Preparation method and application of grease degrading bacterium community

A technology for degrading bacteria and oil, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, and oil/fat production. It can solve the problems of low efficiency of decomposing surfactants and the impact of microbial toxicity, and achieve low cost and high degradation efficiency. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

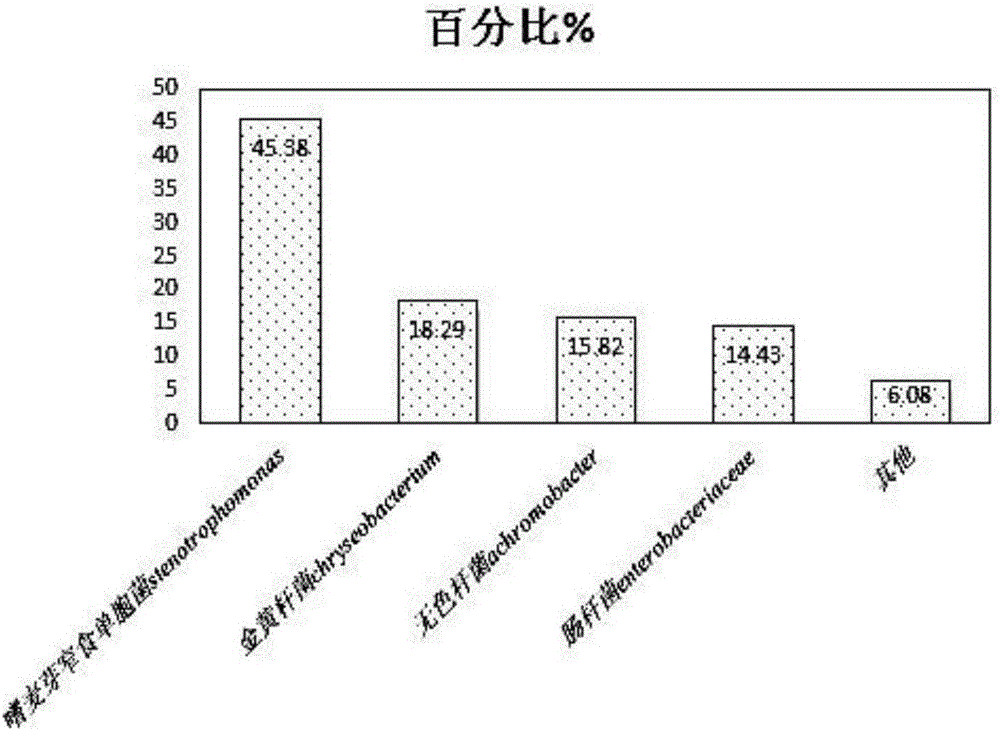

[0034] The preparation method of the grease-degrading flora of the present invention comprises the following specific steps:

[0035] (1) 65mg K 2 HPO 4 , 25.5mg KH 2 PO 4 , 133.8mg Na 2 HPO 4 12H 2 O, 500mg NH 4 Cl, 82.5mg CaCl 2, 67.5mg MgSO 4 ·7H 2 O, 0.75mg FeCl 3 ·6H 2 O was mixed with 1000mL deionized water; after adjusting the pH value to 7.0, sterilized at 121°C for 20min to obtain a liquid inorganic salt medium;

