Method for synthesizing water-soluble Nano CdllgTe stick, and usage of Nano stick

A synthesis method and nanorod technology, applied in the direction of nanotechnology, nanotechnology, nanostructure manufacturing, etc., can solve problems such as the undiscovered one-dimensional water-soluble CdHgTe nanorod preparation method, and achieve easy control of production conditions, low cost, and easy preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] a. According to the chemical reaction ratio, 0.2056 parts by weight of sodium borohydride and 0.195 parts by weight of tellurium powder are added to 5 parts by weight of ultrapure water, dissolved, and sodium tellurium hydride solution is prepared under the protection of argon;

[0022] b. In the L-mercaptoalanine solution containing 1 weight part of cadmium perchlorate and 0.2 weight part, add 0.6 weight part of thioglycolic acid under magnetic stirring to obtain the Cd-Cys-TGA solution;

[0023] c. Then adjust the Cd-Cys-TGA solution to pH=10 with aqueous sodium hydroxide solution, and fill with argon to remove dissolved oxygen in the Cd-Cys-TGA solution;

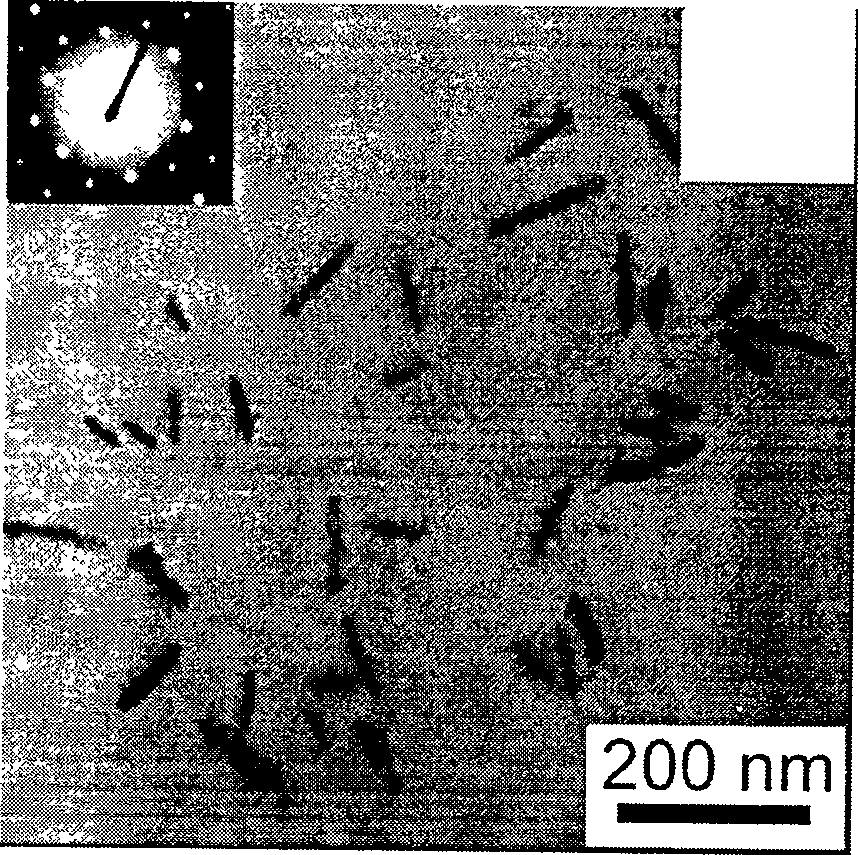

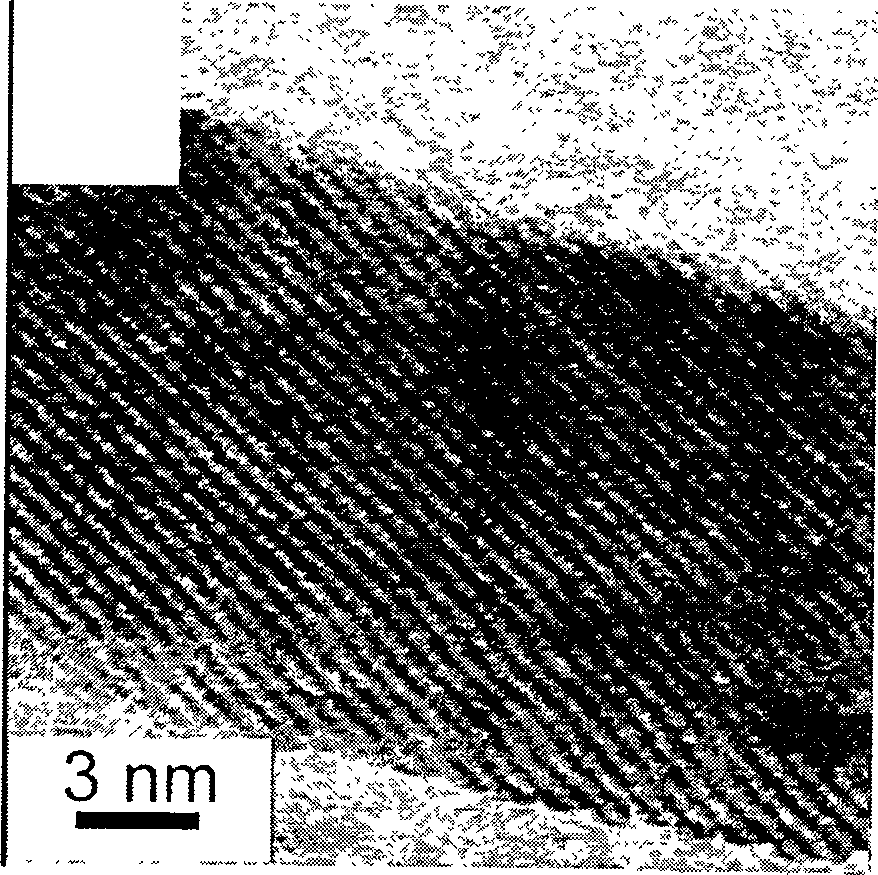

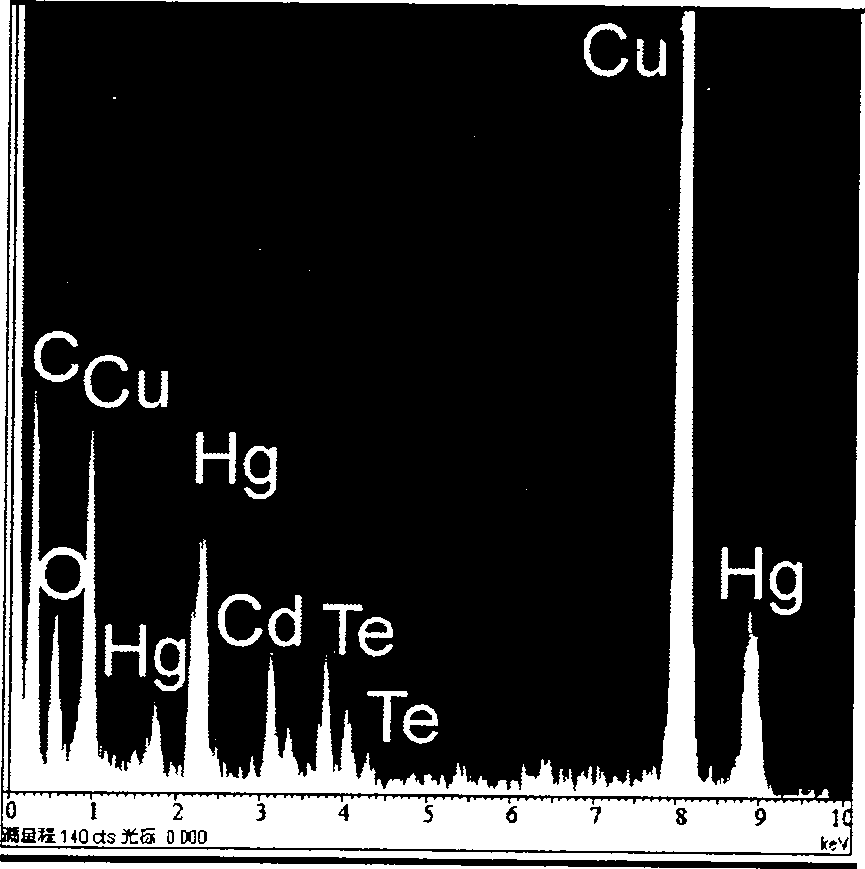

[0024] d. Mix the sodium hydride telluride solution in step a with the Cd-Cys-TGA solution prepared in step c according to the chemical reaction ratio, heat and reflux for 5 hours to obtain an aqueous solution of cadmium telluride nanorods, and the product is identified by X-ray powder diffraction as Cadmium tellur...

Embodiment 2

[0027] a. According to the chemical reaction ratio, 0.2056 parts by weight of sodium borohydride and 0.195 parts by weight of tellurium powder are added to 5 parts by weight of ultrapure water, dissolved, and sodium tellurium hydride solution is prepared under the protection of argon;

