A method for producing acidified oil by pressurizing soapstock or/and oil foot

A technology of acidifying oil and oil feet, which is applied in the direction of recovering fat oil/fatty acid from waste materials, producing fat, and recycling fatty substances. It can solve the problems of large sulfuric acid consumption, low reaction temperature, and high production cost, and achieve acid value and saponification The effect of increasing the price, increasing the reaction temperature, and improving the product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

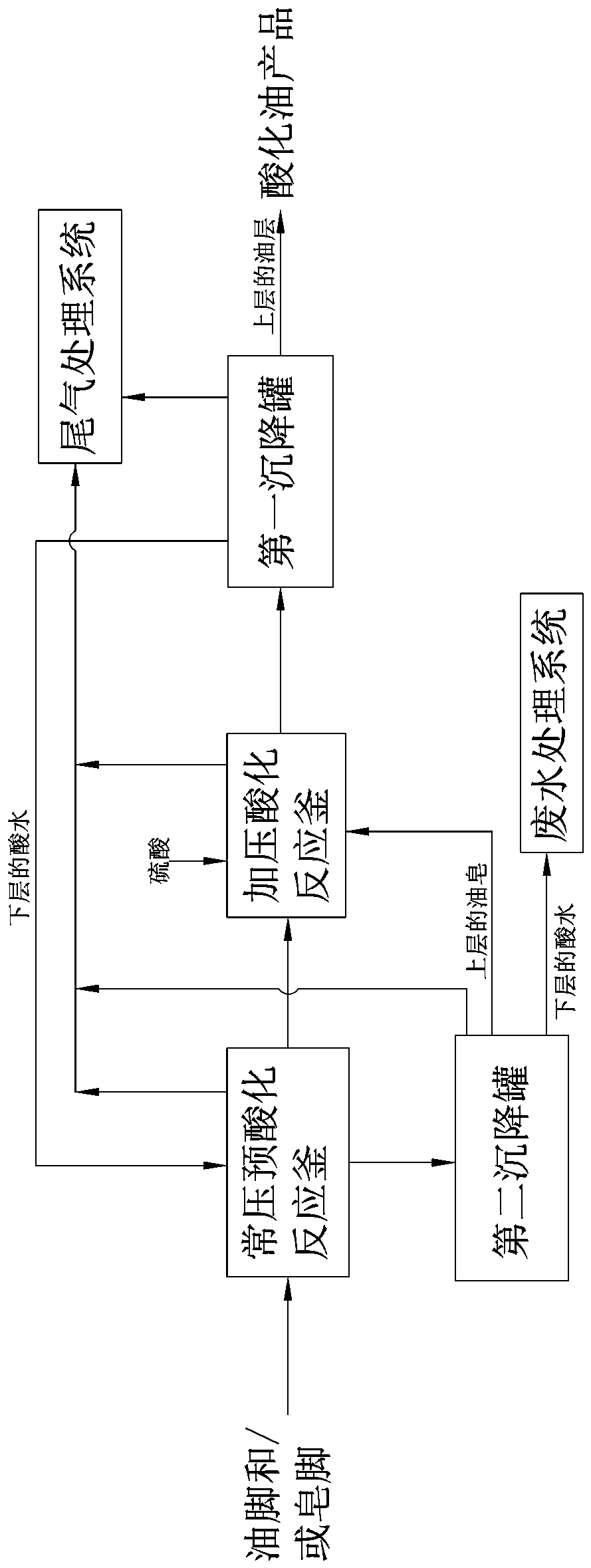

[0013] Such as figure 1 Shown, a kind of soapstock or / and oil foot pressurized reaction production acidified oil method, this method is: oil foot and / or soapstock and the sour water from the lower layer of the first settling tank are pumped into normal pressure pre-set The normal pressure pre-acidification reaction is carried out in the acidification reaction kettle, the mass ratio of the oil foot and / or soap stock to the acid water in the lower layer is 1:0.1-0.5; the reaction temperature of the normal pressure pre-acidification reaction is 30-90°C, and the Fully react by means of mechanical stirring or hydraulic circulation or pneumatic stirring;

[0014] After the normal pressure pre-acidification reaction is sufficient, it is discharged into the second settling tank for sedimentation and separation. The acid water in the lower layer in the second settling tank is pumped into the wastewater treatment system for corresponding treatment and then discharged up to the standard....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com