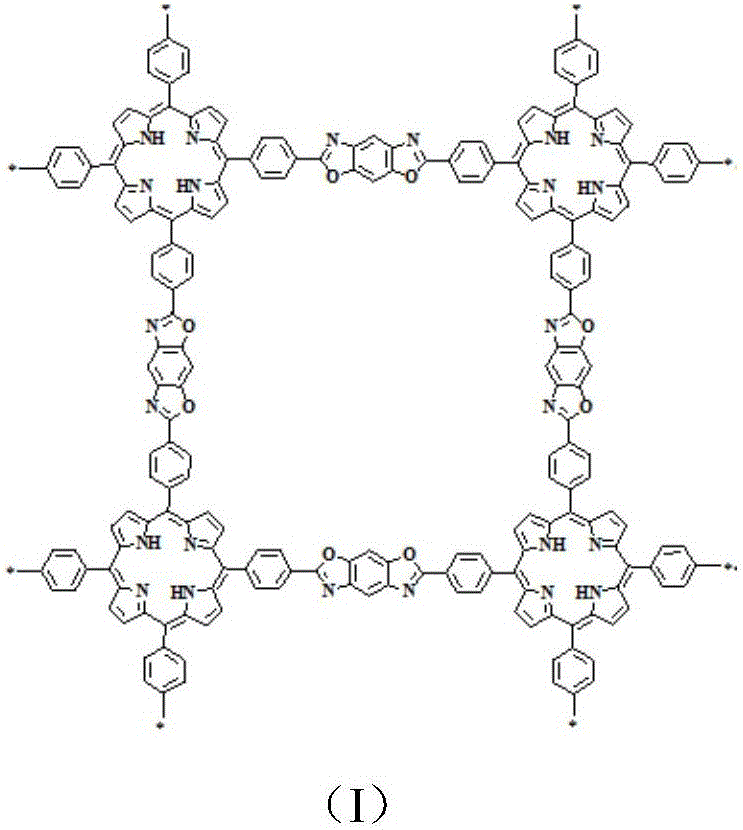

Porphyrin-structure-unit-containing porous network conjugated polymer and preparation method thereof

A technology of conjugated polymer and structural unit, applied in the field of porous network conjugated polymer and its preparation, can solve the problem of less porphyrin polymer, achieve excellent chemical stability and heat resistance, enhance macroscopic nonlinearity Coefficients and Effects of Nonlinear Optical Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

