Method for manufacturing immersed square staggered arrangement tubular membrane bioreactor

A bioreactor and square technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problem of increased manufacturing costs, inability to perform reverse cleaning of membrane modules, and weakening the development of membrane contamination layers And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

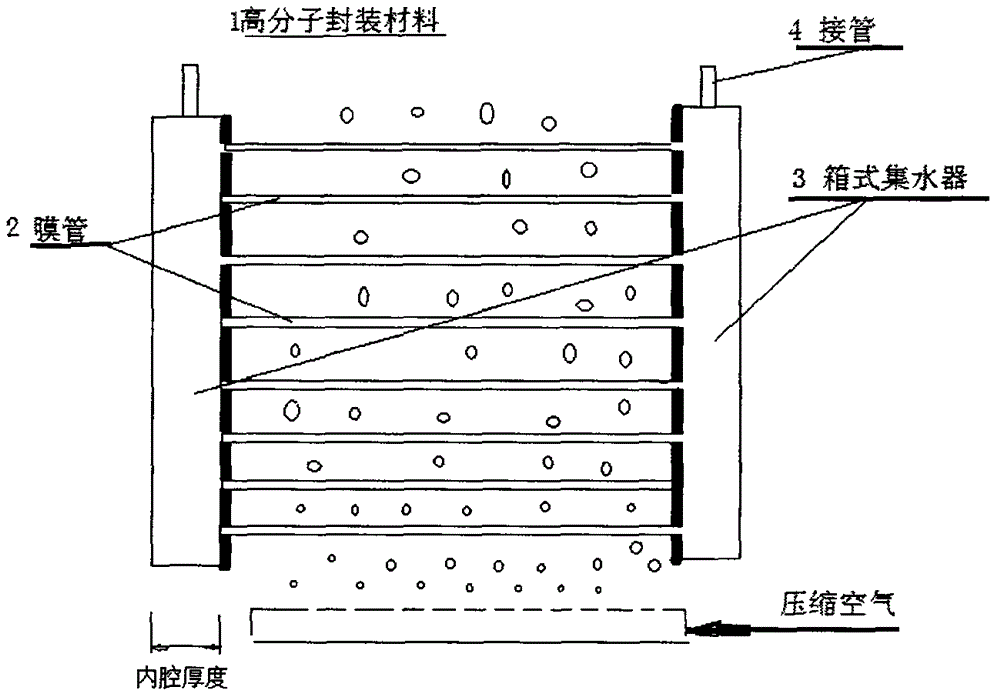

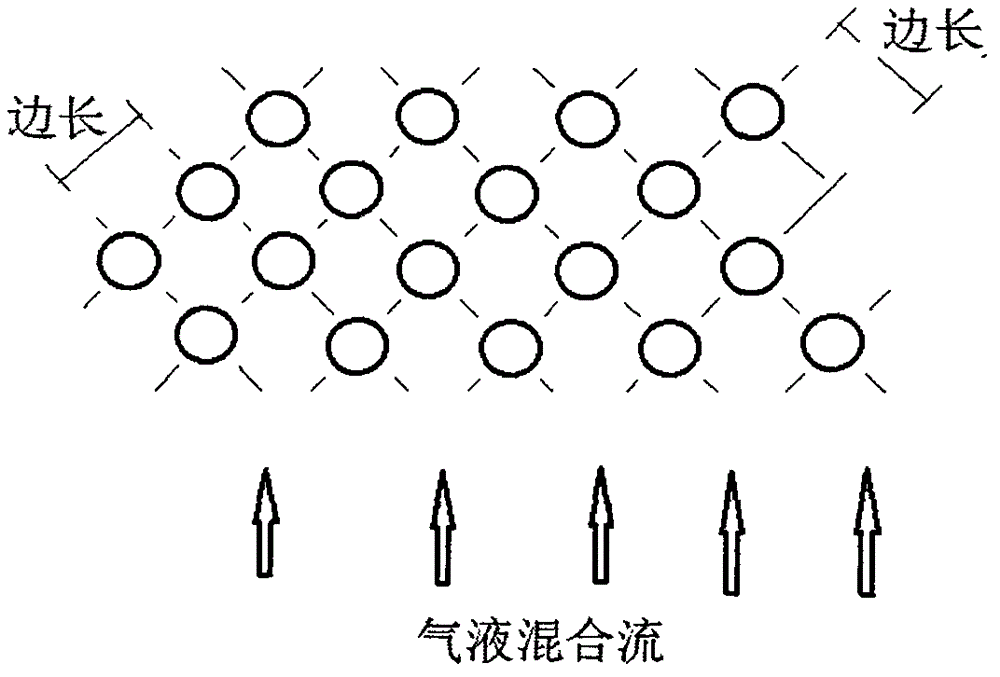

Embodiment 1

[0017] 400 tubes with inner diameter of 8mm and length of 1200mm are coated with polyvinylidene fluoride membrane, the effective membrane area is 12m 2 , according to the square staggered arrangement, the side length is 12mm, epoxy resin is used as the packaging material, the inner cavity thickness of the box-type water collector is 40mm, the connecting pipe of the left box-type water collector is connected with the inlet of the produced water pump, and the right box-type water collection The connecting pipe of the device is connected to the backwash pump, and the produced water is used for backwashing, and a compressed air aeration pipe is arranged at the lower part. The above-mentioned tubular MBR device is placed in a domestic sewage treatment tank, the COD of the sewage influent is 4000mg / L, the water temperature is 26°C, the aeration intensity is 22:1 (air-water ratio), the vacuum degree of the pump is 25kpa, and the output water 80min, backwashing with permeated water fo...

Embodiment 2

[0019] 400 tubes with inner diameter of 8mm and length of 1200mm are coated with polyvinylidene fluoride membrane, the effective membrane area is 12m 2 , according to the square staggered arrangement, the side length is 12mm, epoxy resin is used as the packaging material, the inner cavity thickness of the box-type water collector is 40mm, the connecting pipe of the left box-type water collector is connected with the inlet of the produced water pump, and the right box-type water collection The connecting pipe of the device is connected to the backwash pump, and the produced water is used for backwashing, and a compressed air aeration pipe is arranged at the lower part. The above-mentioned tubular MBR device is placed in a domestic sewage treatment tank. The COD of the sewage influent is 4000mg / L, the water temperature is 26°C, the aeration intensity is 26:1 (air-water ratio), and the vacuum degree of the pump is 30kpa. 60min, backwashing with permeated water for 50s at 80kpa pr...

Embodiment 3

[0021] 400 tubes with inner diameter of 6mm and length of 1200mm are coated with polyvinylidene fluoride membrane inside and outside, the effective membrane area is 9m 2 , according to the square staggered arrangement, the side length is 10mm, epoxy resin is used as the packaging material, the inner cavity thickness of the box-type water collector is 40mm, the connecting pipe of the left box-type water collector is connected with the inlet of the produced water pump, and the right box-type water collection The connecting pipe of the device is connected to the backwash pump, and the produced water is used for backwashing, and a compressed air aeration pipe is arranged at the lower part. The above-mentioned tubular MBR device is placed in a domestic sewage treatment tank. The COD of the sewage influent is 4000mg / L, the water temperature is 26°C, the aeration intensity is 28:1 (air-water ratio), and the vacuum degree of the pump is 30kpa. 60min, backwashing with permeated water f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com