film 1, and the covering film of this structure is used The film is used to cover grapes, the aluminized film 1 faces outward, and the air bubble film layer can play a role in heat preservation. The aluminized film 1 can reflect a part of sunlight, so as to ensure that the internal temperature of the covered area will not rise significantly. The germination date should follow a strict solar cycle. If the temperature is too high, the grapes will germinate ...

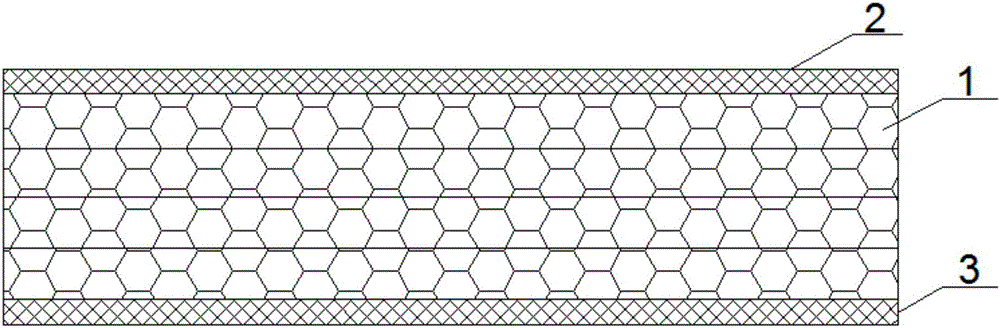

Embodiment 2

[0021] Embodiment 2, as the optimized embodiment of embodiment 1, the raw material composition of air bubble film and the number of parts thereof are constant, and effect film is bonded on the double-sided surface of air bubble film layer, and one side is aluminized film 2, and the other The side is PE film 3.

[0022] When applied to the covering of grape burial, when the aluminized film 2 faces outward and the PE film 3 faces inward, during the process of laying the covering film, the PE film 3 can protect the bubble film layer from abrasion, and the covering film can not only keep warm, but also Give full play to the reflective effect of the aluminized film 2, and finally keep the temperature within a reasonable range; when applied to greenhouse planting occasions, the cover film can be applied in reverse, that is, the PE film 3 faces the outside, the aluminized film 2 faces the inside, and the PE film 3 Choose black, PE film 3 can absorb the heat of sunlight, and its combi...

Embodiment 3

[0023] Embodiment 3, as another embodiment of the raw material composition of air bubble film 1 in embodiment 1 and embodiment 2, the raw material composition of air bubble film comprises 82 parts of extruded low-density polyethylene, 14 parts of high pressure PE10803, 22 parts metallocene 1018, 7 parts anti-aging masterbatch, 13 parts flame retardant.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com