Novel electric thermal storage system

A new type of electric heat storage technology, applied in the field of heat storage system, can solve the problems that the heat storage system cannot meet the user's free switching, the solid-liquid phase change material is expensive, and the iron oxide-based solid strength is poor, so as to save the laying cost, The effect of compact structure and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

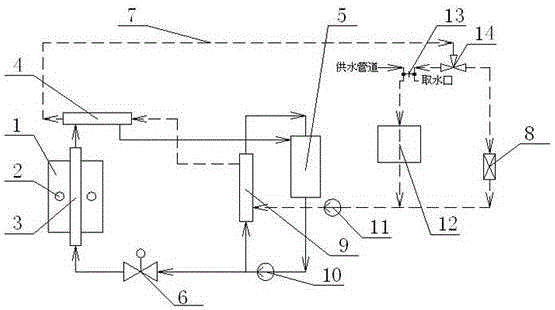

[0027] The main structure of this embodiment, such as figure 1 As shown, it includes a heat storage device 1, a heater 2, an internal circulation system and an external circulation system; the internal circulation system is connected with the heat collector 3, the A heat exchanger 4, the secondary The circulatory system is closed with the controller 6; the secondary circulatory system is formed by sequentially connecting the internal circulation pipeline to the liquid storage tank 5, the internal circulation water pump 10 and the B heat exchanger 9; the external circulatory system is indicated by a dotted arrow The external circulation pipeline of the A heat exchanger 4, the user system, the external circulation water pump 11 and the B heat exchanger 9 are closed in sequence; it is characterized in that: the user system includes a radiator 8 and a faucet 13; the faucet 13 is Single-handle double-valve combined faucet, the size and action of the two valves are exactly the same;...

Embodiment 2

[0031] This embodiment is further optimized on the basis of the above embodiments, further, as figure 1As shown, a water softening device 12 is installed on the side where the water tap 13 is connected to the valve of the water supply pipeline. The user uses, and when heating, because does not need to connect water source continuously, demineralized water device 12 will stop running because there is no water flow through. Other parts of this embodiment are the same as those of the foregoing embodiments, so details are not repeated here.

[0032] It can be understood that the structure of the electric heat storage system according to an embodiment of the present invention, such as the working principle and working process of components such as the radiator 8 and the B heat exchanger 9, are all prior art, and those skilled in the art It is well known, and will not be described in detail here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com