Large reactor for preparing acetylene and synthesis gas through partial oxidation of hydrocarbon

An oxidation reaction and reactor technology, which is applied in hydrogen/synthesis gas production, fluid mixers, chemical instruments and methods, etc., can solve problems such as large water consumption and pollution, and achieve the effect of reducing the range of quenching nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

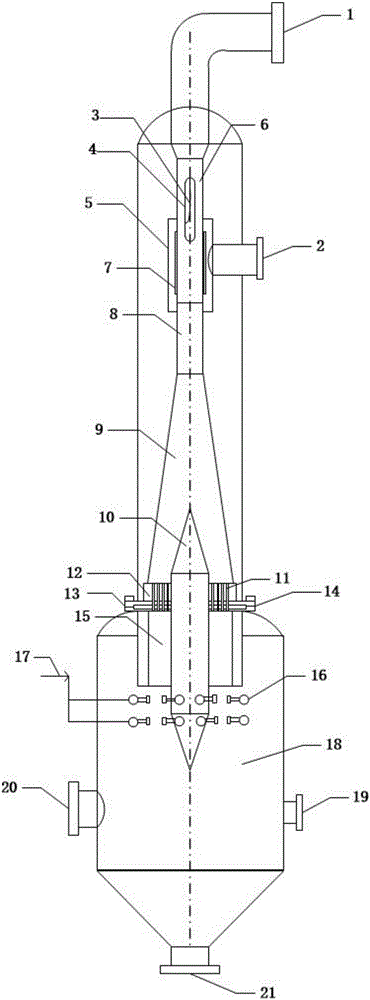

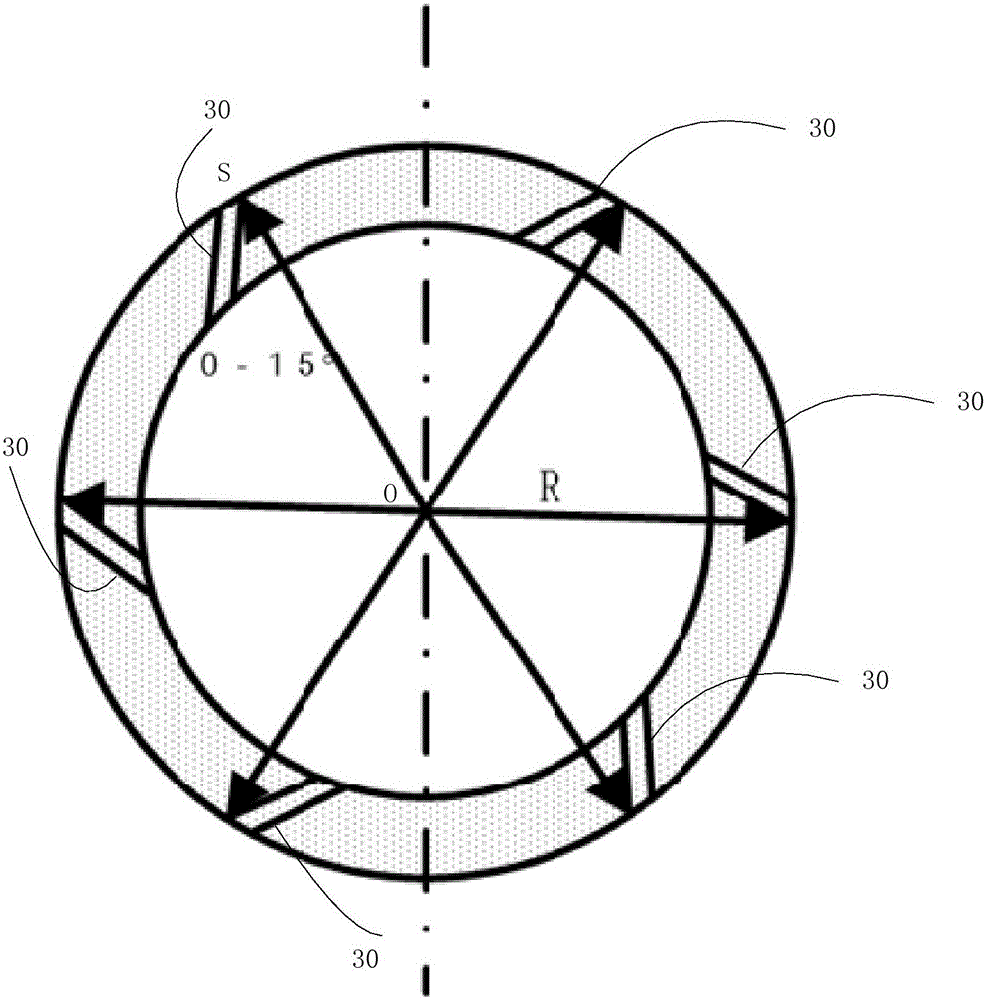

[0040] Embodiments according to the present invention will be described in detail with reference to the accompanying drawings. Here, it is to be noted that, in the drawings, the same reference numerals are assigned to components having substantially the same or similar structures and functions, and repeated descriptions about them will be omitted.

