Novel positive electrode material of lithium ion battery and preparation method of positive electrode material

A technology for lithium-ion batteries and positive electrode materials, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of destroying the stability of layered structures and the impact of nickel-cobalt-manganese ternary materials on charge and discharge performance, and achieve good cycle performance , avoid material damage, avoid the effect of structure damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

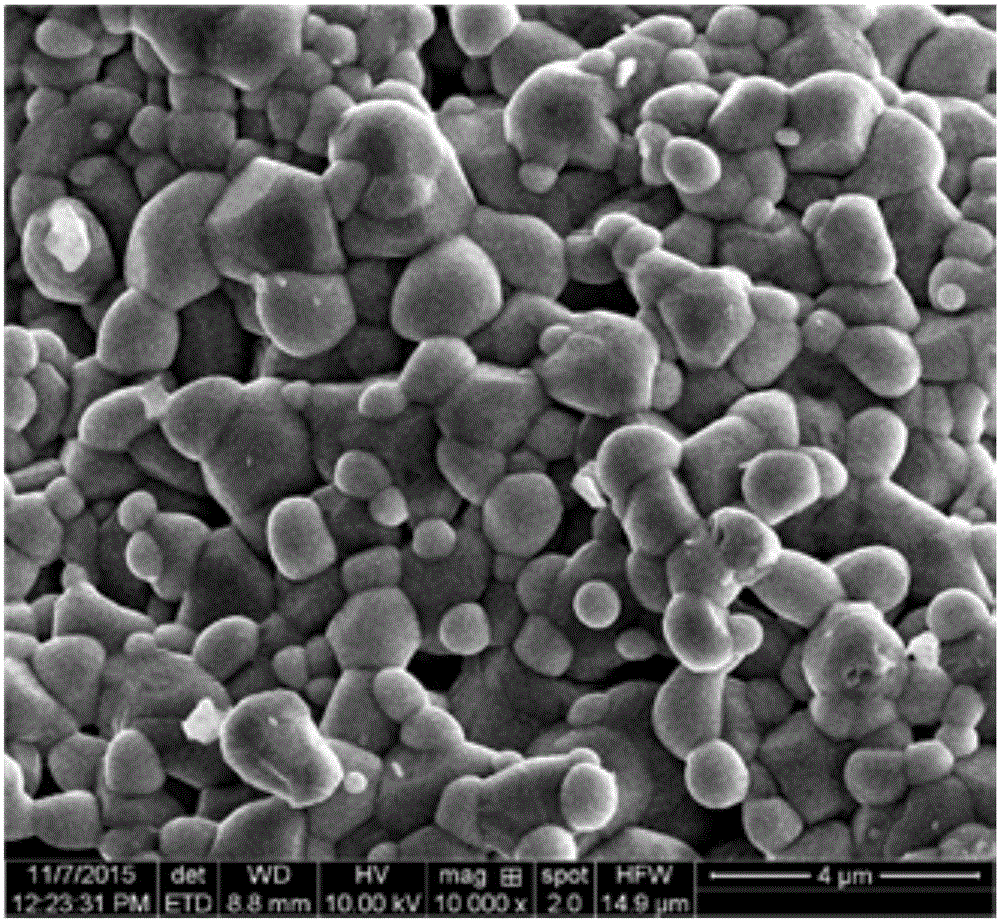

[0029] Dissolve nickel acetate, cobalt acetate, cerium nitrate, and lithium nitrate into a 0.5mol / L aqueous solution in a molar ratio of 0.5:0.2:0.3:1.1, and add 0.5mol / L citric acid dropwise during stirring into the prepared aqueous solution, and adjust the pH to 3.0 to form a sol. Then, the reaction was continuously stirred at 60° C. for 12 h to form a gel. The gel was dried at 120°C for 2 hours, and then placed in a sintering furnace for sintering at 900°C for 6 hours. The sintered material was ground and passed through a 300-mesh sieve to obtain a new lithium battery cathode material of Ni, Co, and Ce. Such as figure 1 As shown, the agglomerated particles formed by the agglomeration of the primary single crystal particles of the obtained positive electrode material have a particle size of about 3 μm. The cycle retention rate of the lithium ion battery prepared by using the positive electrode material at 0.1C4.25V normal temperature for 100 cycles is 93%.

