Vacuum infusion resin and preparation method and application thereof

A vacuum introduction and resin technology, applied in the field of resin, can solve the problems of short pot life, insufficient toughness, insufficient penetration, etc., and achieve the effect of moderate curing time, excellent performance and avoiding waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

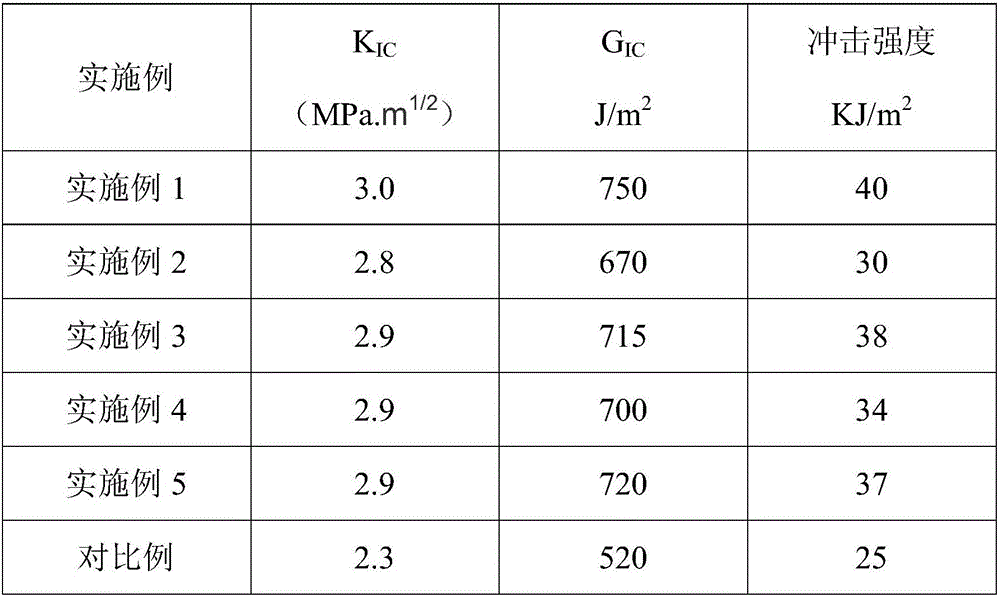

Examples

Embodiment 1

[0026] 1) Preparation of nano rubber particle mixture: take 100 parts of bisphenol A epoxy resin into the container by mass, add 20 parts of nano rubber particles, 0.8 parts of wetting and dispersing agent, and 1.5 parts of coupling agent , Stirring at a temperature of 70° C. at a stirring speed of 2000 r / min for 1 h, and cooling to room temperature to prepare a mixture of nano rubber particles.

[0027] 2) Preparation of toughened epoxy resin: add 15 parts of dispersed nano rubber particle mixture and 10 parts of 1,6-hexanediol to 90 parts of bisphenol F epoxy resin in parts by mass Diglycidyl ether and 1,4-butanediol diglycidyl ether are a 1:1 fatty glycidyl ether active diluent mixed at room temperature at 2000r / min for high-speed stirring for 0.5-1h to make the mixture uniform.

[0028] 3) In parts by mass, add 115 parts of curing agent tetramethylguanidine to the above-mentioned mixed solution, the stirring speed is 1000-1500r / min under normal temperature and long pressure, th...

Embodiment 2

[0030] 1) Preparation of nano rubber particle mixture: Take 100 parts of bisphenol A epoxy resin into the container by mass, add 30 parts of nano rubber particles, 1 part of wetting and dispersing agent, and 2 parts of coupling agent , Stirring for 1.2 h at a temperature of 80° C. at a stirring speed of 2000 r / min, and cooling to room temperature to prepare a mixture of nano rubber particles.

[0031] 2) Preparation of toughened epoxy resin: add 10 parts of dispersed nano rubber particle mixture and 5 parts of 1,6-hexanediol to 90 parts of bisphenol F epoxy resin by mass parts Diglycidyl ether and 1,4-butanediol diglycidyl ether are a 1:1 fatty glycidyl ether active diluent mixed at room temperature at 2000r / min for high-speed stirring for 0.5-1h to make the mixture uniform.

[0032] 3) Add 105 parts of the curing agent tetramethylguanidine in the above-mentioned mixture by parts by mass, and the stirring speed is 1000-1500r / min under normal temperature and long pressure, and the s...

Embodiment 3

[0034] 1) Preparation of nano rubber particle mixture: Take 100 parts of bisphenol A epoxy resin into the container by mass, add 35 parts of nano rubber particles, 1.2 parts of wetting and dispersing agent, and 2.5 parts of coupling agent , Stirring at a temperature of 90° C. at a stirring speed of 2000 r / min for 1.5 h, and cooling to room temperature to prepare a mixture of nano rubber particles.

[0035] 2) Preparation of toughened epoxy resin: add 20 parts of dispersed nano rubber particle mixture and 15 parts of butyl glycidyl ether to 90 parts of bisphenol F epoxy resin in parts by mass. ,4-Butanediol diglycidyl ether is a 1:1 mixture of fatty glycidyl ether active diluent, at room temperature using 2000r / min for high-speed stirring for 0.5-1h to make the mixture uniform.

[0036] 3) In parts by mass, add 125 parts of curing agent tetramethylguanidine to the above-mentioned mixed solution, the stirring speed is 1000-1500r / min under normal temperature and long pressure, the sti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com