A kind of preparation method of fluorescent carbon quantum dot polymer hybrid material

A technology of carbon quantum dots and hybrid materials, which is applied in the field of preparation of fluorescent carbon quantum dot polymer hybrid materials, can solve problems such as complex operation process, achieve uniform size distribution, excellent fluorescence performance, and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1 Preparation of carbon quantum dots

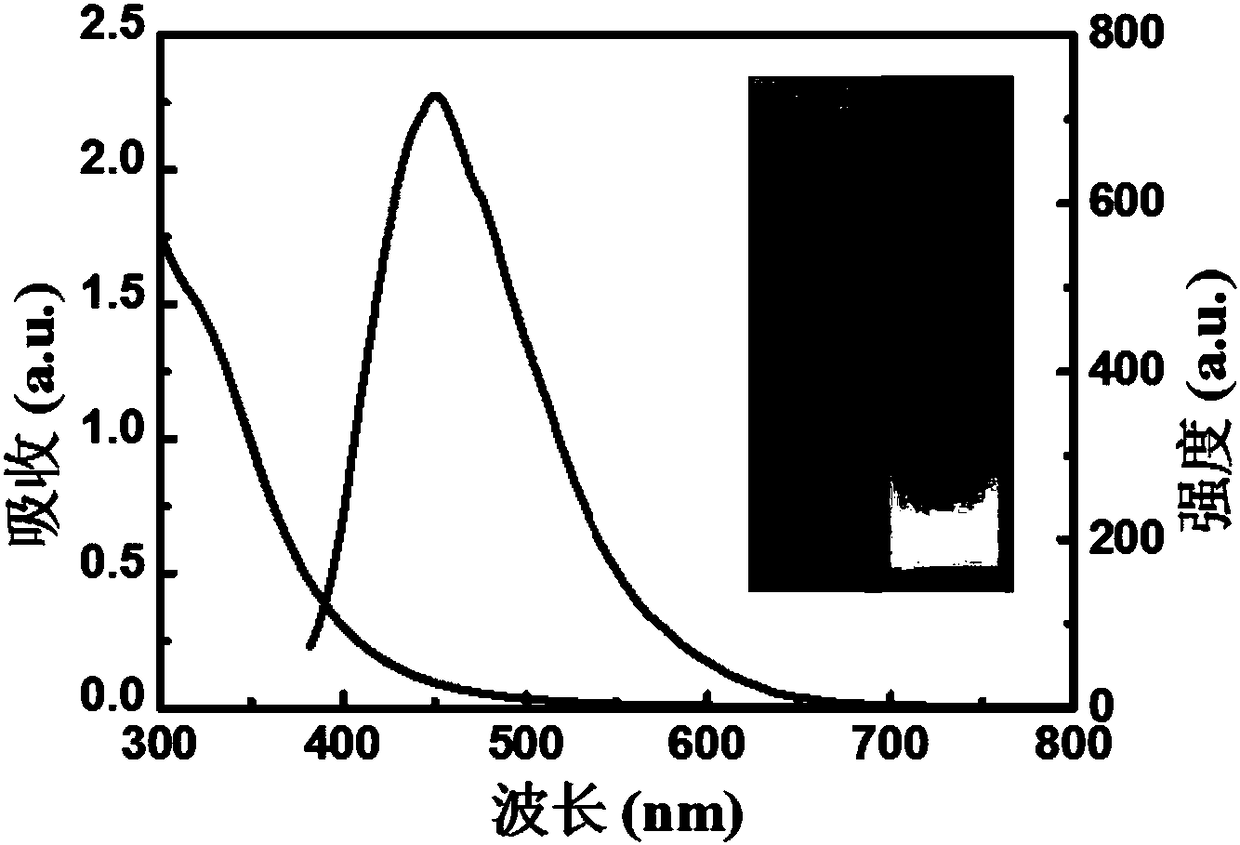

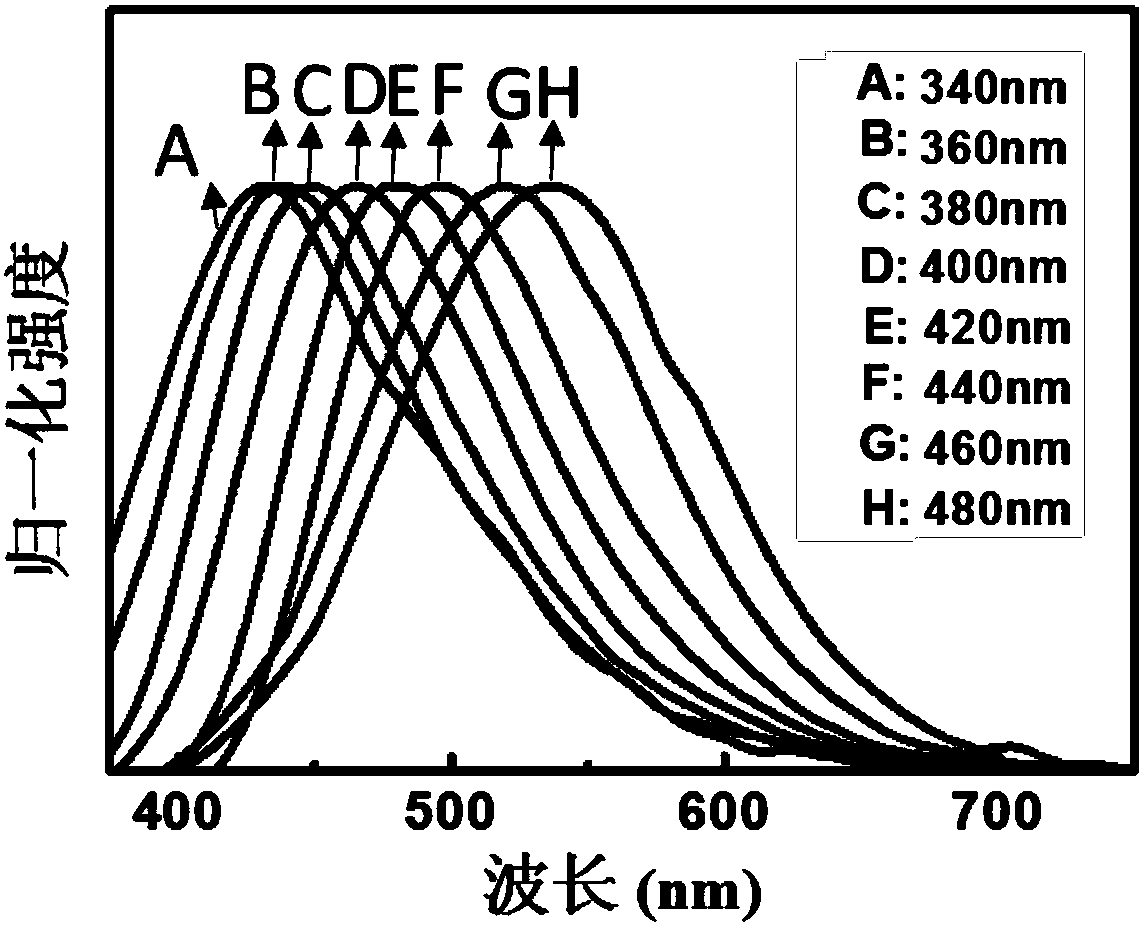

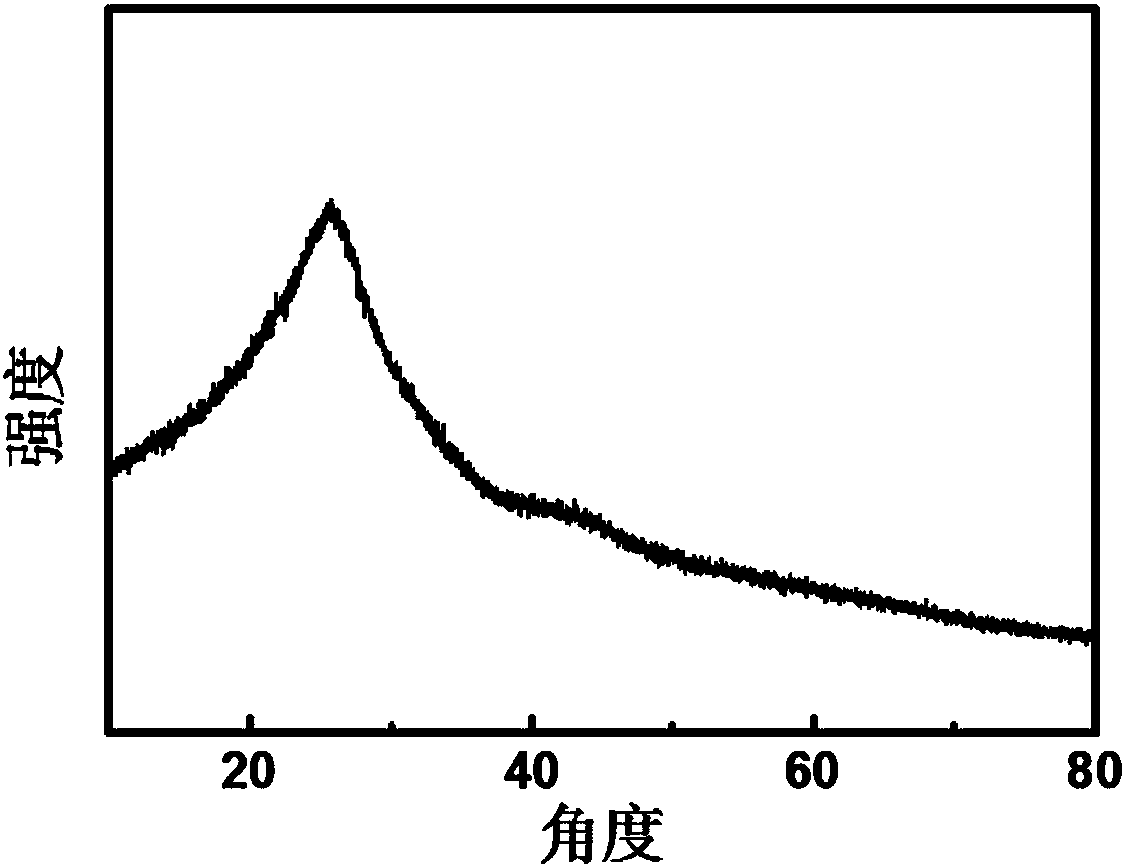

[0035] Take 5g of cleaned and dried pig small intestine and place it in a porcelain boat, then place the porcelain boat in a tubular quartz tube, pass nitrogen protection into the tube furnace, and raise the temperature to 250°C with a heating rate of 6°C / min , the processing time is 3h. After the reaction is finished, grind the obtained black solid into powder, take 1g of the solid and disperse it in 10mL aqueous solution, and use an ultrasonic cleaner with a power of 100w and a frequency of 40kHz for 60min to obtain a uniformly dispersed suspension. The solution was centrifuged at 12,000 rpm for 15 