Preparation method for modified graphene

A graphene and modification technology, applied in the preparation of modified graphene, graphene materials and preparation fields, can solve the problems of unsatisfactory effect, difficult control and operation, complicated preparation process, etc., and achieves low cost, easy operation and low cost. The effect of simple control and preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

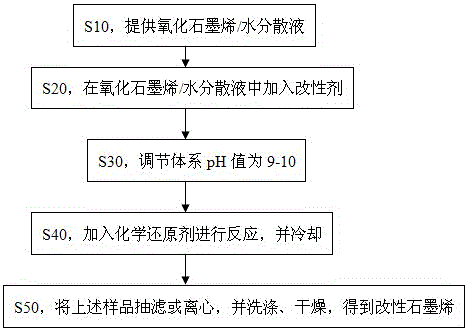

[0022] The preparation method of modified graphene of the present invention, preparation steps are as follows, please also refer to figure 1 ,

[0023] S10, dispersing graphene oxide in deionized water, stirring ultrasonically at room temperature for 0.5-16 hours, to obtain a graphene oxide / water dispersion with a concentration of 0.01-3.0 mg / mL;

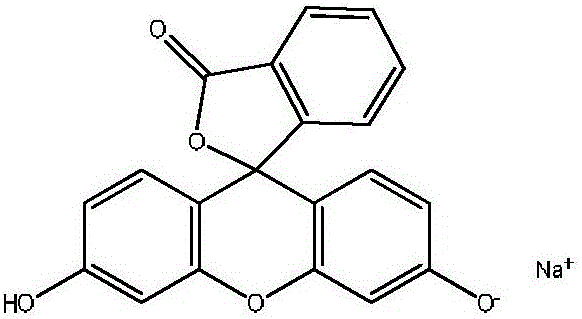

[0024] S20, adding the modifier sodium fluorescein to the above graphene oxide / water dispersion, and stirring at 20-60 degrees Celsius for 0.1-10 hours;

[0025] S30, add alkali solution to the system obtained in S20, stir for 0.1-10 hours, and adjust the pH value of the system to 9-10; the alkali solution is a sodium hydroxide solution with a concentration of 0.1-2.0mol / L or a mass concentration of 25%- 28% ammonia solution.

[0026] S40, add a chemical reducing agent, such as hydrazine hydrate, vitamin C or glucose, to the system obtained in S30, react at 60-95 degrees Celsius for 10-100 hours, and cool to room temperature;

[...

Embodiment 1

[0034] First, disperse graphene oxide in deionized water, and stir ultrasonically at room temperature for 1 hour to obtain a graphene oxide / water dispersion with a concentration of 0.05 mg / mL; then add a modifier, namely sodium fluorescein, and stir at 25 degrees Celsius for 2 hour; then add an aqueous sodium hydroxide solution with a concentration of 1.0 mol / L, stir for 0.5 hours, and adjust the pH value to 9-10; then add the chemical reducing agent hydrazine hydrate, and react at 80 degrees Celsius for 48 hours. Finally, the above sample was suction-filtered, washed with a large amount of ethanol and deionized water until it was nearly neutral or neutral, and dried at 50 degrees Celsius to a constant weight in an atmospheric environment to obtain modified graphene.

[0035] According to the mass ratio, graphene oxide: sodium fluorescein: chemical reducing agent is 1:5:10.

Embodiment 2

[0037] First, disperse graphene oxide in deionized water, and stir ultrasonically at room temperature for 3 hours to obtain a graphene oxide / water dispersion with a concentration of 0.1 mg / mL; then add a modifier, namely sodium fluorescein, and stir at 30 degrees Celsius for 2 hours; then add an aqueous sodium hydroxide solution with a concentration of 2.0 mol / L, stir for 3 hours, and adjust the pH value to 9-10; then add a chemical reducing agent vitamin C, and react at 90 degrees Celsius for 32 hours. Finally, the above sample was suction-filtered, washed with a large amount of ethanol and deionized water until it was nearly neutral or neutral, and dried at 60 degrees Celsius to a constant weight in an atmospheric environment to obtain modified graphene.

[0038] According to the mass ratio, graphene oxide: sodium fluorescein: chemical reducing agent is 1:10:20.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com