Double-excitation solenoid type particle sensitive detection device adopting full-band filtering

A technology of detection equipment and solenoid, applied in the field of hydraulic equipment, can solve the problems of weak detection ability of sensor coils, inability to monitor early wear of parts, measurement errors, etc., to reduce the requirements of subsequent signal processing circuits and ensure effectiveness and consistency performance, sensitivity enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

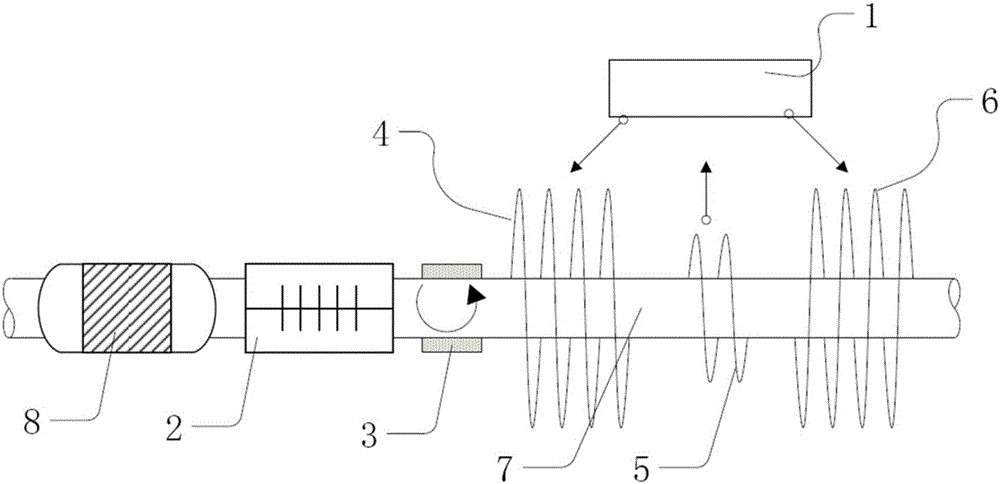

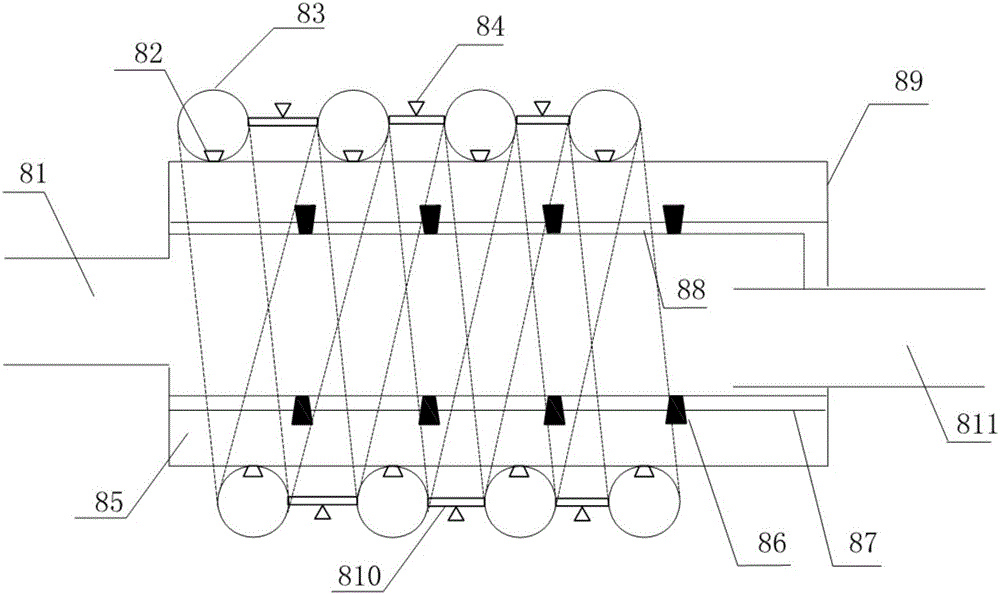

[0041] Please refer to the attached figure 1 To attach Figure 16 As shown, the present invention is a dual-excitation solenoid particle sensitive detection device using full-band filtering, which is arranged on a hydraulic pipeline 7, and consists of a filter 8, a separation and adsorption module 2, a rotary shaping module 3, Excitation coil I4, induction coil 5, excitation coil II6 and ECU1 are composed of several parts.

[0042] Wherein, the filter 8 , the separation and adsorption module 2 , the rotational shaping module 3 , the excitation coil I4 , the induction coil 5 , and the excitation coil II6 are sequentially arranged on the hydraulic pipeline 7 . The ECU1 is electrically connected to and controls the filter 8 , the separation and adsorption module 2 , the rotational shaping module 3 , the excitation coil I4 , the excitation coil II5 and the induction coil 5 .

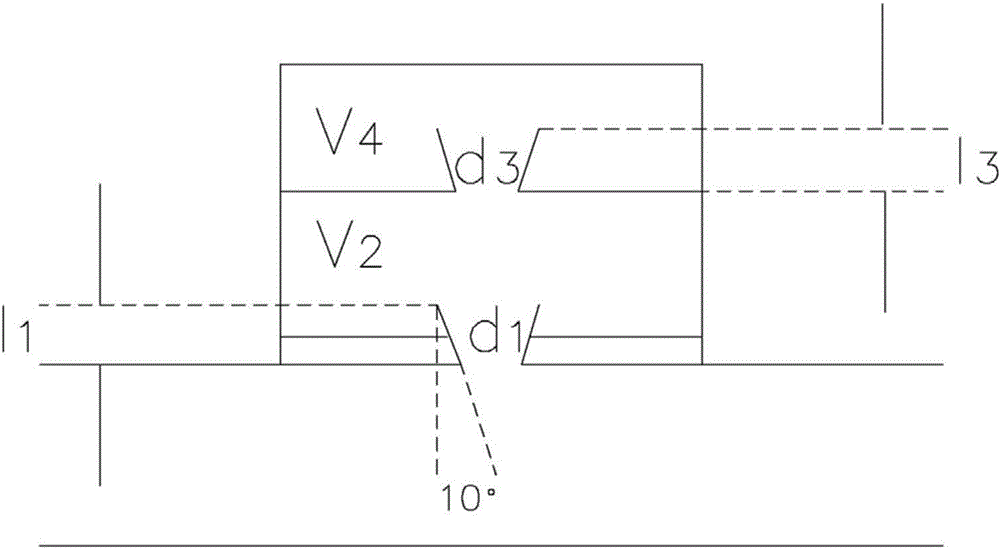

[0043] As the oil flow rate has a great influence on the detection characteristics, the detection sensi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com