Anti-mud small material for compounding of polycarboxylate superplasticizer and application method thereof

A technology of water reducer and polycarboxylate, which is applied in the field of chemical building materials, can solve the problems of poor use effect of polycarboxylate water reducer, influence on concrete durability, complicated process, etc., achieve reasonable formula components, low production cost, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of anti-mud type small material for polycarboxylate water reducer compounding, the raw materials are weighed according to the following mass percentage ratio: sodium pyrosulfite 60%, sodium hexametaphosphate 10%, sodium tripolyphosphate 15%, sodium nitrate 15% %, Mix all kinds of raw materials manually or with a mixer to prepare anti-mud agent 1#.

Embodiment 2

[0028] A kind of anti-mud type small material for polycarboxylate water reducer compounding. The raw materials are weighed according to the following mass percentage ratio: sodium pyrosulfite 70%, sodium tripolyphosphate 20%, sodium nitrate 10%, and various raw materials are manually Or use a mixer to mix evenly to prepare anti-mud agent 2#.

Embodiment 3

[0030] A kind of anti-mud small material for compounding polycarboxylate water reducing agent. The raw materials are weighed according to the following mass percentage ratio: sodium pyrosulfite 68%, sodium hexametaphosphate 10%, sodium tripolyphosphate 10%, sodium nitrate 12% %, mix various raw materials manually or with a mixer to prepare anti-mud agent 3#.

[0031] Illustrate the application effect of embodiment 1~3 below by concrete test:

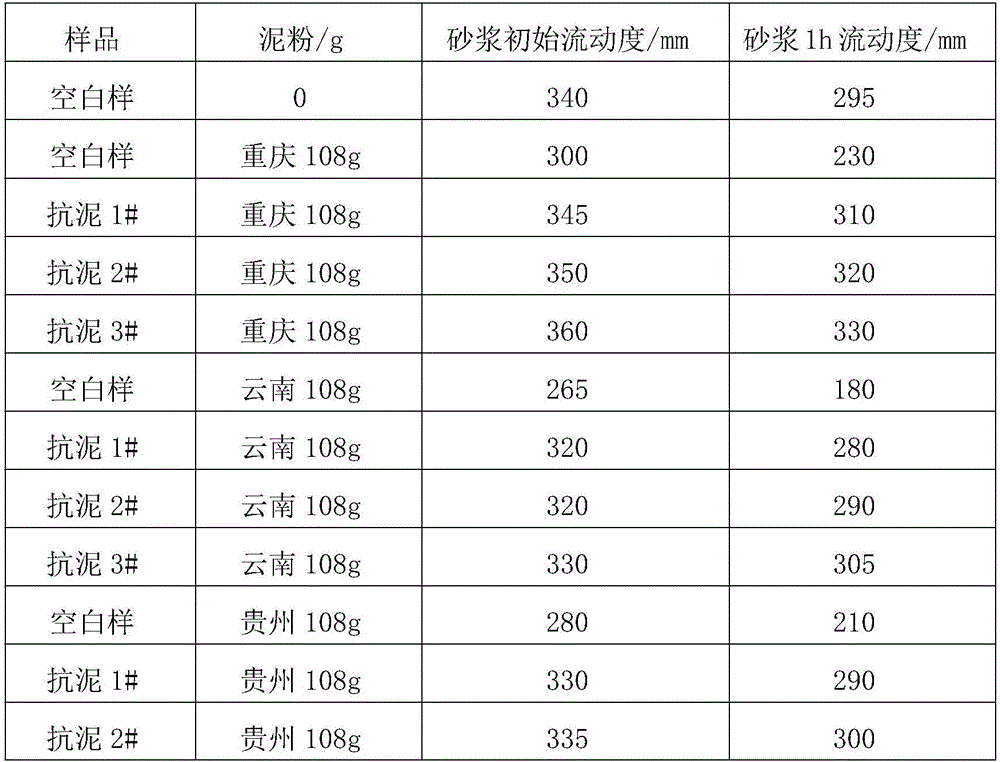

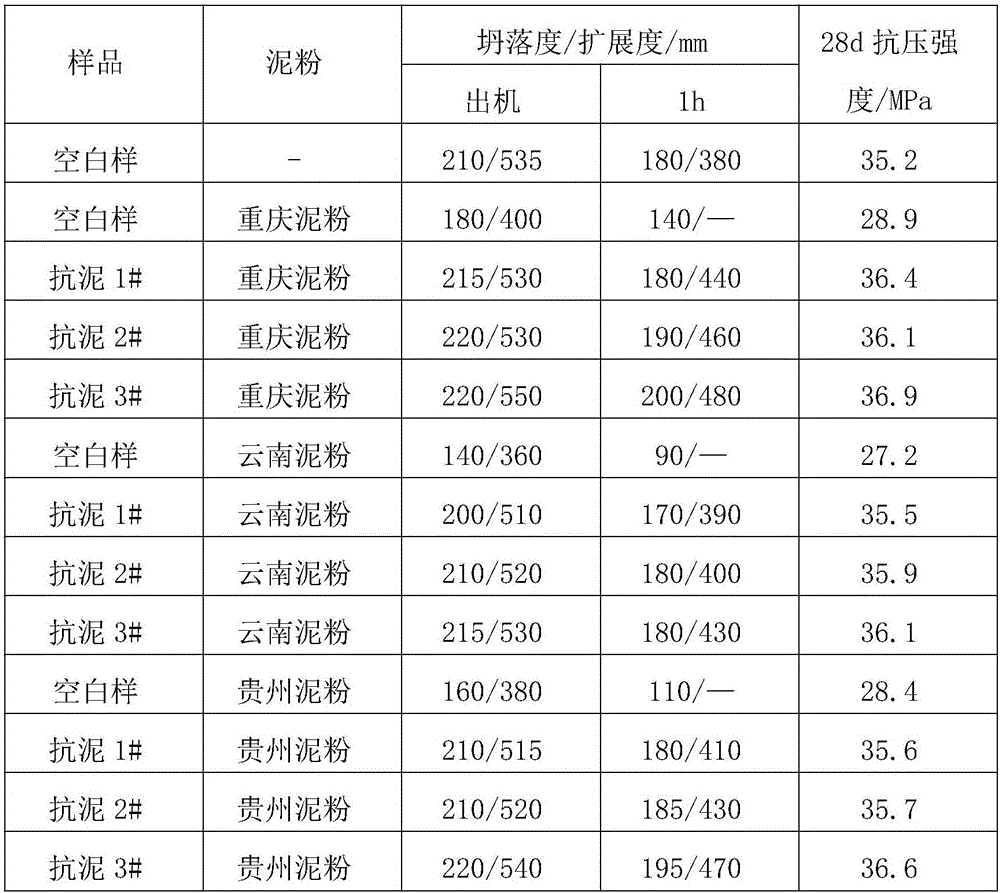

[0032] In order to ensure the diversity of clay samples and combine them with practical applications, mud samples were collected from the elutriation pools of sand fields in Yunnan, Guizhou, and Chongqing, and then dried and ground to make mud powder evenly.

[0033] (1) Fluidity test of mortar (refer to GB / T2419-2005 "Measurement Method for Fluidity of Cement Mortar Sand")

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com