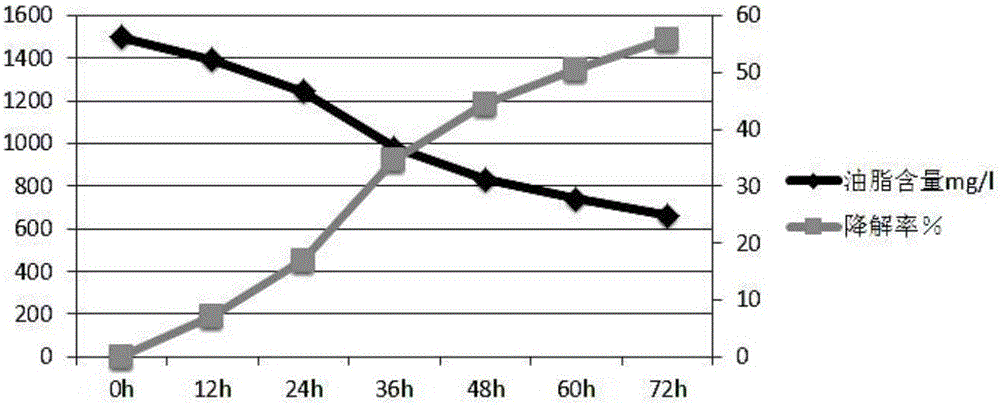

[0036] (2) Get 5g of the sediment sample collected from the kitchen swill waste grease wastewater area, add it to the aforementioned liquid inorganic salt culture medium, and then add the grease in the kitchen swill waste grease wastewater area accounting for 0.5% of the total volume; Then the mixture was placed in a constant temperature shaking box, and cultivated for 5 days at 30°C under stirring conditions with a rotation speed of 150r / min;

[0037] (3) Obtain a new liquid inorganic salt medium by the method described in step (1), get 10ml of...

Embodiment 1

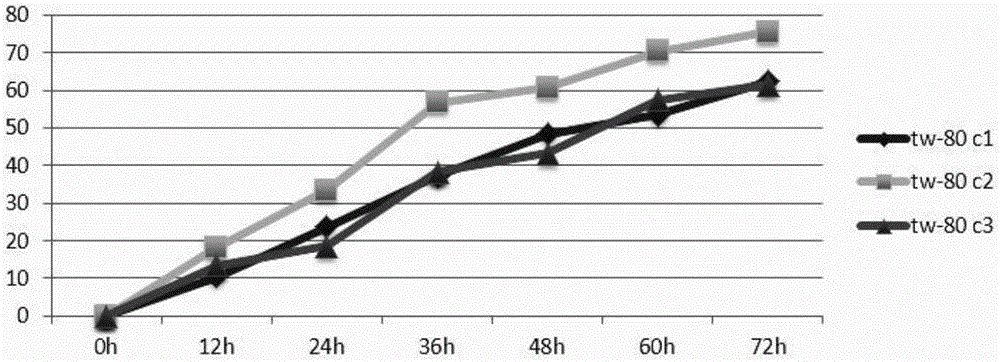

[0044] In this example, oil-degrading bacteria and surfactant Tw-80 (c 1 Concentration, c 2 Concentration, c 3 Concentration) work together to degrade the grease collected from the kitchen swill waste grease wastewater area, the specific steps are as follows:

[0045] Take 50mL of the liquid inorganic salt culture medium, take 2mL of the oil-degrading bacteria, and put them into a 100mL conical flask; Grease in the area; then add surfactant Tw-80 (c 1 Concentration, c 2 Concentration, c 3 Concentration) 1mL; placed in a constant temperature shaking box, maintained at a temperature of 30°C and a rotation speed of 150r / min for cultivation to degrade the grease content of the added kitchen slops in the grease wastewater area.

[0046] Set up the triangular flask according to the above steps, and divide it into three groups; the three groups of treatments correspond to adding different surfactants with different concentrations set in the following table, except that the added...

Embodiment 2

[0053] In this example, grease-degrading bacteria were used to work together with surfactants Tw-80, SDS, and saponin to degrade grease collected from the kitchen swill waste grease wastewater area. The specific steps are as follows:

[0054] Take 50mL of the liquid inorganic salt culture medium, take 2mL of the oil-degrading bacteria, and put them into a 100mL conical flask; Then add 1mL of surfactant; place in a constant temperature shaking box, keep the temperature at 30°C, and cultivate at a speed of 150r / min to degrade the oil content of the added kitchen slops in the oily wastewater area.

[0055] Set up the triangular flask according to the above steps, and divide it into three groups; the three groups of treatments correspondingly add different surfactants with different concentrations set in the following table, except that the added surfactants are different, and the rest of the conditions are the same:

[0056] Table 2 Tw-80, SDS, saponin experimental group design ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com