High-color-rendering-index high-thermal-conductivity fluorescent film, preparation method and application in display equipment

A technology with high CRI and high thermal conductivity, applied in semiconductor lasers, lasers, semiconductor devices, etc., can solve problems such as low color rendering index, difficulty in adjusting the size and shape of thin film materials, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

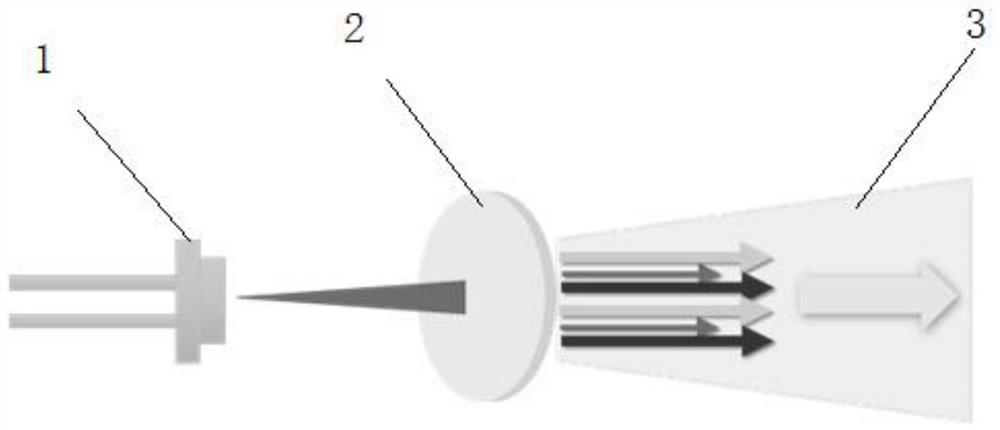

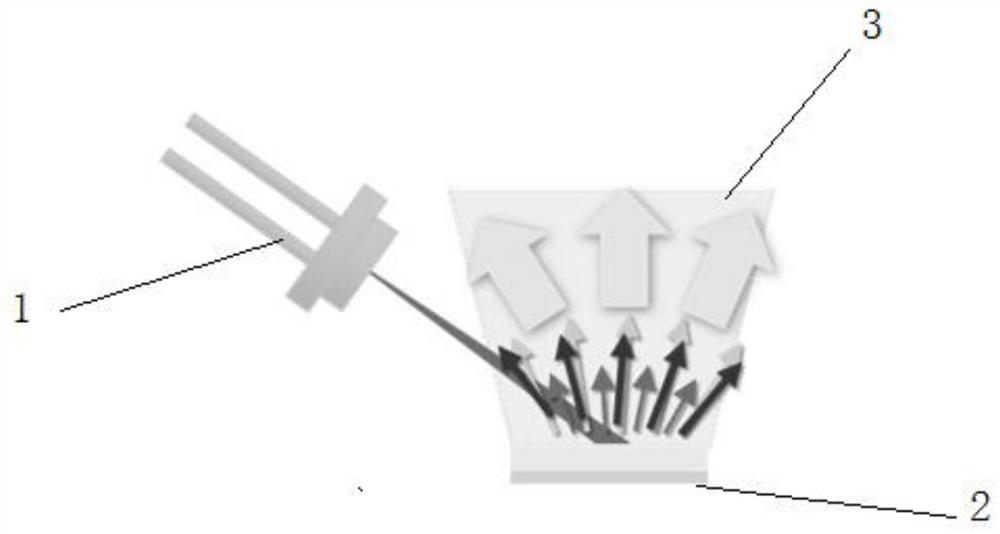

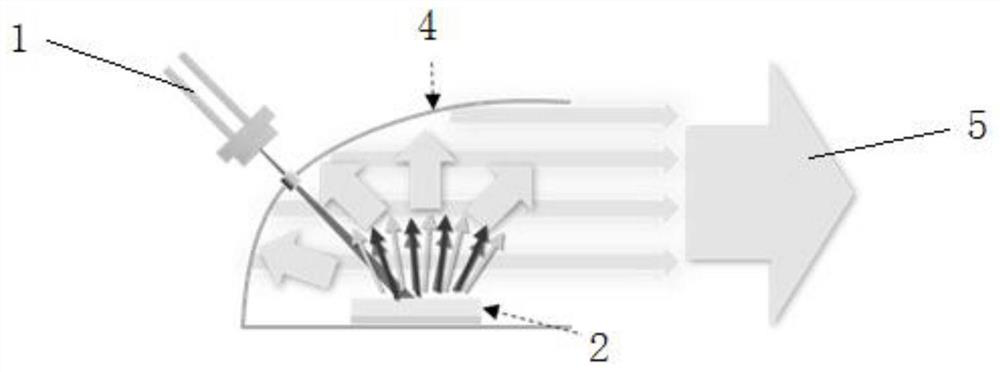

[0042] Application of high CRI and high thermal conductivity fluorescent film in laser display light source module (transmissive type);

[0043] (1) Mix YAG:Ce fluorescent powder with an emission wavelength of 565nm and silica gel, resin, and silicone resin composite glue in a mass ratio of 4:1 to prepare a mixed slurry;

[0044] (2) Using the screen printing process, the thickness of the screen is 0.06mm, and the above mixed slurry is brushed on the sapphire substrate coated with a yellow-green light reflection and blue light transmission film, and then dried at 300 ° C for 30 minutes;

[0045] (3) Carry out cross-sectional SEM test to fluorescent film, its result is as follows Figure 5 shown;

[0046] (4) The thermal conductivity test of the high thermal conductivity fluorescent film shows that its thermal conductivity is 29W / (m.k)@25℃;

[0047] (5) Encapsulate the prepared high CRI and high thermal conductivity fluorescent film with a 455nm blue laser diode in a transpar...

Embodiment 2

[0050] Application of high CRI and high thermal conductivity fluorescent film in green light source modules for laser display and LED display (transmissive type);

[0051] (1) GaYAG aluminate green fluorescent powder with an emission wavelength of 545nm is mixed with silica gel, resin, and silicone resin composite glue in a mass ratio of 4:1 to prepare a mixed slurry;

[0052] (2) Using the screen printing process, the thickness of the screen is 0.06mm, and the above mixed slurry is brushed on the sapphire substrate coated with a yellow-green light reflection and blue light transmission film, and then dried at 300 ° C for 30 minutes;

[0053] (3) Encapsulate the prepared high CRI and high thermal conductivity fluorescent film with the 455nm blue laser diode and the 460nm blue LED chip respectively in a transparent encapsulation mode;

[0054] (4) Spectrum tests are carried out on the packaged laser display and LED display light source modules, and the results are as follows ...

Embodiment 3

[0057] Application of high CRI and high thermal conductivity fluorescent film in red light source of laser display light source module (transmissive type);

[0058] (1) Mix the nitride red fluorescent powder with an emission wavelength of 630nm and silica gel, resin, and silicone resin composite glue in a mass ratio of 4:1 to prepare a mixed slurry;

[0059] (2) Using the screen printing process, the thickness of the screen is 0.06mm, and the above mixed slurry is brushed on the sapphire substrate coated with a yellow-green light reflection and blue light transmission film, and then dried at 300 ° C for 30 minutes;

[0060] (3) Encapsulate the prepared high CRI and high thermal conductivity fluorescent film with the 455nm blue laser diode and the 460nm blue LED chip respectively in a transparent encapsulation mode;

[0061] (4) Spectrum tests are carried out on the packaged laser display and LED display light source modules, and the results are as follows Figure 8 shown in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com