Nano-diamond reinforced titanium-based composite material as well as preparation method and application thereof

A titanium-based composite material and nano-diamond technology, which is applied in medical science, prosthesis, surgery, etc., can solve the problems of cytotoxicity and poor biological performance, achieve high hardness, strength and plasticity, overcome poor mechanical properties, and have good biological properties. The effect of biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

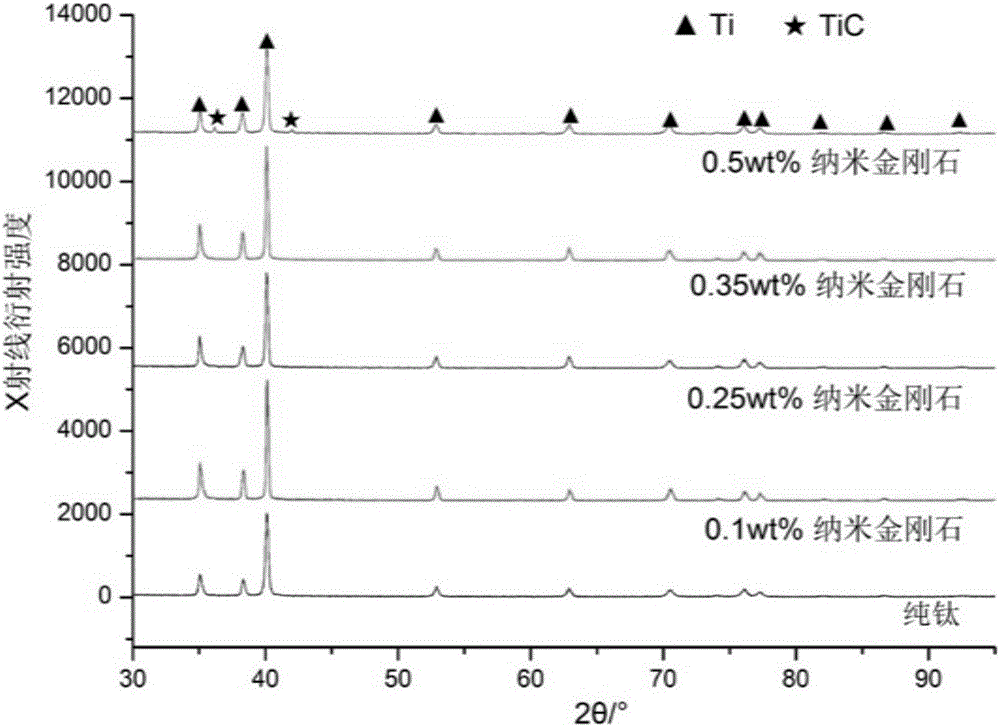

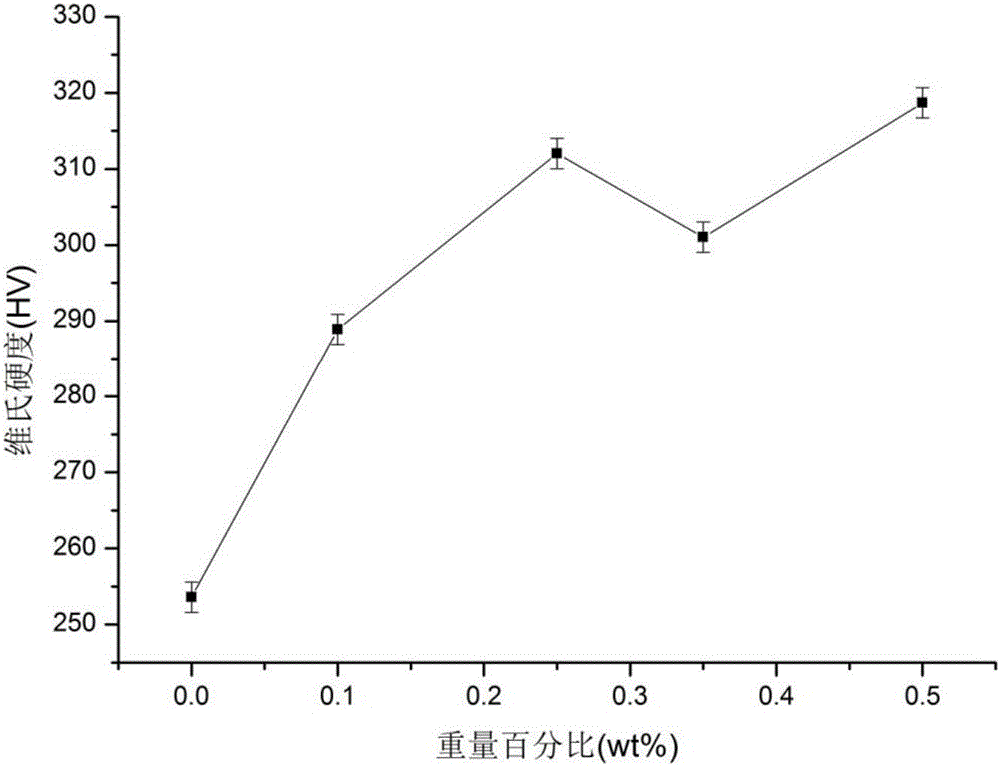

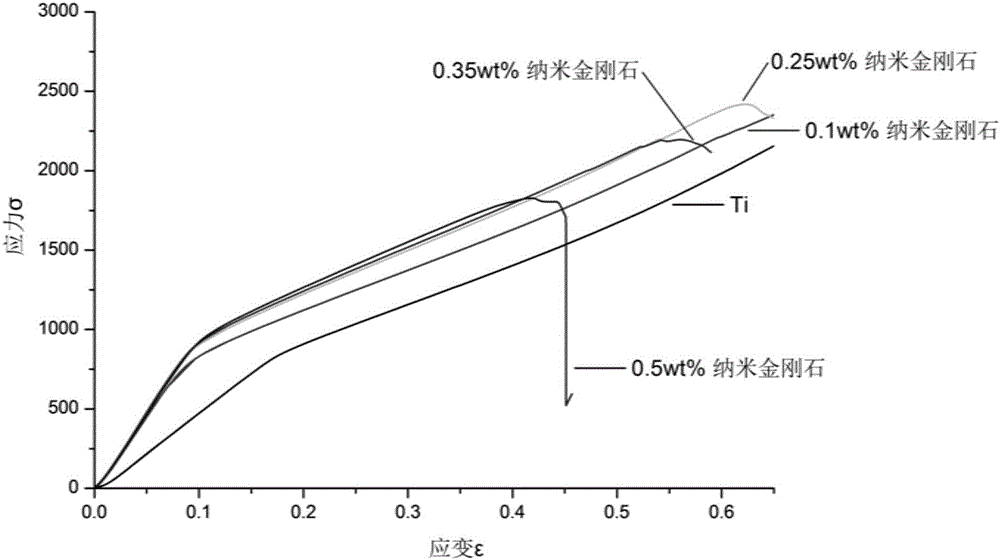

[0047] Nano-diamond-reinforced titanium-based composites are produced by spark plasma technology sintering, using nano-diamond powder and pure titanium powder as raw materials (purity is 99%), wherein the grain size of nano-diamond is 5.0nm, and the grain size of pure titanium powder is 48μm (300 mesh), nano powder and micro powder respectively. A cylindrical composite material sintered body with a diameter of 10 mm and a height of 12 mm was produced.

[0048] Specific steps are as follows:

[0049] (1) weighing 10g300 purpose pure titanium powder (purity is 99%) and the nano-diamond powder that mass fraction is 0.25wt%, the nano-diamond powder that mass fraction is 0.25wt% is placed in the beaker, adds dehydrated alcohol, adds Sodium lauryl sulfate is used as a surfactant, which is oscillated by an ultrasonic oscillator and a needle oscillator successively. Then add the weighed titanium powder into the oscillated nano-diamond powder, and repeat the above-mentioned oscillati...

Embodiment 2

