Method for separating toluene-ethylene glycol mixture by continuous azeotropic distillation

A technology of azeotropic rectification and mixture, which is applied in the field of separation of toluene-ethylene glycol mixture, can solve the problems of loss of entrainer, increase of energy consumption, reduction of the content of entrainer, etc., achieve simple equipment, reduce energy consumption, The effect of small operation difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

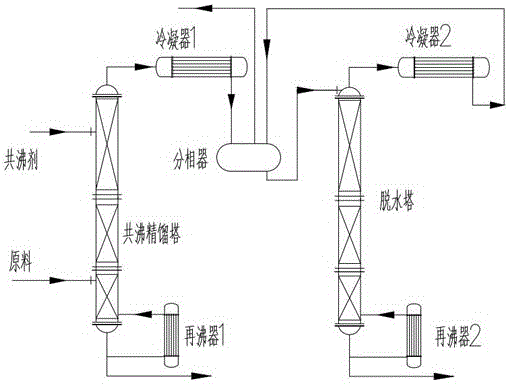

Image

Examples

Embodiment 1

[0020] A method for continuous azeotropic distillation and separation of toluene-ethylene glycol mixture, the amount of entrainer used is 250kg / h; the raw material processing capacity is 1000kg / h, and the raw material composition is the azeotropic composition of toluene and ethylene glycol. The number of trays in the azeotropic rectification column is 30, the feed position of the entrainer is on the first tray, and the feed position of the raw material is on the 5 trays. Ethylene glycol with a content of ≥99.99% is extracted from the bottom of the azeotropic distillation tower, and the steam at the top of the tower enters the phase separation tank after condensation to obtain a toluene product with a content of ≥99.99%; the water phase containing a small amount of toluene enters the dehydration tower and enters the dehydration tower The first tray; the number of trays in the dehydration tower is 20, and the water produced from the tower kettle is almost pure water; the steam at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com