[0028] b. In the L-mercaptoalanine solution containing 1 weight part of cadmium perchlorate and 0.5 weight part, add 0.4 weight part of thioglycolic acid under magnetic stirring to obtain a Cd-Cys-TGA solution;

[0029] c. Then adjust the Cd-Cys-TGA solution to pH=11 with aqueous sodium hydroxide solution, and fill with argon to remove dissolved oxygen in the Cd-Cys-TGA solution;

[0030] d. According to the chemical reaction ratio, the sodium telluride hydride solution in step a is mixed with the Cd-Cys-TGA solution prepared in step c, heated and refluxed for 2 hours to obtain an aqueous solution of cadmium telluride nanorods, and the product is identified by X-ray powder diffraction as Cadmiu...

Embodiment 3

[0033] a. According to the chemical reaction ratio, 0.2056 parts by weight of sodium borohydride and 0.195 parts by weight of tellurium powder are added to 5 parts by weight of ultrapure water, dissolved, and sodium tellurium hydride solution is prepared under the protection of argon;

[0034] b. In the L-mercaptoalanine solution containing 1 weight part of cadmium perchlorate and 0.3 weight part, add 0.5 weight part of thioglycolic acid under magnetic stirring to obtain Cd-Cys-T6A solution;

[0035] c. Then adjust the Cd-Cys-TGA solution to pH=10.5 with aqueous sodium hydroxide solution, and fill with argon to remove dissolved oxygen in the Cd-Cys-TGA solution;

[0036] d. Mix the sodium hydride telluride solution in process a with the Cd-Cys-TGA solution prepared in process c according to the chemical reaction ratio, heat and reflux for 3 hours to obtain an aqueous solution of cadmium telluride nanorods, and the product is identified by X-ray powder diffraction as Cadmium te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com