Embodiment 2

[0031] Dissolve nickel acetate, cobalt acetate, molybdenum nitrate, and lithium hydroxide into a 0.05mol / L aqueous solution with a molar ratio of 0.8:0.1:0.1:1.08, and add 0.05mol / L tartaric acid dropwise during stirring into the prepared aqueous solution, and adjust the pH to 2.5 to form a sol. Then, the reaction was continuously stirred at 80° C. for 8 h to form a gel. The gel was dried at 150°C for 1 hour, and then placed in a sintering furnace for sintering at 930°C for 7 hours. The sintered material was ground and passed through a 300-mesh sieve to obtain a new lithium battery cathode material of Ni, Co, and Mo. The agglomerated particles formed by the agglomeration of the primary single crystal particles of the positive electrode material have a particle size of about 4 μm. The cycle retention rate of the lithium ion battery prepared by using the positive electrode material at 0.1C4.25V normal temperature for 100 cycles is 92%.

Embodiment 3

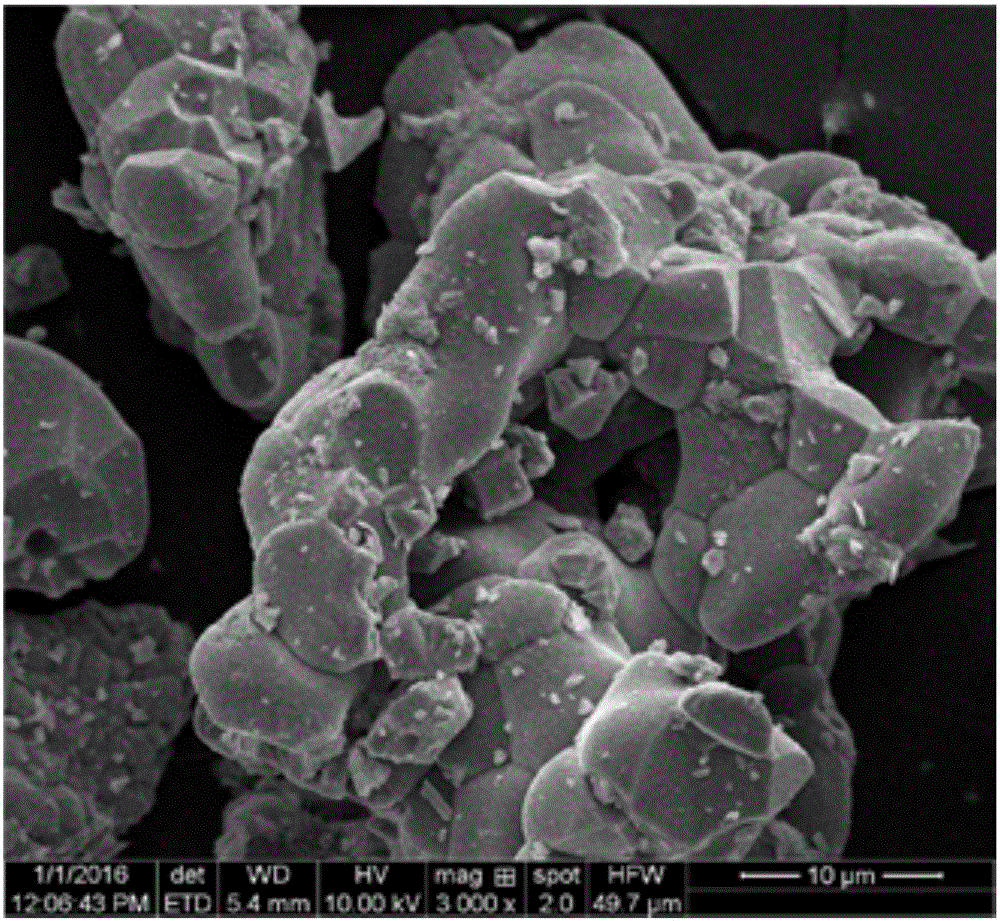

[0033] Dissolve nickel nitrate, cobalt nitrate, titanium nitrate, and lithium acetate into a 1.5mol / L aqueous solution in a molar ratio of 0.3:0.4:0.3:1.06, and add 1.5mol / L maleic acid dropwise during stirring Add it to the prepared aqueous solution, and adjust the pH to 2 to form a sol. Then the reaction was stirred continuously at 70°C for 10 h to form a gel. The gel was dried at 100°C for 4 hours, and then placed in a sintering furnace for sintering at 950°C for 6 hours. The sintered material was ground and passed through a 300-mesh sieve to obtain a new lithium battery cathode material of Ni, Co, and Ti. The agglomerated particles formed by the agglomeration of the primary single crystal particles of the positive electrode material have a particle size of about 8 μm. The cycle retention rate of the lithium ion battery prepared by using the positive electrode material at 0.1C4.25V normal temperature for 100 cycles is 91%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com