Manufacturing method of flocked stainless steel spraying decoration plate for oceanographic engineering

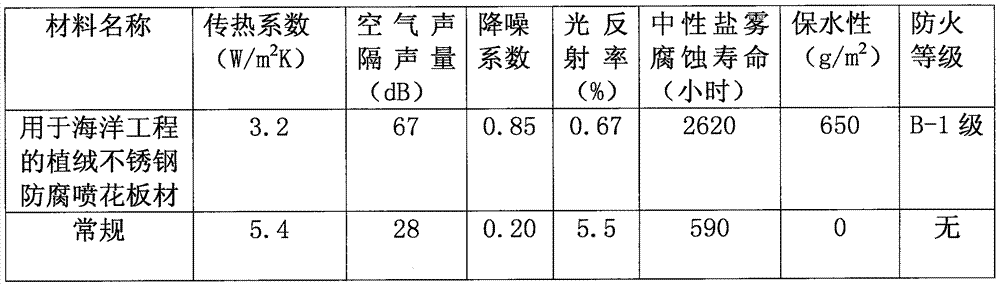

A technology of stainless steel plate and marine engineering, which is applied in the direction of surface coating liquid device, coating, pretreatment surface, etc., which can solve the problem of corrosion resistance, erosion resistance, humidity and heat resistance, which cannot adapt to harsh marine climate environment , The flocking stainless steel plate cannot achieve the light diffuse reflection effect, the flocking stainless steel plate does not have a strong velvet feeling, etc., to achieve the effect of ensuring the bonding strength and oxidation resistance, excellent light diffuse reflection effect, and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The present invention is used for the manufacture method of the flocking stainless steel flower-spray plate of marine engineering and comprises the following steps:

[0022] (1) Material selection: The material is a stainless steel plate with a thickness of 0.12mm and a width of 500mm;

[0023] (2), dip coating anticorrosion solution: the ratio is: Al-Zn-Si-Mg-Cu-RE-Ti alloy powder: glycerol: deionized water: water-based tackifying resin: isothiazolinone corrosion inhibition Agent: polysiloxane dipropylene glycol monomethyl ether: modified polyamide wax powder = 10g: 20mL: 20mL: 2g: 4g: 1mL: 1g, weigh the quantitative isothiazolinone corrosion inhibitor according to the above formula, dissolve into a certain amount of deionized water, then add water-based tackifying resin, polysiloxane dipropylene glycol monomethyl ether, glycerol, stir to dissolve, and slowly add Al-Zn-Si-Mg-Cu-RE under stirring -Ti alloy powder, then add modified polyamide wax powder, stir, and prepa...

Embodiment 2

[0037] The present invention is used for the manufacture method of the flocking stainless steel flower-spray plate of marine engineering and comprises the following steps:

[0038] (1) Material selection: The material is a stainless steel plate with a thickness of 2.5mm and a width of 3500mm;

[0039] (2), dip coating anticorrosion solution: the ratio is: Al-Zn-Si-Mg-Cu-RE-Ti alloy powder: glycerol: deionized water: water-based tackifying resin: isothiazolinone corrosion inhibition Agent: polysiloxane dipropylene glycol monomethyl ether: modified polyamide wax powder = 20g: 30mL: 35mL: 4g: 6g: 3mL: 3g, weigh the quantitative isothiazolinone corrosion inhibitor according to the above formula, dissolve into a certain amount of deionized water, then add water-based tackifying resin, polysiloxane dipropylene glycol monomethyl ether, glycerol, stir to dissolve, and slowly add Al-Zn-Si-Mg-Cu-RE under stirring -Ti alloy powder, then add modified polyamide wax powder, stir, and prepa...

Embodiment 3

[0051] The present invention is used for the manufacture method of the flocking stainless steel flower-spray plate of marine engineering and comprises the following steps:

[0052] (1) Material selection: the material is a stainless steel plate with a thickness of 1.5mm and a width of 2500mm;

[0053] (2), dip coating anticorrosion solution: the ratio is: Al-Zn-Si-Mg-Cu-RE-Ti alloy powder: glycerol: deionized water: water-based tackifying resin: isothiazolinone corrosion inhibition Agent: polysiloxane dipropylene glycol monomethyl ether: modified polyamide wax powder = 15g: 25mL: 30mL: 3g: 5g: 2mL: 2g, take quantitative isothiazolinone corrosion inhibitors according to the above formula, dissolve into a certain amount of deionized water, then add water-based tackifying resin, polysiloxane dipropylene glycol monomethyl ether, glycerol, stir to dissolve, and slowly add Al-Zn-Si-Mg-Cu-RE under stirring -Ti alloy powder, then add modified polyamide wax powder, stir, and prepare a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com