Water treatment method capable of regulating and controlling rapid start of nitrification effect of biological membrane

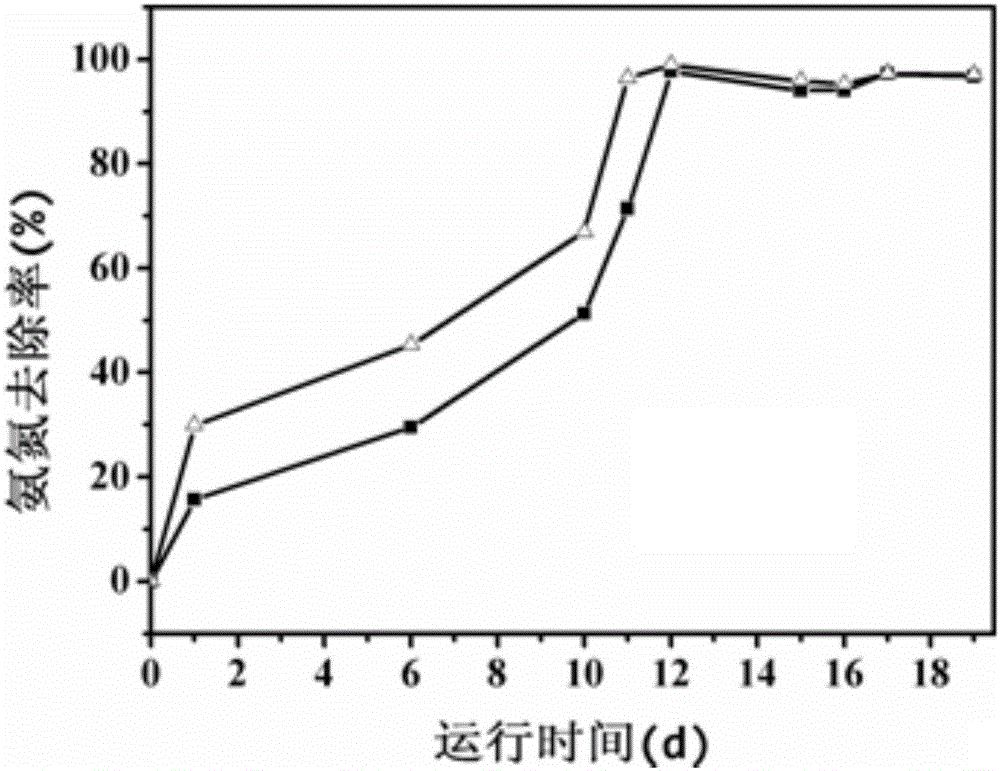

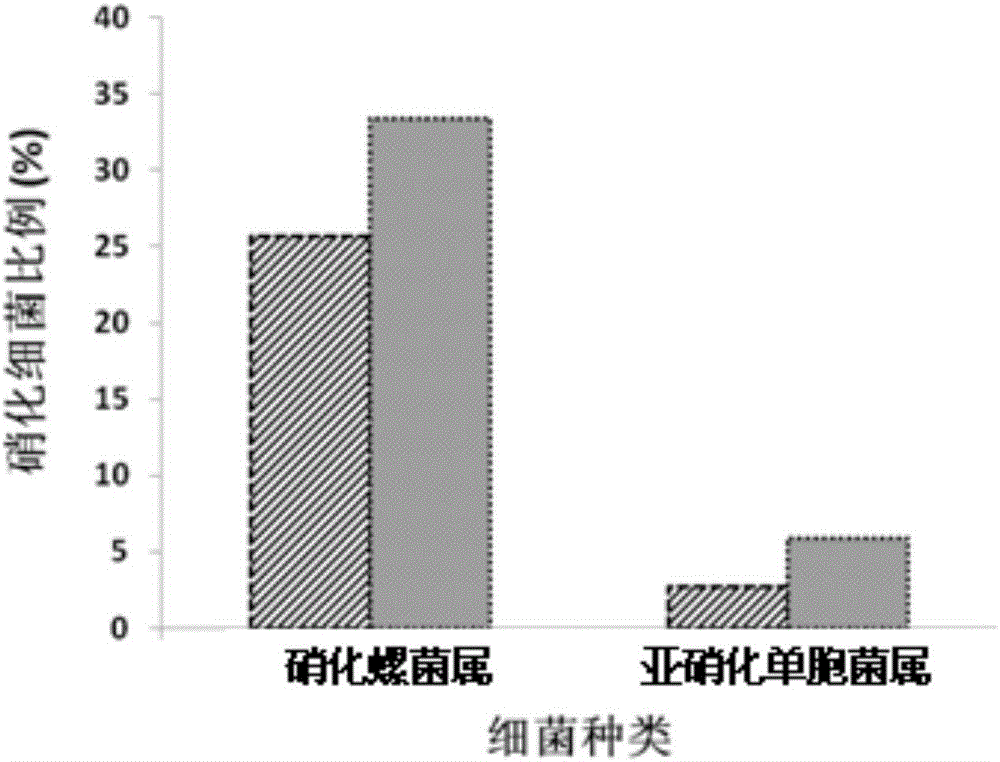

A nitrification, quick-start technology, applied in biological water/sewage treatment, sustainable biological treatment, chemical instruments and methods, etc., can solve the problem of long generation period of nitrifying bacteria, the influence of reactor operating efficiency, and the difficulty of biofilm on the surface of packing, etc. problems, to achieve the effect of promoting growth and nitrification, shortening the start-up period, and improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific implementation mode one: in this implementation mode, a water treatment method that regulates the rapid start of biofilm nitrification:

[0022] During the operation of the bioreactor, the hydraulic retention time is 0.5-2.5h, the dissolved oxygen concentration is higher than 2mg / L, the operating temperature of the bioreactor is 5-30°C, and the feed water treatment filler is a fluidized bed light suspension filler, of which biological The initial concentration of exogenous AHLs at the initial stage of reactor start-up is 0.1 μmol / L-1.0 μmol / L, and the method of adding the exogenous AHLs is directly adding to the bioreactor or loading exogenous AHLs on the surface of the carrier and then adding the carrier Dosing into the bioreactor, the concentration of ammonia nitrogen in the influent water is ≤5mg / L, and the concentration of total organic carbon is ≤10mg / L;

[0023] The exogenous AHLs are N-butyryl homoserine lactone (C 4 -HSL), N-hexanoyl homoserine lactone...

specific Embodiment approach 2

[0025] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the light suspension filler carrier of the fluidized bed is polyethylene plastic filler or polypropylene plastic filler. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0026] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that the dissolved oxygen concentration is 5-7 mg / L. Others are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com