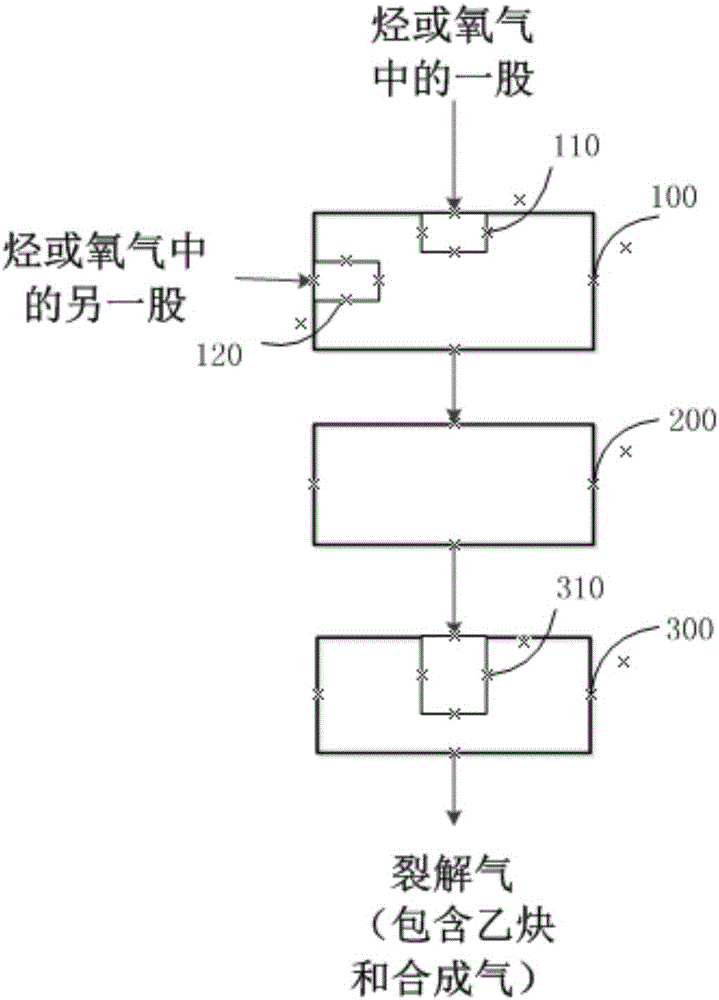

[0041] figure 1 A structural block diagram of a large-scale reactor for preparing acetylene and syngas by partial oxidation of hydrocarbons according to an embodiment of the present invention is shown.

[0042] Such as figure 1 As shown, the large-scale reactor for preparing acetylene and syngas by partial oxidation of hydrocarbons according to an embodiment of the present invention includes: a mixing zone 100 , a reaction zone 200 , and a quenching zone 300 .

[0043] The mixing zone 100 has a hydrocarbon inlet and an oxygen inlet, which are used to feed in hydrocarbon and oxygen respectively. The hydrocarbon and oxygen are unif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com