Rusting passivator

A passivating agent and accelerator technology, applied in the direction of metal material coating process, etc., can solve the problems of secondary corrosion of steel surface, inability to form protective film, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] The present invention will be further described below in conjunction with embodiments:

[0008] First dissolve 20KG of tannic acid with 100KG of 50℃ warm water for use, take 5KG of acrylic emulsion and 210KG of phosphoric acid into the stirring tank, start stirring at low speed, add 25KG of ethylene glycol butyl ether, dissolved tannic acid, Lactic acid 20KG, isopropanol 80KG, anhydrous ethanol 200KG and water 325KG, stir evenly. The measured indicators are as follows: solid content 45±1%; viscosity ≤100; specific gravity 1.2±0.02; PH 2~3; 30 minutes of surface drying; 24 hours of actual drying; 24 hours of coating time; solid content of 46.8%; Brookfield viscosity less than 500mPa.S; water resistance of the coating film (48h): no blistering, shedding and discoloration; gasoline resistance (48h): no change; freeze-thaw stability (3 times) no change.

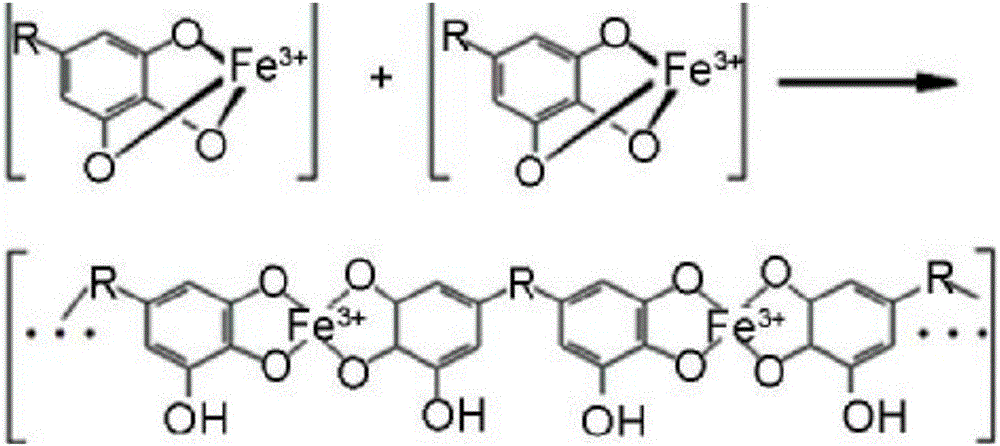

[0009] In the above scheme, tannic acid is a polyacid containing both hydroxyl and carboxyl groups. Its molecular weight is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| Brookfield viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com