Method for observing expansion procedures of soil mass shear bands in confining pressure states

A technology of expansion process and shear band, applied in the field of geotechnical engineering, can solve problems such as inability to provide confining pressure, poor operability, and inability to analyze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

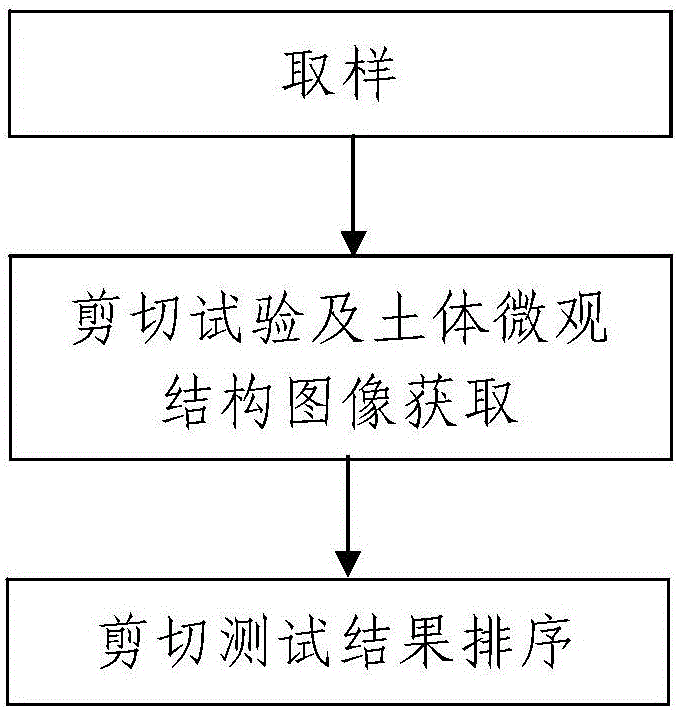

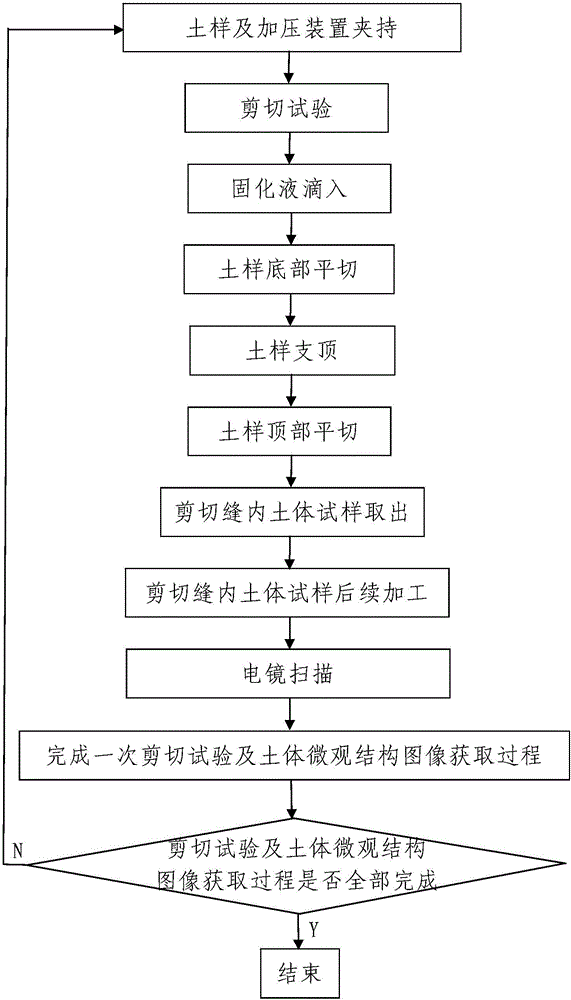

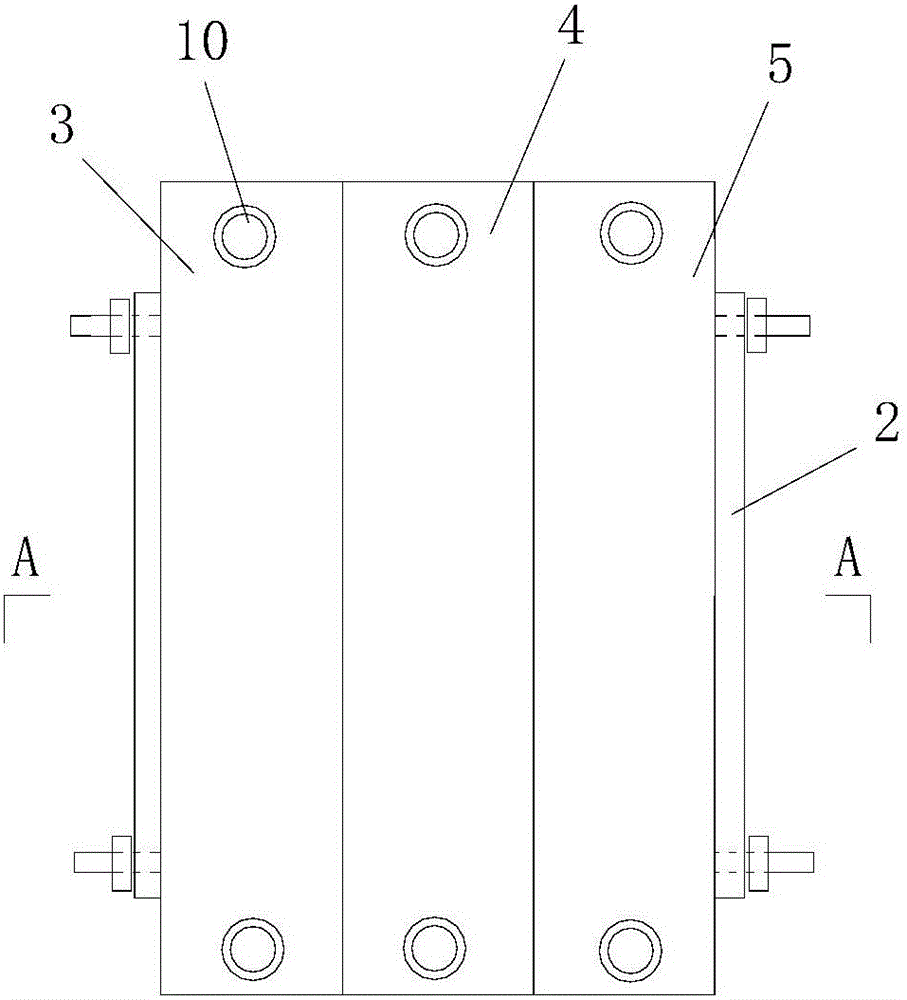

Method used

Image

Examples

Embodiment 2

[0215] In this example, the difference from Example 1 is that the curing solution described in step 203 is uniformly composed of epoxy resin, acetone, ethylenediamine and dibutyl phthalate in a volume ratio of 100:170:6:2.2 mixed.

[0216] In this embodiment, the remaining method steps are the same as those in Embodiment 1.

Embodiment 3

[0218] In this example, the difference from Example 1 is that the curing solution described in step 203 is uniformly composed of epoxy resin, acetone, ethylenediamine and dibutyl phthalate in a volume ratio of 100:170:8:1.8 mixed.

[0219] In this embodiment, the remaining method steps are the same as those in Embodiment 1.

Embodiment 4

[0221] In this example, the difference from Example 1 is that the curing solution described in step 203 is uniformly composed of epoxy resin, acetone, ethylenediamine and dibutyl phthalate in a volume ratio of 100:130:8:1.8 mixed.

[0222] In this embodiment, the remaining method steps are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com