Heat treatment method for steel

A heat treatment method and steel technology, applied in the field of metallurgy, can solve problems such as reducing the quality of heat treatment products, and achieve the effects of good hot hardness and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

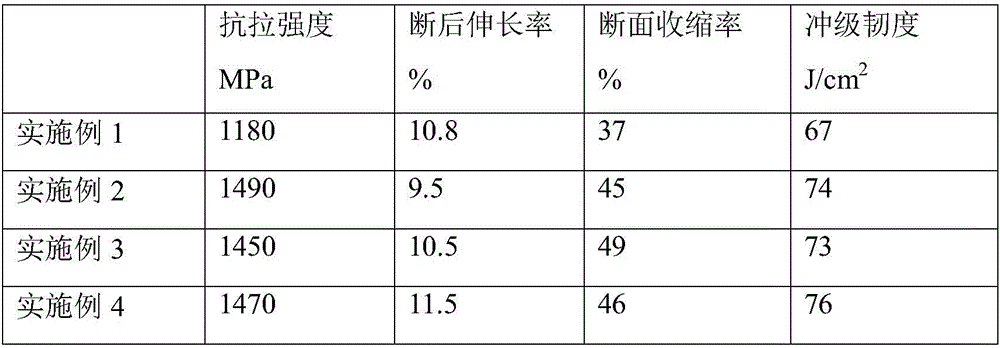

Examples

Embodiment 1

[0012] The steel is heated to 860°C for 1 hour, cooled to 720°C for 2 hours; then general annealing is performed, cooled to below 550°C and released from the furnace, and then the first preheating is to raise the temperature to 600°C and hold for 2 hours; the second preheating The heat was raised to 800°C and held for 2 hours. The temperature is raised to 1220°C for 0.5 hours, and then quenched. The quenching medium is a mixture of white oil, sodium nitrate, and sodium nitrite (the mass ratio of white oil: sodium nitrate: nitrous acid is 10:1:2), and immediately after quenching For tempering, the first tempering is 560°C for 1 hour; the second tempering is 550°C for 1.5 hours; the third tempering is 560°C for 1 hour.

Embodiment 2

[0014] Heating the steel to 860°C for 1 hour, cooling to 750°C for 2 hours; then performing general annealing, cooling to below 550°C, and then the first preheating is to raise the temperature to 650°C and hold for 2 hours; the second preheating The heat is raised to 850°C and maintained for 2 hours. The temperature is raised to 1220°C for 0.5 hours, and then quenched. The quenching medium is a mixture of white oil, sodium nitrate, and sodium nitrite (the mass ratio of white oil: sodium nitrate: nitrous acid is 10:1:2), and immediately after quenching For tempering, the first tempering is 560°C for 1 hour; the second tempering is 550°C for 1.5 hours; the third tempering is 560°C for 1 hour.

Embodiment 3

[0016] Heating the steel to 880°C for 2 hours, cooling to 720°C for 2 hours; then performing general annealing, cooling to below 550°C, and then the first preheating is to raise the temperature to 600°C and hold for 2 hours; the second preheating The heat was raised to 800°C and held for 2 hours. The temperature is raised to 1280°C for 1 hour, and then quenched. The quenching medium is a mixture of white oil, sodium nitrate, and sodium nitrite (the mass ratio of white oil: sodium nitrate: nitrous acid is 10:1:2). Immediately after quenching For tempering, the first tempering is 560°C for 1 hour; the second tempering is 550°C for 1.5 hours; the third tempering is 560°C for 1 hour.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com