Poly(p-phenylene vinylene) precursor, preparation method thereof and application of poly(p-phenylene vinylene) precursor to high-molecular fluorescent microspheres

A technology of phenylene vinylene and fluorescent microspheres, applied in the field of fluorescent sensing materials, can solve the problems of inability to satisfy fluorescent coding technology, single emission wavelength of fluorescent microspheres, complicated preparation method, etc. Stable, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

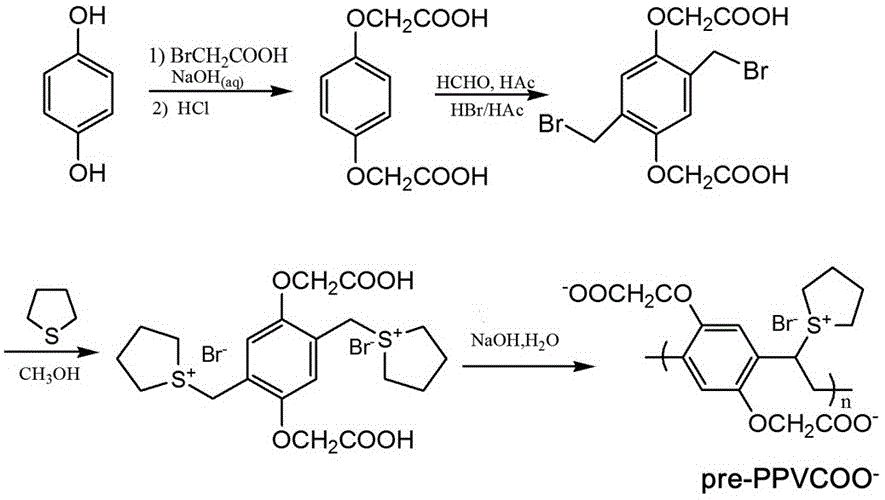

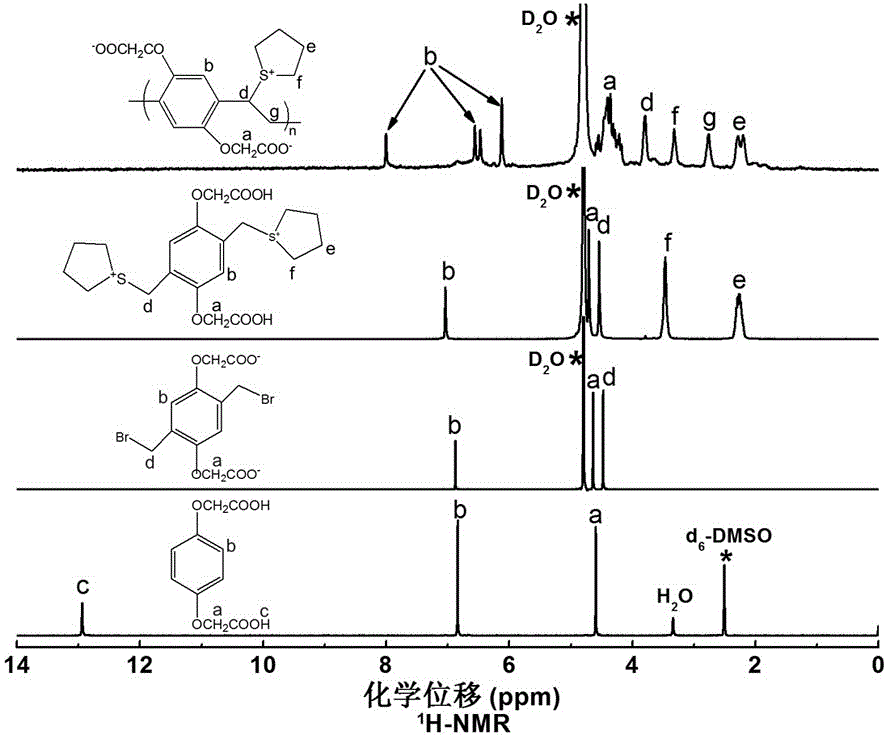

[0027] This example provides a method for preparing a poly(p-phenylenevinylene) precursor with a carboxyl group in the side group, see the attached figure 1 , which is a roadmap for the preparation of poly(p-phenylenevinylene) precursors with carboxyl groups in the side groups. Using hydroquinone as the starting material, replace the hydrogen on the phenolic hydroxyl group with bromoacetic acid to obtain p-phenoxydiacetic acid, introduce a bromomethyl group at the ortho position of the oxyacetic acid group on the benzene ring, and then use a thiophene group Substituting bromine to obtain polymer monomers, and finally preparing an aqueous solution of poly(p-phenylenevinylene) precursor with carboxyl groups in an alkaline aqueous environment, denoted as pre-PPVCOO - aqueous solution. Specific steps are as follows:

[0028] (1) Add sodium hydroxide (3.6 g) and deionized water (20 mL) into a two-neck flask, heat and stir to dissolve the sodium hydroxide completely, then add hydr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com