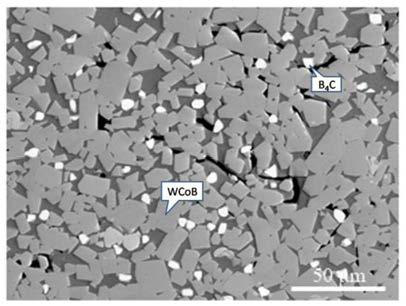

a wcob-b 4 C preparation method of ceramic matrix composite material

A composite material, wcob-b4c technology, applied in the field of preparation of WCoB-B4C ceramic matrix composite materials, can solve the problems of high brittleness, easy formation of coarse grains, high density of WCoB-based cermets, etc. The effect of good high temperature wear performance and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A WCoB-B of the present invention 4 The preparation method of C ceramic matrix composite material, comprises the following steps:

[0031] S1. Weigh W powder, Co powder, C powder and B powder for powder mixing, wherein the mass fraction of W powder is 65.6-69.1%, the mass fraction of Co powder is 26.5-28.8%, and the mass fraction of C powder is 0.5% %, the mass fraction of B powder is 4.0-5.2%;

[0032] S2. Put the mixed powder prepared in step S1 into a ball mill tank for ball milling;

[0033] Among them, the ball milling process parameters are: wet milling in a ball mill for 20-40 hours, wherein the ball milling medium is absolute ethanol, the ball-to-material ratio is 5:1, and the balls are silicon nitride balls.

[0034] S3. After the ball milling in step S2 is completed, put the ball milled powder into a vacuum drying oven to dry, keep it warm at 70°C for 8 hours, and then pass the dried powder through a 150-200-mesh sieve;

[0035] S4, filling the mixed powder...

Embodiment 1

[0041] Select typical WCoB-B 4 The formula of C ceramic matrix composite material, the mass fraction of its raw material component is: 68% W powder (purity: 99.99%, particle size: 100 mesh), 27% Co powder (purity: 99.9%, particle size: 100 mesh) , 0.5% C powder (purity: 99.9%, particle size: 200 mesh), 4.5% B powder (purity: 99.99%, particle size: 200 mesh);

[0042] (2) Each powder is weighed by an electronic balance with an accuracy of 0.1 mg, and put into a ball mill jar for ball milling, wet milling for 20 hours, the ball milling medium is absolute ethanol, and the ball-to-material ratio is 5:1;

[0043](3) Put the ball-milled powder into a vacuum drying oven to dry, keep it warm at 60°C for 8 hours, and then pass the dried powder through a 150-mesh sieve;

[0044] (4) Fill the mixed powder into the mould, press and form, the pressing pressure is 150MPa, and the holding pressure is 5min;

[0045] (5) Put the compact into 10 -1 Sintering was carried out in a Pa vacuum si...

Embodiment 2

[0054] (1) Select a typical WCoB-B 4 The formula of C ceramic matrix composite material, the mass fraction of its raw material components is: 68% W powder (purity: 99.99%, particle size: 100 mesh), 27% Co powder (purity: 99.9%, particle size: 100 mesh) , 0.5% C powder (purity: 99.9%, particle size: 200 mesh), 4.5% B powder (purity: 99.99%, particle size: 200 mesh);

[0055] (2) Each powder is weighed by an electronic balance with an accuracy of 0.1 mg, and put into a ball mill tank for ball milling, wet milling for 40 hours, the ball milling medium is absolute ethanol, and the ball-to-material ratio is 5:1;

[0056] (3) Put the ball-milled powder into a vacuum drying oven to dry, keep it warm at 70°C for 8 hours, and then pass the dried powder through a 180-mesh sieve;

[0057] (4) Fill the mixed powder into the mould, press and form, the pressing pressure is 100MPa, and the holding pressure is 10min;

[0058] (5) Put the compact into a 10-1Pa vacuum sintering furnace for si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com