Water pump for sewerage system

A sewage system and water pump technology, which is applied to the components of the pumping device for elastic fluids, pumps and pumps for special fluids, etc., can solve the problems of reducing sewage efficiency, consuming a lot of manpower, material resources and time, and motor overload, etc. To achieve the effect of reducing working performance and service life, improving filtering effect and reducing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

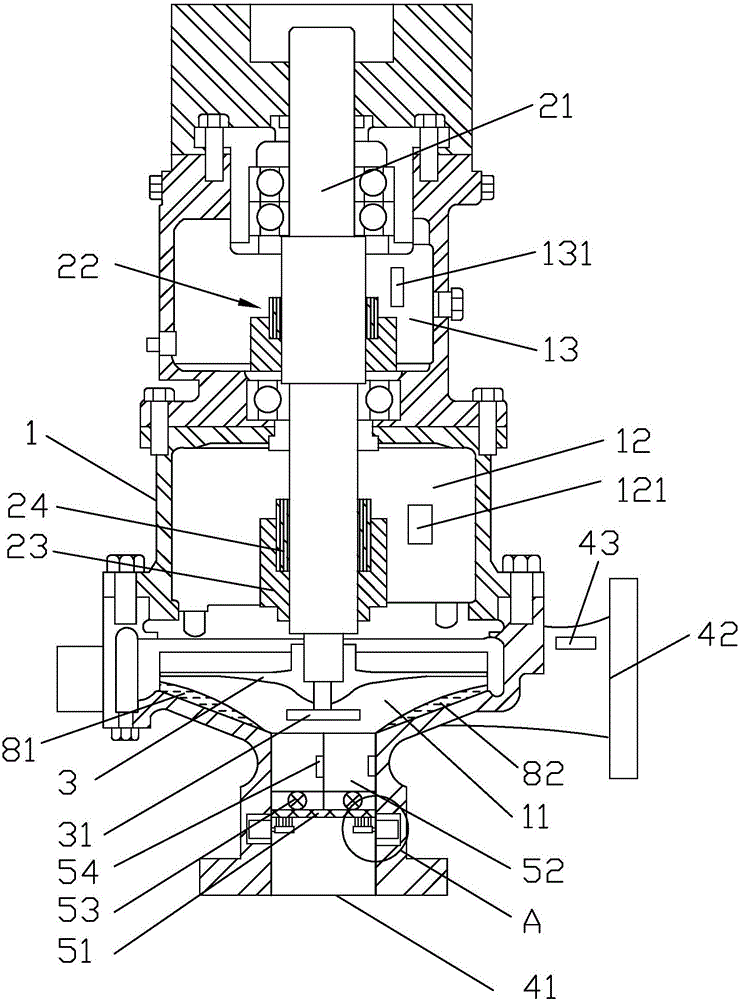

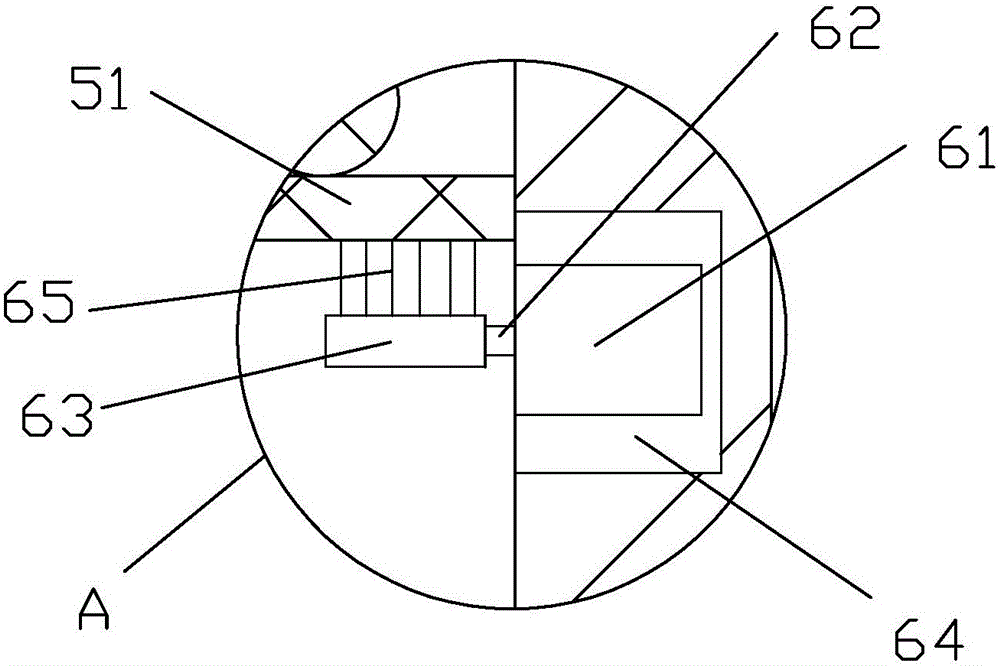

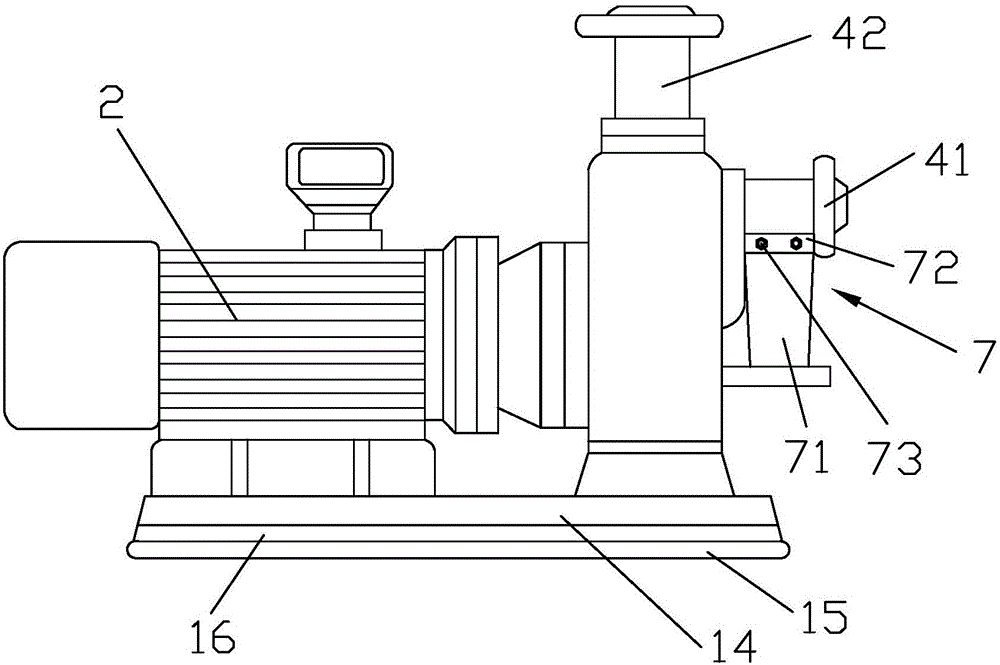

[0027] Such as Figure 1-5 As shown, it is a water pump for sewage system of the present invention, including pump body 1, motor 2, impeller 3, water inlet 41 and water outlet 42, motor 2 includes stator, rotor and rotating shaft 21, rotating shaft 21 and impeller 3 Fixedly connected, the pump body 1 includes a sewage discharge chamber 11, a driving chamber 12 and an oil filling chamber 13, the sewage discharge chamber 11, the driving chamber 12 and the oil filling chamber 13 are isolated from each other, and the water inlet 41 and the water outlet 42 communicate with the sewage discharge chamber 11 respectively. The isolated sewage chamber 11, driving chamber 12 and oiling chamber 13 prevent water from entering the driving chamber 12 and oiling chamber 13 from the sewage chamber 11, so that the parts in the driving chamber 12 and the oiling chamber 13 are polluted and damaged, and the water pump is reduced. service life and increase maintenance costs. A sealing device 22 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com