minutes to remove the black solid precipitate to obtain a clear liquid; the clear liquid was filtered with a 0.2 μm PES filter membrane to further remove insoluble impurities to obtain a filtrate. Measured by the fluorescence spectrometer, the main peak is at about 450nm, which is a typical blue fluorescence, and the ultraviolet absor...

Embodiment 2

[0039]Take 5g of cleaned and dried pig small intestine and place it in a porcelain boat, then place the porcelain boat in a tubular quartz tube, pass nitrogen protection into the tube furnace, and raise the temperature to 300°C with a heating rate of 5°C / min , the processing time is 2h. After the reaction was finished, the obtained black solid was ground into powder, and 2 g of the solid was dispersed in 10 mL of ethanol solution, and treated with an ultrasonic cleaner with a power of 200 w and a frequency of 40 kHz for 30 min to obtain a uniformly dispersed suspension. The turbid liquid was centrifuged at a centrifugal speed of 9000 rpm for 20 minutes to remove the black solid precipitate to obtain a clear liquid; the clear liquid was filtered with a 0.2 μm PES filter membrane to further remove insoluble impurities to obtain a filtrate. The main peak is measured by the fluorescence spectrometer at about 460nm, which is a typical blue fluorescence, and the ultraviolet absorpti...

Embodiment 3

[0043] 1 Preparation of carbon quantum dots

[0044] Take 5g of cleaned and dried pig small intestine and place it in a porcelain boat, then place the porcelain boat in a tubular quartz tube, pass nitrogen protection into the tube furnace, and raise the temperature to 350°C with a heating rate of 5°C / min , the processing time is 2h. After the reaction was finished, the obtained black solid was ground into a powder, 5 g of the solid was dispersed in 10 mL of DMF solution, and the power was 200 w, and the frequency was 40 kHz with an ultrasonic cleaner for 45 min to obtain a uniformly dispersed suspension. The solution was centrifuged at a centrifugal speed of 13,000 rpm for 10 minutes to remove the black solid precipitate to obtain a clear liquid; the clear liquid was filtered with a 0.45 μm nylon 66 filter membrane to further remove insoluble impurities to obtain a filtrate. The main peak is measured by the fluorescence spectrometer at about 440nm, which is a typical blue flu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com