Low-carbon multi-element micro-alloyed multipurpose high-strength and high-toughness structural steel

A micro-alloying, high-strength and toughness technology, applied in the field of low-carbon multi-component micro-alloying multi-purpose high-strength and toughness structural steel, can solve the problems that the strength cannot meet the design requirements, can not fully meet the requirements, and the performance limitations of thick-walled parts, and achieve heat treatment. The effect of reliable performance, less risk of heat treatment process and low heat treatment cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

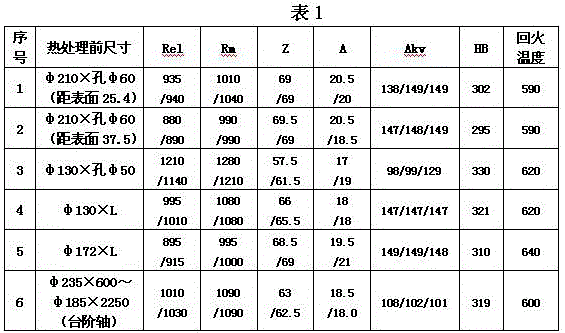

[0018] In this example, the mechanical properties of the parts processed from the low-carbon multi-element microalloyed multi-purpose high-strength and toughness structural steel of the present invention are shown in Table 1 after heat treatment:

[0019]

[0020] It can be seen from Table 1 that the performance characteristics of Gaofeng No. 2 steel quenched and tempered are:

[0021]

[0022] 1. Whether it is a 40-75 thick-walled part or a solid part with a diameter of 130-235, the performance of sampling at a distance of 25.4mm from the surface exceeds the requirements of API standards and industry standards, and reaches (yield strength 827-964MPa, resistance to Tensile strength 965-1033MPa, impact energy 90J) oilfield users special requirements, especially the performance of 75mm thick-walled parts at a depth of 37.5mm from the surface has also reached (yield strength 827-964MPa, tensile strength 965-1033MPa, impact energy 90J) high requirements. It fully shows that...

Embodiment 2

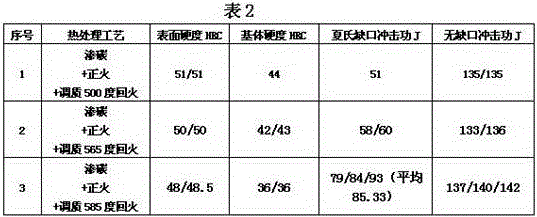

[0026] This example is to use the low-carbon multi-element microalloyed multi-purpose high-strength and toughness structural steel of the present invention to make mechanical jar slips. The performance data is shown in Table 2:

[0027]

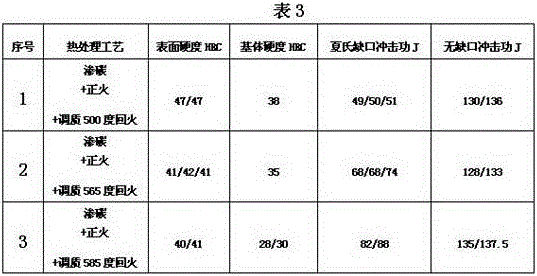

[0028] As a comparison, the performance data of the original technology using 35CrMo to manufacture the slips of the mechanical jar while drilling is shown in Table 3:

[0029]

[0030] It can be seen from Table 2 and Table 3 that when the slips made of 35CrMo are tempered at 500 degrees, the surface hardness is the same as that of foreign slips (47, 48HRC); because the core structure of slips made of 35CrMo has more non-martensite The transformation product, the impact energy is not high enough (49J), which is prone to brittle fracture. When the impact energy is increased by increasing the tempering temperature and sacrificing the surface hardness, the surface hardness at this time can no longer meet the wear resistance requirements, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com