Method for co-production of sodium methoxide through methanol gas phase dehydration dimethyl ether manufacturing device and device thereof

A technology of dimethyl ether and sodium methoxide, which is applied in the field of co-production of sodium methoxide in a methanol gas phase dehydration device to produce dimethyl ether, can solve the problems of heat energy consumption, high economic cost, single product, etc., and achieve the effect of reducing steam consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

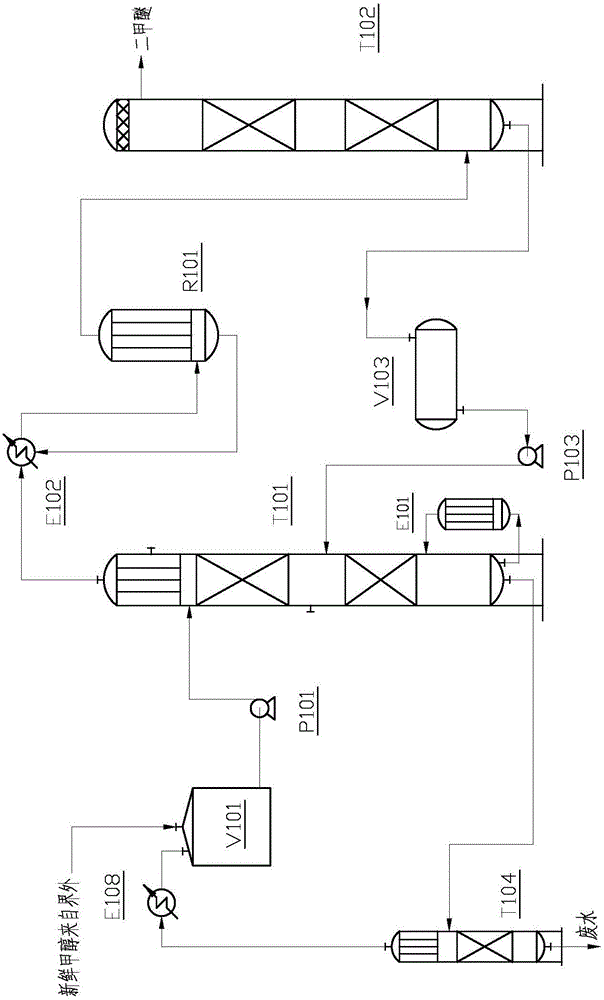

[0027] Embodiment 1 DME production example

[0028] Such as figure 1 As shown, this device is an annual output of 100,000 tons of dimethyl ether device: First, the raw material methanol in the raw material methanol intermediate storage tank V101 is sent to the feed port B of the methanol rectification tower T101 through the methanol feed pump P101, and the initial feed The mass concentration of methanol is ≧99.8%, and the temperature is 135°C. The tank of the methanol rectification tower T101 is equipped with a reboiler, which is heated with water vapor to vaporize the methanol into methanol vapor and rises along the tower. The methanol vapor is sent from the upper part of the methanol rectification tower T101. The methanol steam has a water content of 5%. After heat exchange between the heat exchanger E102 and the effluent of the reactor R101, the temperature is raised to 230°C, the pressure is 2MPa, and the mass concentration is ≧95%. Then it enters the reactor R101 for dehy...

Embodiment 2

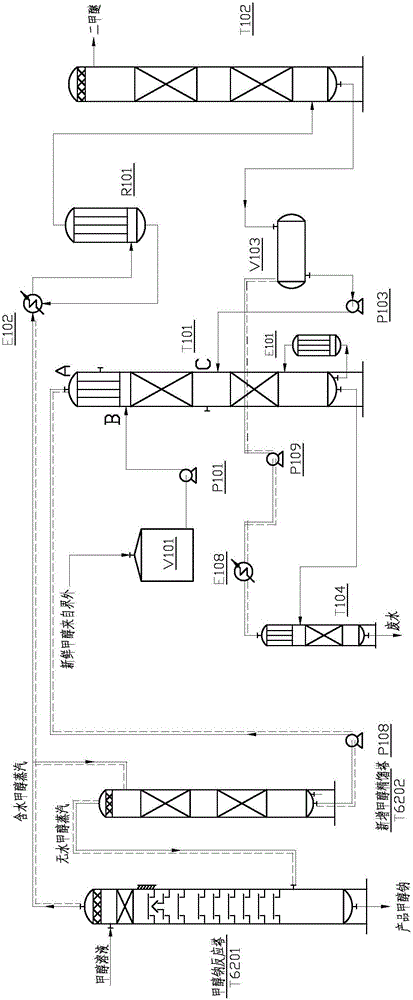

[0034] Example 2 Example of co-production of sodium methoxide with methanol vapor phase dehydration plant for dimethyl ether production

[0035] Such as figure 2 As shown, this device is a sodium methoxide device with an annual output of 100,000 tons of dimethyl ether and 40,000 tons: First, the raw material methanol in the raw material methanol intermediate storage tank V101 is sent to the methanol rectification tower T101 through the methanol feed pump P101. Feed port B, the mass concentration of the initial feed methanol is ≧99.8%, the temperature is 135°C, the tank of the methanol rectification tower T101 is equipped with a reboiler, heated by water steam to vaporize methanol into methanol vapor and rise along the tower for rectification.

[0036] The anhydrous methanol vapor generated at the top of the newly added methanol rectification tower T6202 is sent to the bottom of the sodium methoxide reaction tower T6201 to react with the formic soda solution entering from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com