Fireproofing, heat insulating and decorating integrated wallboard of house in oceanographic engineering

A technology of fire prevention and thermal insulation, marine engineering, applied in the field of building materials, can solve the problems of low service life, corrosion resistance, erosion resistance, humidity and heat resistance, can not adapt to harsh marine climate environment, high maintenance cost, etc., to achieve long service life , colorful and eye-catching, low maintenance cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

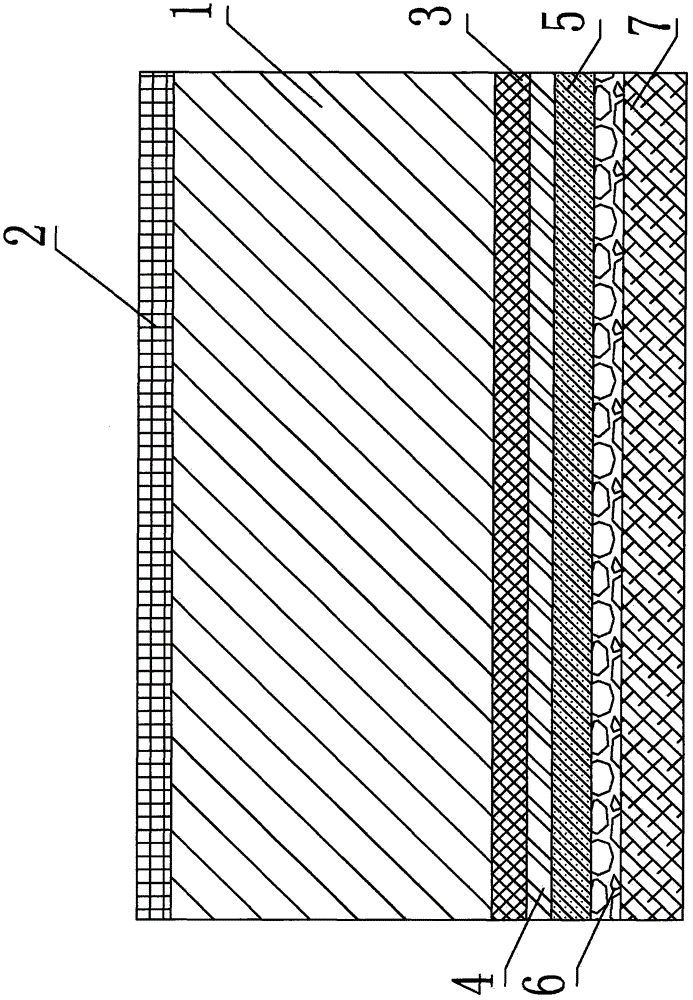

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] As shown in Figure 1, the fireproof, thermal insulation and decoration integrated house wallboard for marine engineering includes an ordinary Portland cement polystyrene foam slurry layer 1, which is characterized in that: the ordinary Portland cement polystyrene One side of the foam slurry layer 1 is bonded to the grid-shaped glass fiber polytetrafluoroethylene composite needle felt reinforcement layer 2, and the other side is bonded to the aluminum alloy plate 4 through the ordinary portland cement cementitious slurry layer 3, and the aluminum There is an anti-corrosion layer 5 on the other side of the alloy plate 4, and there is a layer of copolymerized water-soluble resin adhesive layer 6 on the anti-corrosion layer 5, and there is a layer of aramid fiber flocking layer 7 on the copolymerized water-soluble resin adhesive layer 6.

[0019] The thickness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com