A kind of high-performance metal-ceramic composite powder used as thermal spraying structure feeding material and its preparation method

A metal-ceramic composite, high-performance technology, applied in metal processing equipment, metal material coating technology, coating and other directions, can solve the problem of nano powder with large specific surface area, easy adsorption on the wall of the powder feeding tube, small particle size of nano powder, etc. problems, to achieve the effect of low powder utilization, wide particle size distribution and high compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

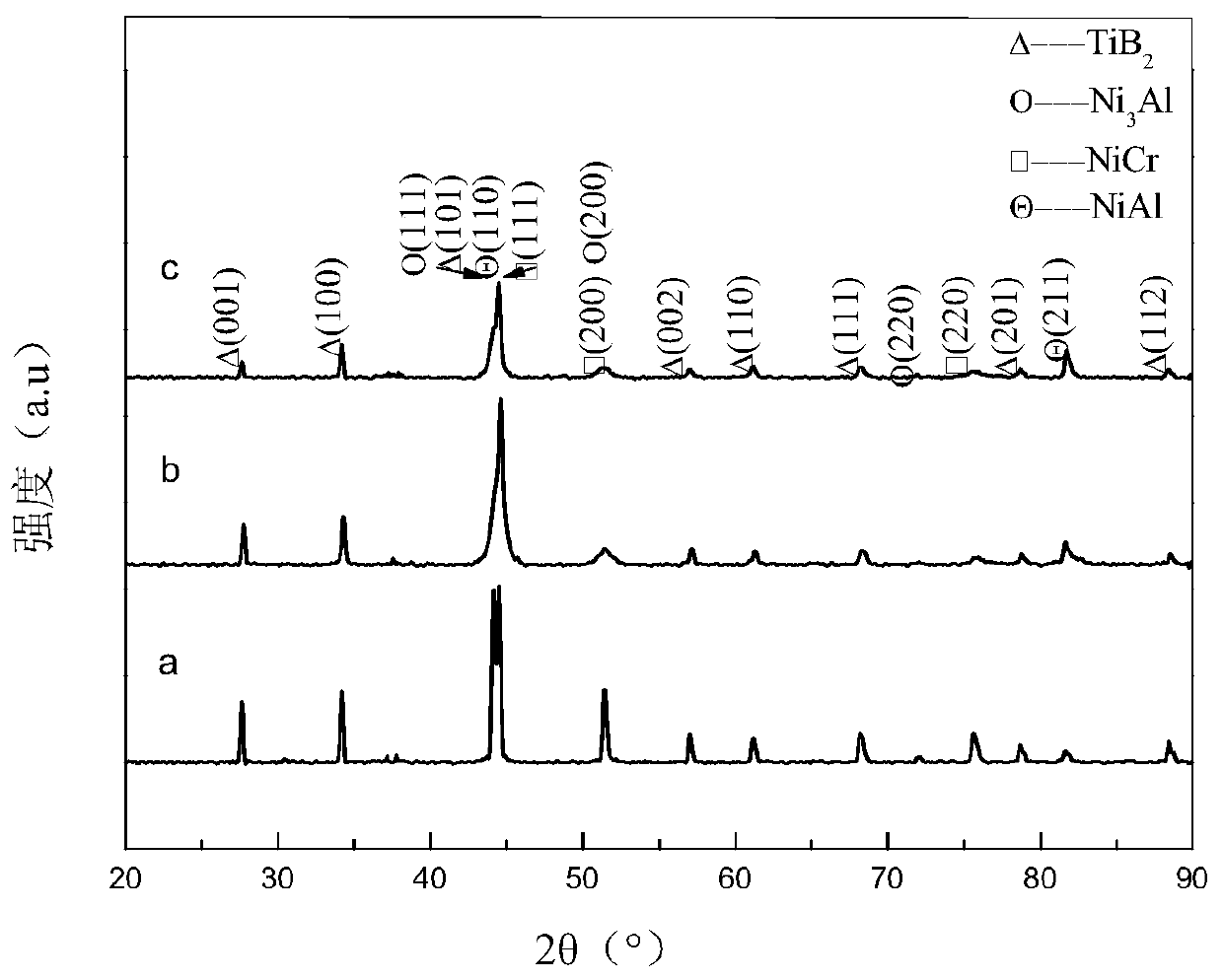

[0056] A method for preparing a high-performance cermet nanocomposite powder used as a thermal spraying structure feed, i.e. a nanocomposite structure feed, comprising the following steps:

[0057] 1) 40wt.%TiB 2 Powder (median particle diameter D50=3~5 μ m, purity 99.5%) and 60wt.% NiCrCoAlY powder (NiCrCoAlY nickel-based commercial spray powder (-320 / +500 mesh fine powder) produced by Chengdu Daguang Thermal Spray Material Co., Ltd.) Put into the mixer and pre-mix for 12h, the speed of the mixer is 80r / min, to obtain NiCrCoAlY-TiB 2 mixed powder;

[0058] 2) NiCrCoAlY-TiB obtained in step 1) 2 Put the mixed powder and GCr15 balls into the ball mill, GCr15 balls and NiCrCoAlY-TiB 2 The mass ratio of mixed powder is 1:10, and add dehydrated alcohol as process control agent, wherein, dehydrated alcohol and NiCrCoAlY-TiB 2 The mass ratio of the mixed powder is 0.6:1. In the atmosphere of high-purity argon as the protective gas, the KEQ-2L omnidirectional planetary ball mill ...

Embodiment 2

[0065] A method for preparing a high-performance cermet nanocomposite powder used as a thermal spraying structure feed, i.e. a nanocomposite structure feed, comprising the following steps:

[0066] 1) 40wt.%TiB 2 The powder and 60wt.% NiCrCoAlY powder are put into the blender and pre-mixed for 12h, and the speed of the blender is 80r / min to obtain NiCrCoAlY-TiB 2 mixed powder;

[0067] 2) NiCrCoAlY-TiB obtained in step 1) 2 Put the mixed powder and GCr15 balls into the ball mill, GCr15 balls and NiCrCoAlY-TiB 2 The mass ratio of mixed powder is 1:10, and add dehydrated alcohol as process control agent, wherein, dehydrated alcohol and NiCrCoAlY-TiB 2 The mass ratio of the mixed powder is 0.3:1. In the atmosphere of high-purity argon as the protective gas, use KEQ-2L omni-directional planetary ball mill to carry out wet milling for 12 hours, and the speed of the ball mill is 350r / min to obtain composite powder A;

[0068] 3) Put the composite powder A obtained in step 2) int...

Embodiment 3

[0074] A method for preparing a high-performance cermet nanocomposite powder used as a thermal spraying structure feed, i.e. a nanocomposite structure feed, comprising the following steps:

[0075] 1) 40wt.%TiB 2 The powder and 60wt.% NiCrCoAlY powder are put into the blender and pre-mixed for 12h, and the speed of the blender is 80r / min to obtain NiCrCoAlY-TiB 2 mixed powder;

[0076] 2) NiCrCoAlY-TiB obtained in step 1) 2 Put the mixed powder and GCr15 balls into the ball mill, GCr15 balls and NiCrCoAlY-TiB 2 The mass ratio of mixed powder is 1:10, and add dehydrated alcohol as process control agent, wherein, dehydrated alcohol and NiCrCoAlY-TiB 2 The mass ratio of the mixed powder is 0.3:1. In the atmosphere of high-purity argon as the protective gas, use KEQ-2L omni-directional planetary ball mill to carry out wet milling for 12 hours, and the speed of the ball mill is 350r / min to obtain composite powder A;

[0077] 3) Put the composite powder A obtained in step 2) int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com