Preparation method of high-stability boron nitride nanosheet-based fluorescent composite material

A composite material and high-stability technology, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of inorganic substrates that are rarely reported, and achieve the problems of solid-state fluorescence quenching and thermal quenching, strong fluorescence response, production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

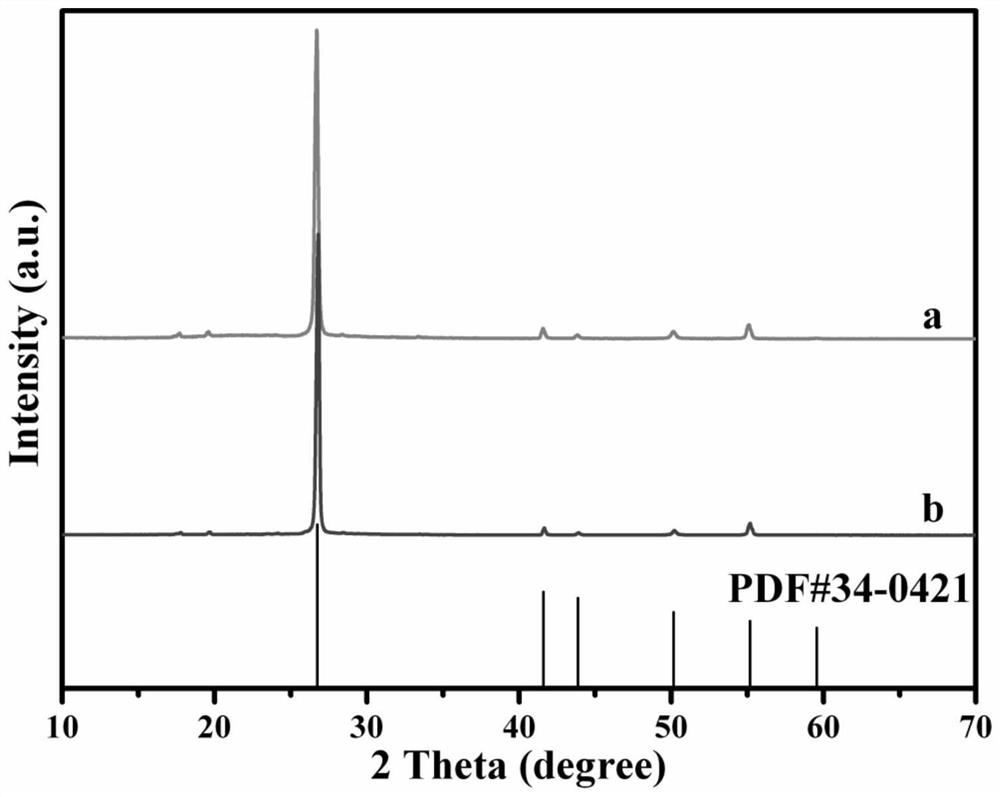

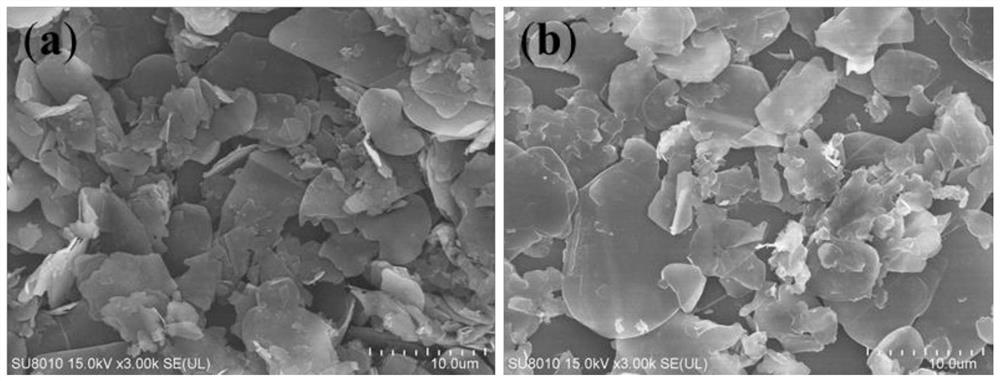

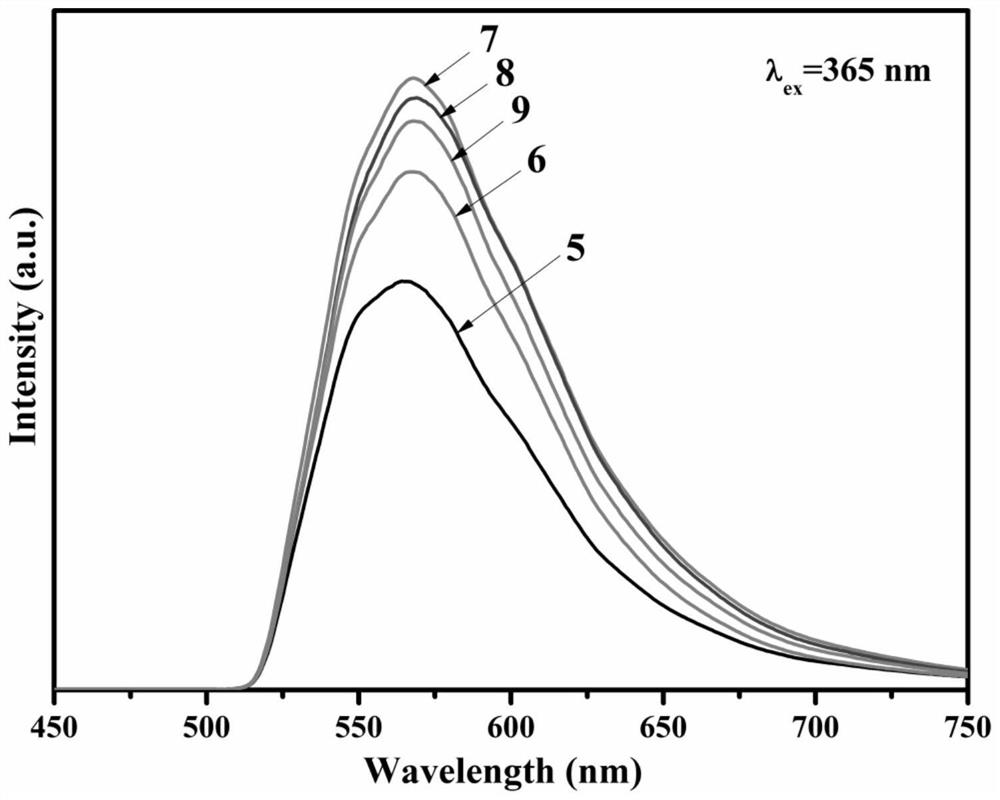

[0028] A preparation method of a highly stable boron nitride nanosheet-based fluorescent composite material is as follows:

[0029] (1) adding 1.0 g of boron nitride powder with a particle size of 2 to 20 μm into the mixed molten alkali composed of 2.16 g of potassium hydroxide and 2.84 g of sodium hydroxide and evenly ground to no graininess to obtain a mixture;

[0030] (2) Dissolving 0.08 g of nitrogen-doped carbon quantum dots with an emission wavelength of 570 nm in 1 mL of distilled water, adding it to the mixture obtained in step (1), and stirring into a paste-like mixture;

[0031] (3) put the paste mixture into a stainless steel autoclave lined with 25mL polytetrafluoroethylene, and react at 200°C for 2h;

[0032] (4) The product obtained after the reaction in step (3) was dispersed in 500 mL of distilled water, 220W ultrasonic peeling was performed for 1 h, and after the ultrasonication was completed, the obtained dispersion was centrifuged at 2000 rpm for 20 min, th...

Embodiment 2

[0037] A preparation method of a highly stable boron nitride nanosheet-based fluorescent composite material is as follows:

[0038] (1) adding 1.0 g of boron nitride powder with a particle size of 2 to 10 μm into the mixed molten alkali composed of 2.16 g of potassium hydroxide and 2.84 g of sodium hydroxide and evenly ground to no graininess to obtain a mixture;

[0039] (2) Dissolve 0.08g of nitrogen and sulfur-doped carbon quantum dots with an emission wavelength of 520nm in 1mL of distilled water, then add it to the mixture obtained in step (1), and stir to form a paste mixture;

[0040] (3) put the paste mixture into a 25mL PTFE-lined stainless steel autoclave, and react at 190°C for 2h;

[0041] (4) Disperse the product obtained after the reaction in step (3) in 500 mL of distilled water, 200W ultrasonic peeling for 2h, after the end of ultrasonication, centrifuge the obtained dispersion at 1500rpm for 30min, collect the supernatant and the lower sediment respectively, a...

Embodiment 3

[0046] A preparation method of a highly stable boron nitride nanosheet-based fluorescent composite material is as follows:

[0047] (1) 1.0g of boron nitride powder with a particle size of 2~20μm is added to the mixed molten alkali composed of 2.16g of potassium hydroxide and 2.84g of sodium hydroxide, and the powder is uniformly ground to no graininess to obtain a mixture;

[0048] (2) 0.08 g of boron-doped carbon quantum dots with an emission wavelength of 450 nm were dissolved in 1 mL of distilled water, then added to the mixture obtained in step (1), and stirred into a paste-like mixture;

[0049] (3) put the paste mixture into a stainless steel autoclave lined with 25mL polytetrafluoroethylene, and react at 180°C for 2h;

[0050] (4) Disperse the product obtained after the reaction in step (3) in 500 mL of distilled water, 180W ultrasonic peeling for 3 hours, after the end of ultrasonication, centrifuge the obtained dispersion at 1000 rpm for 40 min, collect the supernatant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com