A method of preparing animal protein feed from potato dregs through fermentation and the feed prepared by the method

A potato residue and feed technology, applied in animal feed, animal feed, bacteria used in food preparation, etc., to achieve the effects of enhanced palatability, rich nutrients, and long shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Fermentation treatment of 30 tons of sweet potato dregs. The basic components of fresh sweet potato dregs are: crude protein 0.68%, crude fat 0.15%, ash content 0.67, crude fiber 29.3%, starch 44.7%, water content 70%. The implementation process is as follows.

[0053] (1) Candida utilis, Bacillus subtilis and Lactobacillus plantarum were activated on a slant, the culture temperature was 28°C, 31°C and 35°C respectively, and the time was 48 hours. At this time, the microbe count reached 10 9 cfu / g to obtain pure strains. Inoculate the obtained pure Candida utilis and Bacillus subtilis strains into a 1000mL Erlenmeyer shaker flask, control the culture temperature at 28-31°C, and the rotation speed is 150r / min, and cultivate for 24 hours to obtain the bacterial agent; saccharify 1kg corn paste After sterilization, the activated Lactobacillus plantarum was inserted, and cultured anaerobically at 37° C. for 48 hours to obtain the Lactobacillus plantarum inoculum. Inocula...

Embodiment 2

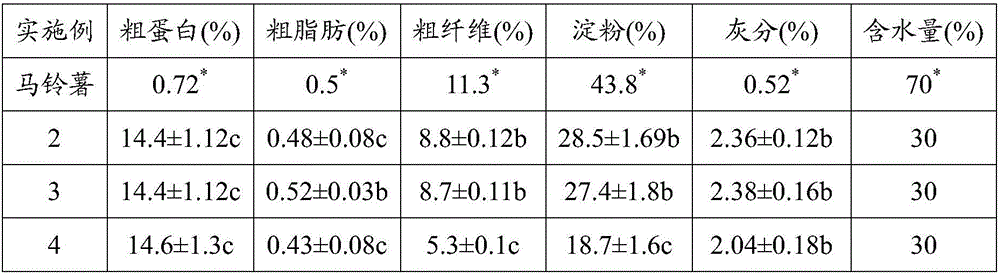

[0058] Fermentation treatment of 30 tons of potato residues. The basic components of fresh potato residue are: 0.72% crude protein, 0.50% crude fat, 0.52% ash, 11.3% crude fiber, 43.8% starch and 70% water content. The implementation process is as follows.

[0059](1) Candida utilis, Bacillus subtilis and Lactobacillus plantarum were activated on a slope, cultured at 28° C., 31° C. and 35° C. for 48 hours to obtain pure strains. Inoculate the obtained pure Candida utilis and Bacillus subtilis strains into a 1000mL Erlenmeyer shaker flask, control the culture temperature at 28-31°C, and the rotation speed is 150r / min, and cultivate for 24 hours to obtain the bacterial agent; saccharify 1kg corn paste After sterilization, the activated Lactobacillus plantarum was inserted, and cultured anaerobically at 37° C. for 48 hours to obtain the Lactobacillus plantarum inoculum. Inoculate the obtained various bacterial agents into the seed tank according to the inoculum amount of 10%, a...

Embodiment 3

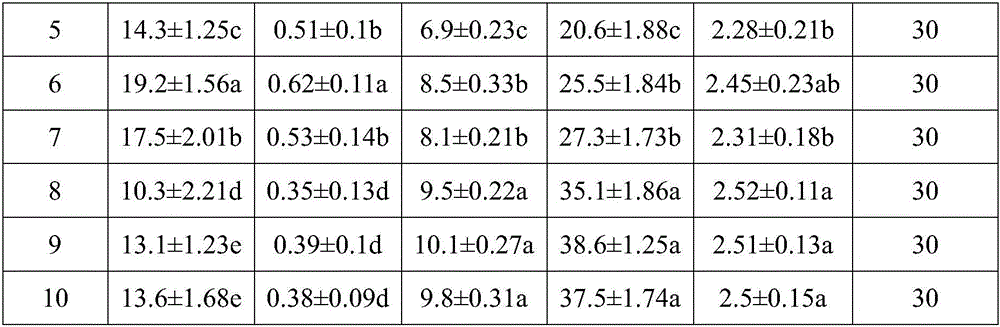

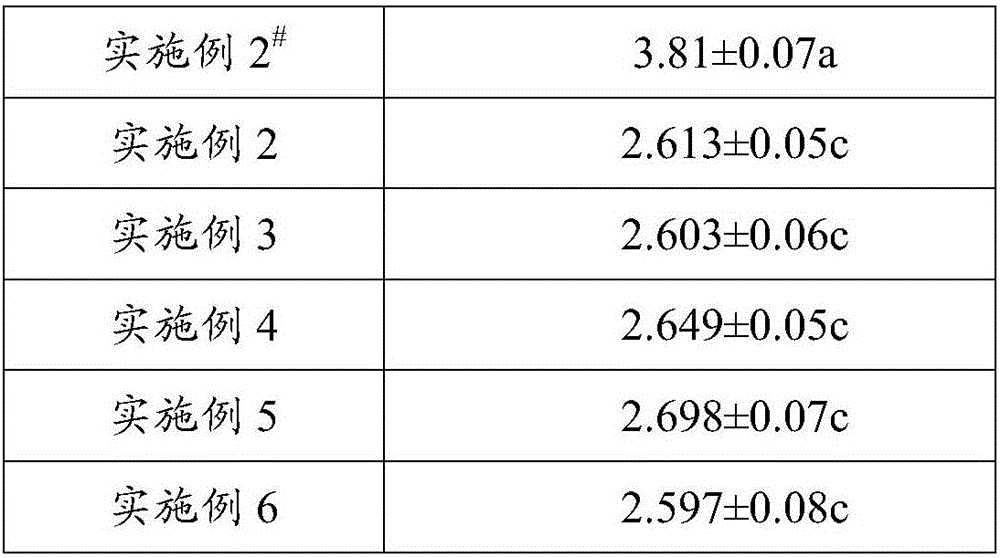

[0064] Example 3 was carried out in substantially the same manner as in Example 2, except that when inoculating in the bran medium in step (2), the water content was adjusted to 40%. The content of various components of the potato dregs before fermentation is no longer measured, but the content of various components after fermentation is measured. The results are shown in Table 1 and Table 2 below. In addition, the control group of Example 2 was used as a control for the feed-to-meat ratio, and no other control group was set up. The results are shown in Table 3 and Table 4 below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com