Porous tungsten blank with gradient continuous changing porosity degrees and preparation method

A gradient change, porous tungsten technology, applied in the field of powder metallurgy, can solve problems such as complex spatial geometric features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Example 1: Preparation of Porous Tungsten Blanks with Continuously Varying Porosity Gradients for High Temperatures

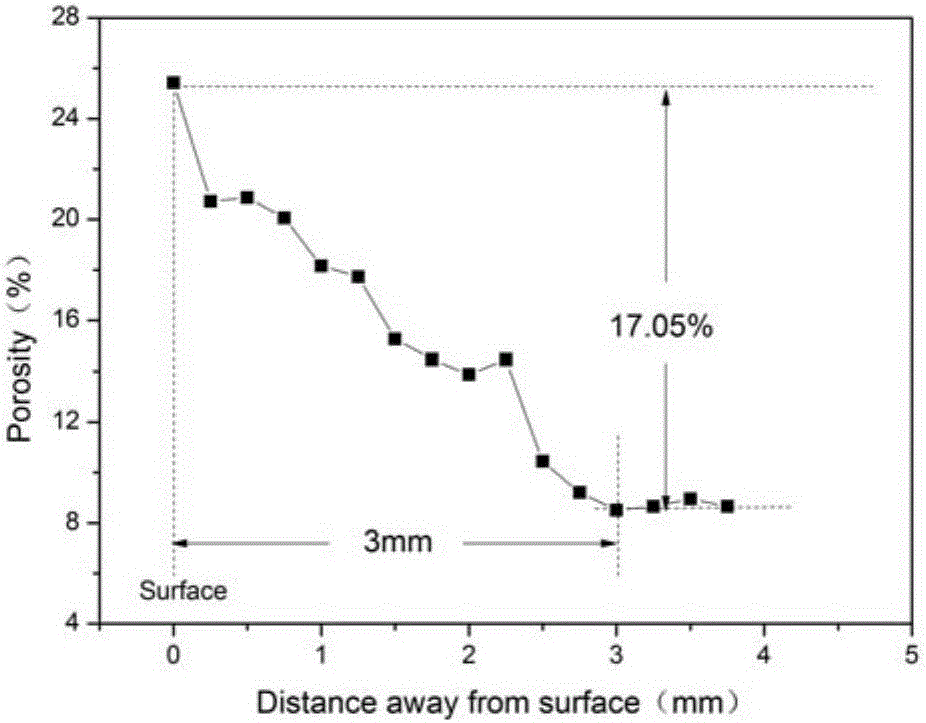

[0022] Mix 70% (mass fraction) 10-micron tungsten powder with 30% (mass fraction) 5-micron tungsten powder in a ball mill for 6-8 hours, then put the mixed tungsten powder into a rubber sleeve and perform cold isostatic at 300MPa Press treatment, the relative density of the green compact is 57%. The tungsten powder compacts were placed in a tubular electric furnace with flowing nitrogen for oxidation-gasification treatment of tungsten. In order to realize the oxidation-gasification treatment effect of the tungsten component, the nitrogen gas was introduced into a buffer bottle containing water to humidify before entering the electric tube furnace. The tungsten component was subjected to "oxidation-gasification" treatment for 1.5 hours at 970°C, and cooled with the furnace. It was then reduced in high purity hydrogen at 900°C for 1 hour. Finally, it wa...

Embodiment 2

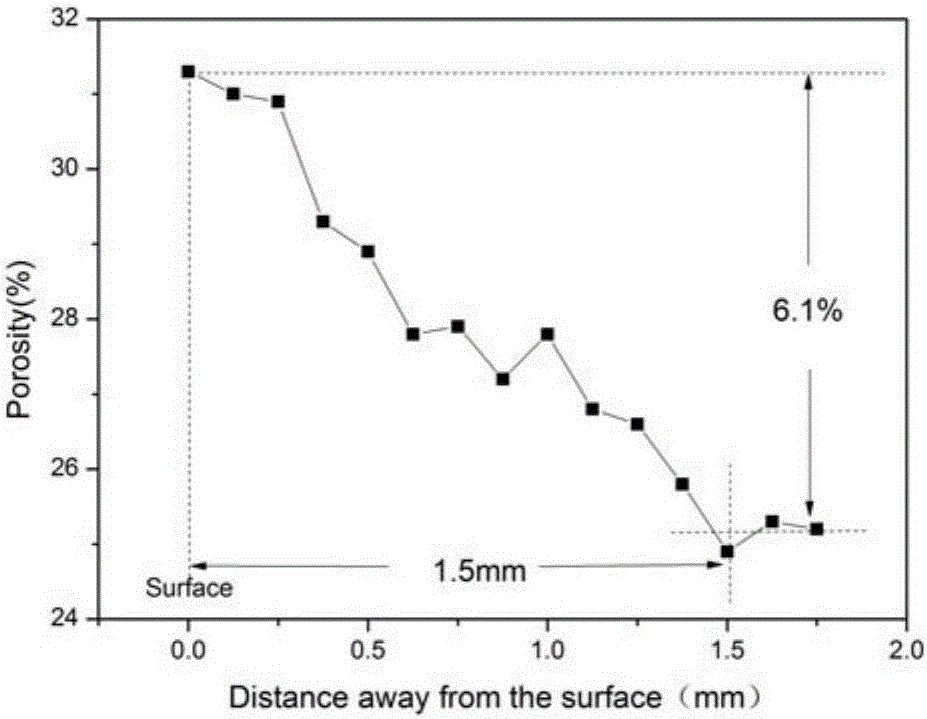

[0023] Example 2: Preparation of Porous Tungsten Blanks with Continuously Varying Porosity Gradients at Room Temperature

[0024] First, mix 60% (mass fraction) of 10-micron tungsten powder with 40% (mass fraction) of 5-micron tungsten powder in a ball mill for 6-8 hours. Block samples were formed under pressure of 600-650 MPa, and the relative density of green compacts was 78%. The tungsten powder compacts were placed in a tubular electric furnace with flowing nitrogen for oxidation-gasification treatment of tungsten. In order to realize the oxidation-gasification treatment effect of the tungsten component, the nitrogen gas was introduced into a buffer bottle containing water to humidify before entering the electric tube furnace. The tungsten component was subjected to "oxidation-gasification" treatment for 2 hours at 870°C, and cooled with the furnace. It was then reduced in high purity hydrogen at 920°C for 1 hour. The porosity distribution in the porous tungsten blank i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com