Antibacterial viscose and preparation method thereof

A viscose fiber and berberine technology, applied in the textile field, can solve problems such as unfavorable human health, loss of antibacterial effect, uncomfortable close-fitting clothing, etc., and achieve the effect of maintaining excellent characteristics for a long time, improving taking performance, and good antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

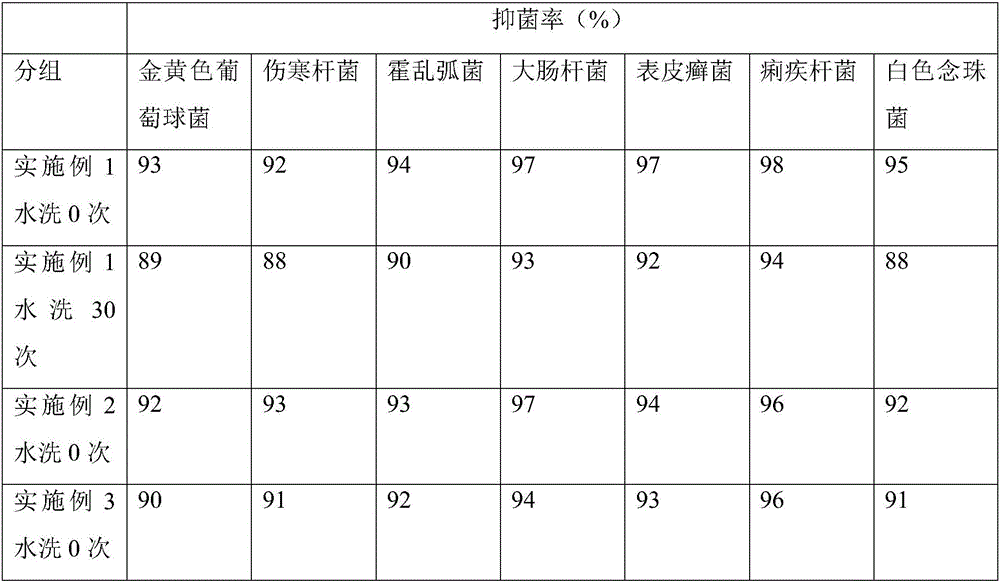

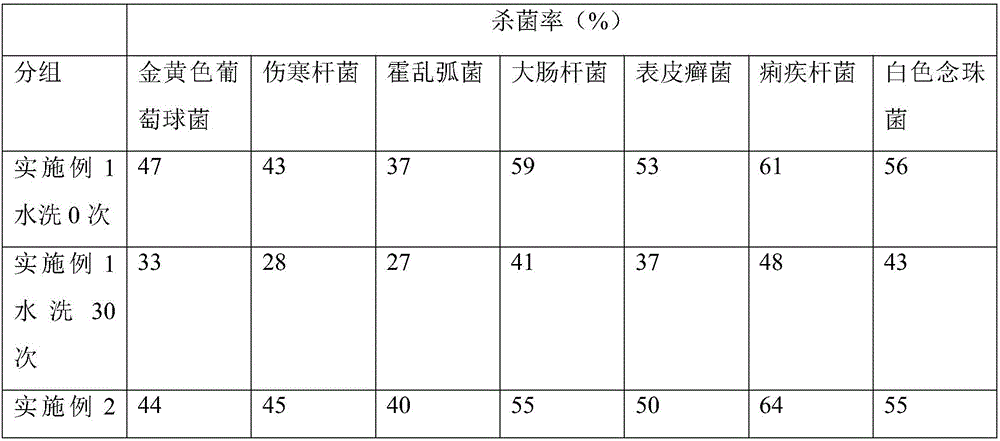

Embodiment 1

[0031] Prepare antibacterial viscose fiber 1, following steps:

[0032] Step 1: Grind 5 kg of Coptidis rhizoma into powder, add 30 kg of aqueous ethanol solution with a mass fraction of 55%, conduct ultrasonic extraction for 1.5 hours at a temperature of 80°C, the ultrasonic frequency is 28KHZ, filter and take the filtrate to obtain the berberine extract, adjust with hydrochloric acid pH = 2, stirred, cooled to 8°C, left to stand for 20 hours, filtered to obtain crystals, recrystallized with water, filtered to obtain berberine, dried in a 50°C oven to obtain 38g of berberine, prepared from berberine Ultrafine powder with powder particles less than 5μm;

[0033] Step 2, weighing chitin and sodium alginate, respectively preparing ultrafine powders with powder particles less than 5 μm;

[0034] Step 3. Preparation of cotton linter viscose fiber spinning stock solution in the aging process: specifically, soluble cellulose sulfonic acid is prepared by cooking, soaking, pressing, p...

Embodiment 2

[0041] Prepare antibacterial viscose fiber 2, following steps:

[0042] Step 1: Grind 5 kg of Coptis Rhizoma into powder, add 35 kg of aqueous ethanol solution with a mass fraction of 40%, conduct ultrasonic extraction at a temperature of 70°C for 1 hour, and the ultrasonic frequency is 30KHZ, filter and take the filtrate to obtain the berberine extract, adjust with hydrochloric acid pH=1, stir, cool down to 0°C, let stand for 16 hours, filter to obtain crystals, recrystallize with water, filter to obtain berberine, place in a 60°C drying oven to dry, and obtain 19.3g of berberine. Prepare ultrafine powder with powder particles less than 5 μm;

[0043] Step 2, weighing chitin and sodium alginate, respectively preparing ultrafine powders with powder particles less than 5 μm;

[0044] Step 3. Preparation of cotton linter viscose fiber spinning stock solution in the aging process: specifically, soluble cellulose sulfonic acid is prepared by cooking, soaking, pressing, pulverizing,...

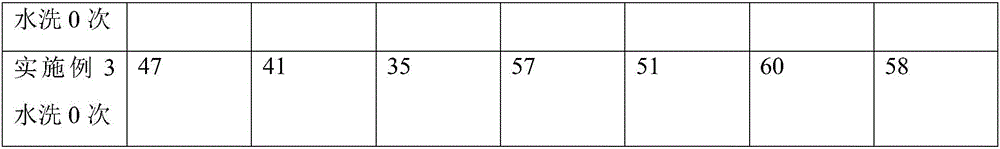

Embodiment 3

[0051] Prepare antibacterial viscose fiber 1, following steps:

[0052] Step 1: Grind 5 kg of Coptis Rhizoma into powder, add 40 kg of aqueous ethanol solution with a mass fraction of 70%, conduct ultrasonic extraction at a temperature of 75° C. for 2 hours, the ultrasonic frequency is 40 KHZ, filter the filtrate to obtain a berberine extract, adjust with hydrochloric acid pH=2, stirring, cooling to 10°C, standing for 14 hours, filtering to obtain crystals, recrystallizing with water, filtering to obtain berberine, and drying in a 50°C oven to obtain 21.6g of berberine. Prepare ultrafine powder with powder particles less than 5 μm;

[0053] Step 2, weighing chitin and sodium alginate, respectively preparing ultrafine powders with powder particles less than 5 μm;

[0054] Step 3. Preparation of cotton linter viscose fiber spinning stock solution in the aging process: specifically, soluble cellulose sulfonic acid is prepared by cooking, soaking, pressing, pulverizing, aging, ye...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com