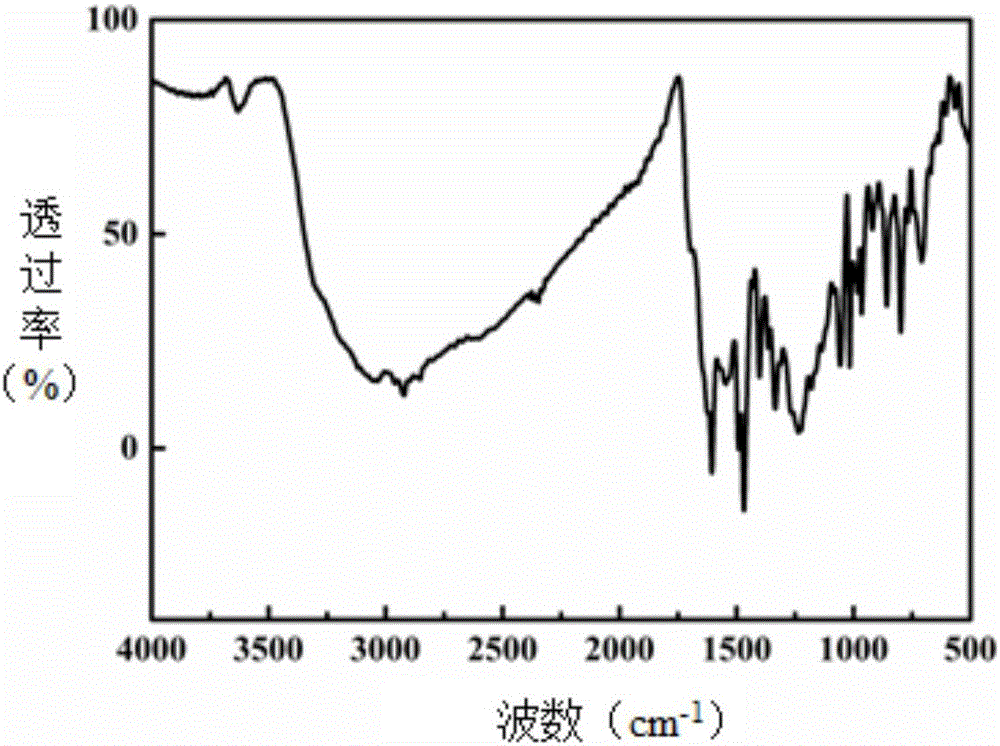

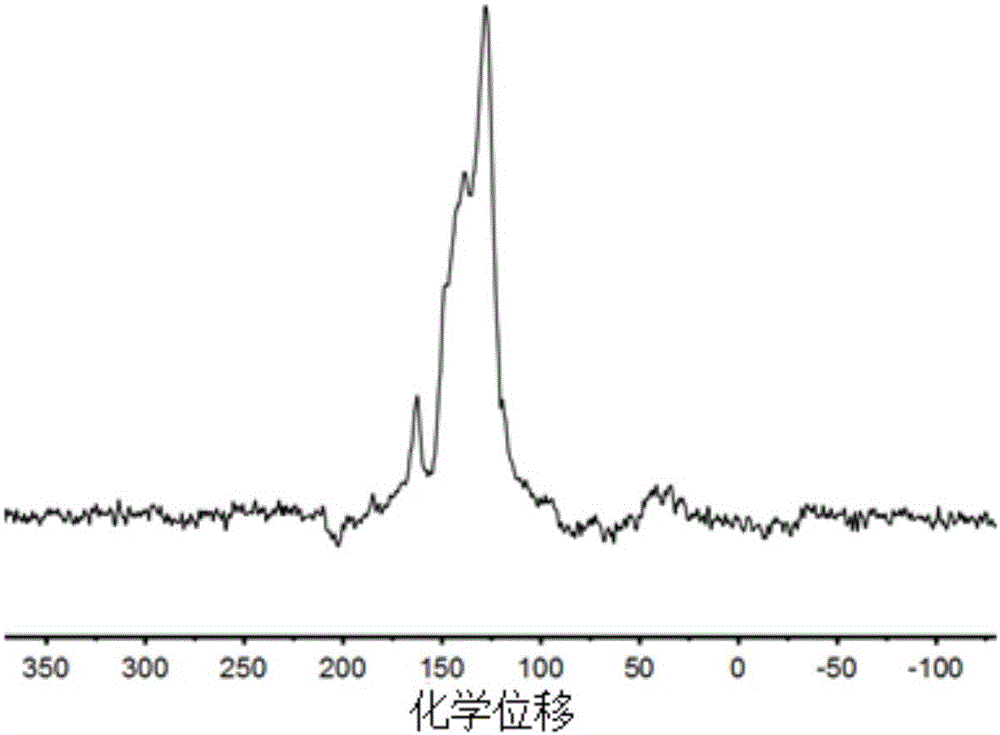

[0033] Under nitrogen protection conditions, in a 250mL four-necked flask, add 100mL concentration of 80% polyphosphoric acid, 1.71g 4,6-diaminoresorcinol hydrochloride, 0.001g SnCl 2 2H 2 O, heat and stir, heat slowly at a rate of 5°C / h, control the temperature at 40-100°C, remove hydrogen chloride gas, keep each temperature for 5 hours, after the hydrogen chloride gas is completely removed, weigh 3.48g TCPP and divide into 3 Put it into the reaction solution once, and gradually raise the temperature to 180°C at a rate of 10°C / h, and keep each temperature for 5 hours. After the reaction is over, the reaction device is lowered to room temperature, pour the polymer solution into a large beaker filled with deionized water, filter it with suction, and then wash it repeatedly with deionized water until the pH is 6, filter it with suction to obtain a solid at -40 ° C Freeze-dry under vacuum for 24 hours. Use a Soxhlet extractor to extract the dried solid, select methanol as the e...

Embodiment 2

[0036] Under the condition of nitrogen protection, in a 250mL four-neck flask, add 100mL concentration of 85% polyphosphoric acid, 1.71g 4,6-diaminoresorcinol hydrochloride, 0.001g SnCl 2 2H 2O, heat and stir, slowly heat at a rate of 10°C / h, control the temperature at 40-100°C, remove hydrogen chloride gas, keep each temperature for 12 hours, after the hydrogen chloride gas is completely removed, weigh 4.60g TCBP and divide into 5 Put it into the reaction solution once, and gradually raise the temperature to 180°C at a rate of 5°C / h, and keep each temperature for 2 hours. After the reaction is over, the reaction device is lowered to room temperature, pour the polymer solution into a large beaker filled with deionized water, filter it with suction, and then wash it repeatedly with deionized water until the pH is 7, filter it with suction to obtain a solid at -20°C , freeze-dried under vacuum for 12 hours. Use a Soxhlet extractor to extract the dried solid, select methanol as...

Embodiment 3

[0038] Under the condition of nitrogen protection, in a 250mL four-neck flask, add 100mL concentration of 85% polyphosphoric acid, 1.704g 4,6-diaminoresorcinol hydrochloride, 0.001g SnCl 2 2H 2 O, heat and stir, heat slowly at a rate of 10°C / h, control the temperature at 40-100°C, remove hydrogen chloride gas, keep each temperature for 5 hours, after the hydrogen chloride gas is completely removed, weigh 4.57g TCDBP in 3 Put it into the reaction solution once, and gradually raise the temperature to 180°C at a rate of 10°C / h, and keep each temperature for 8 hours. After the reaction is over, the reaction device is lowered to room temperature, pour the polymer solution into a large beaker filled with deionized water, filter it with suction, and then wash it repeatedly with deionized water until the pH is 7, filter it with suction to obtain a solid at -40 ° C Freeze-dry under vacuum for 24 hours. Use a Soxhlet extractor to extract the dried solid, select methanol as the extract...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com