High-temperature wear-resistant and corrosion-resistant steel powder for additive manufacturing and additive manufacturing method

A technology for additive manufacturing and corrosion-resistant steel, which is applied in the field of additive manufacturing to achieve the effects of higher hardness, good tempering stability, and significant thermal fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

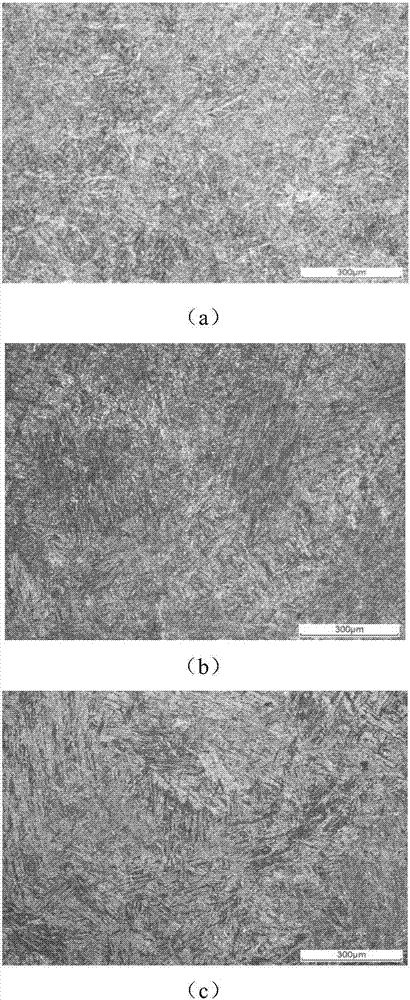

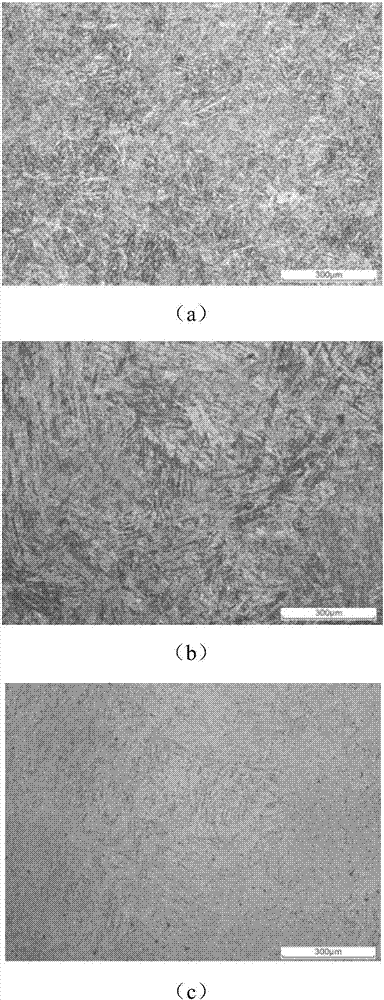

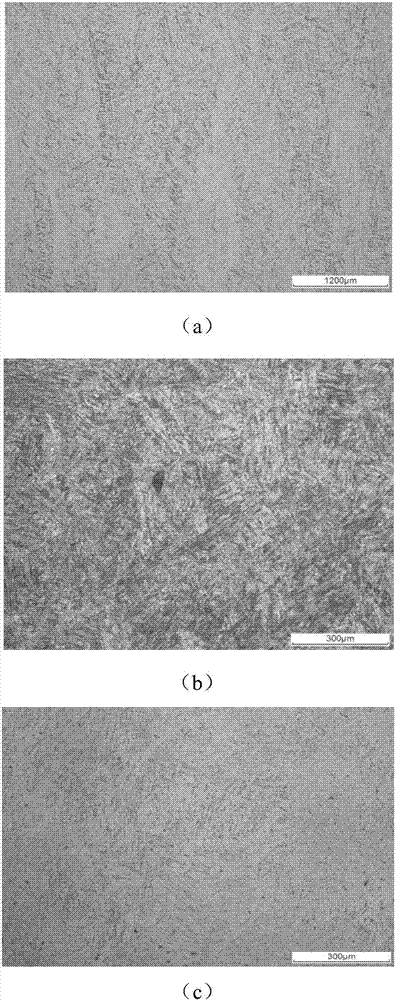

Examples

Embodiment 1

[0044] Prepare high-performance high-temperature wear-resistant and corrosion-resistant steel powder for additive manufacturing, the mass percentage content of each element in the powder material is:

[0045] element

C

mn

Si

Cr

Ni

Mo

V

Nb

Fe

Wt.%

0.2

1.5

0.6

9.0

6.0

1.0

0.2

0.3

margin

[0046] Additive manufacturing methods are:

[0047] Steel powder materials with a particle size of 15-53 μm and a purity of ≥99.99% were kept at 120°C for 4 hours, and then put into the powder cylinder of the additive manufacturing equipment. Mill the surface of the H13 steel substrate with a size of 250mm (length) × 250mm (width) × 20mm (thickness) with a milling machine until the surface roughness is not greater than Ra6.3, and clean the surface of the substrate with acetone, and install it after drying. Into the additive manufacturing equipment fixed. Use the subsection software to obtain slices of each layer...

Embodiment 2

[0049] The steel powder in the above-mentioned embodiment 1 was replaced with the steel powder having the following component contents, and the parts were formed, and the other processes were the same.

[0050] element

Embodiment 3

[0052]The steel powder in the above-mentioned embodiment 1 was replaced with the steel powder having the following component contents, and the parts were formed, and the other processes were the same.

[0053] element

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com