[0055] Vacuum sintering technology produces nano-diamond-reinforced titanium-based composite materials, using nano-diamond powder and pure titanium powder as raw materials (purity is 99%), wherein the particle size of nano-diamond is 20nm, and the particle size of pure titanium powder is 106μm (150 mesh) . A cylindrical composite material sintered body with a diameter of 20 mm and a height of 10 mm was produced. Specific steps are as follows:

[0056] (1) weighing 100g 150 purpose pure titanium powder (purity is 99%) and mass fraction is the nano-diamond powder of 0.5wt%, the nano-diamond powder that mass fraction is 0.5wt% is placed in the beaker, adds dehydrated alcohol, Add sodium lauryl sulfate as a surfactant, and vibrate successively through an ultrasonic oscillator and a needle oscillator. Then add the weighed titanium powder into the oscillated nano-diamond powder, and repeat the above-mentioned oscillating operation.

[0057] (2) Get the liquid after the initial mi...

Embodiment 3

[0062] Nano-diamond-reinforced titanium-based composite materials are produced by hot-pressing sintering technology, using nano-diamond powder and titanium-aluminum-vanadium (Ti6Al4V) powder as raw materials (purity is 99.5%), wherein the grain size of nano-diamond is 50nm, and the particle size of titanium-aluminum-vanadium powder The size is 13 μm (1000 mesh), and a cylindrical composite material sintered body with a diameter of 30 mm and a height of 20 mm is produced.

[0063] Specific steps are as follows:

[0064] (1) Weighing 100g 300 mesh titanium aluminum vanadium (Ti6Al4V) powder powder (purity is 99%) and mass fraction are respectively the nanometer diamond powder of 0.1wt%, the nanometer diamond powder that massfraction is 0.1wt% is placed in the beaker , add absolute ethanol, add sodium lauryl sulfate as a surfactant, and vibrate through an ultrasonic oscillator and a needle oscillator successively. Then add the weighed titanium alloy powder into the oscillated na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com