Method for processing steel bottles of high-purity arsine

A pure arsine and steel cylinder technology, applied in the method of container discharge, gas treatment/storage purpose, fluid treatment, etc., can solve the problems of small output, no high-purity arsine steel cylinder treatment system, etc., and achieve the effect of reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

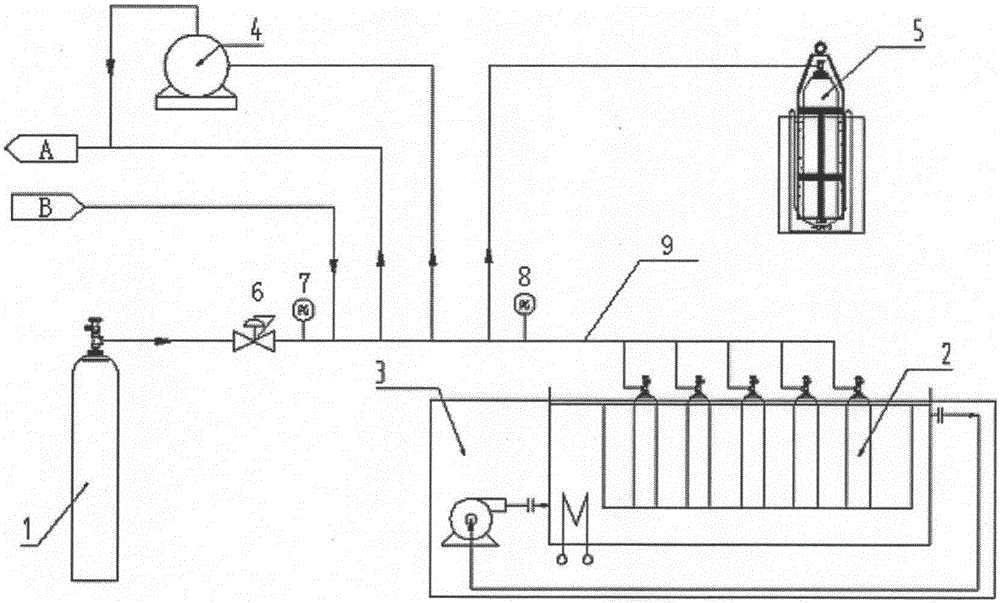

[0022] A steel cylinder method for processing high-purity arsine:

[0023] Step 1: Use high-purity helium A to replace the entire main pipeline 9 to ensure that the pipeline is not polluted, and then use the vacuum pump 4 to vacuum the main pipeline 9;

[0024] Step 2: Set the temperature of the oven 3 at 60°C. Under the condition of keeping the vacuum pump 4 running, vacuum bake the steel cylinder 2 to be treated for 8 hours, and keep the steel cylinder 2 at 60-100°C; The steel cylinder 2 is filled with helium until the pressure gauge 7 shows 1 bar, and then the helium is pumped out by the vacuum pump 5 until the vacuum gauge 8 shows 0;

[0025] Step 3: Open the cylinder valve of the source gas cylinder 1, set the pressure of the pressure regulating valve 6 at 1 bar, fill the cylinder 2 to be treated with arsine gas until the pressure gauge 7 shows 0.1 bar, and carry out arsenic passivation on the cylinder 2 to be treated. Bake for 24 hours;

[0026] Step 4: Open the cylind...

Embodiment 2

[0030] A steel cylinder method for processing high-purity arsine:

[0031] Step 1: Use high-purity helium A to replace the entire main pipeline 9 to ensure that the pipeline is not polluted, and then use the vacuum pump 4 to vacuum the main pipeline 9;

[0032] Step 2: Set the temperature of the oven 3 at 100°C. Under the condition of keeping the vacuum pump 4 running, vacuum bake the steel cylinder 2 to be treated for 4 hours, and keep the steel cylinder 2 at 60-100°C; The steel cylinder 2 is filled with helium until the pressure gauge 7 shows 1.5 bar, and then the helium is pumped out by the vacuum pump 4 until the vacuum gauge 8 shows 0;

[0033] Step 3: Open the cylinder valve of the source gas cylinder 1, set the pressure of the pressure regulating valve 6 at 3bar, fill the cylinder 2 to be treated with arsine gas until the pressure gauge 7 shows 0.5bar, and carry out arsenic passivation on the cylinder 2 to be treated. Bake for 12 hours;

[0034] Step 4: Open the cylin...

Embodiment 3

[0038] A steel cylinder method for processing high-purity arsine:

[0039] Step 1: Use high-purity helium A to replace the entire main pipeline 9 to ensure that the pipeline is not polluted, and then use the vacuum pump 4 to vacuum the main pipeline 9;

[0040] Step 2: Set the temperature of the oven 3 at 80°C. Under the condition of keeping the vacuum pump 4 running, after the steel cylinder 2 to be treated is vacuum baked for 6 hours, the steel cylinder 2 to be treated is always kept at 60-100°C; The steel cylinder 2 is filled with helium until the pressure gauge 7 shows 1.3 bar, and then the helium is pumped out by the vacuum pump 4 until the vacuum gauge 8 shows 0;

[0041] Step 3: Open the cylinder valve of the source gas cylinder 1, set the pressure of the pressure regulating valve 6 at 2bar, fill the cylinder 2 to be treated with arsine gas until the pressure gauge 7 shows 0.3bar, and carry out arsenic passivation on the cylinder 2 to be treated. Bake for 18 hours;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com