Large power LED structure adopting COB packaging

An LED structure, high-power technology, applied in electrical components, electrical solid devices, circuits, etc., can solve problems such as poor heat transfer, low thermal conductivity of insulating layers, etc., to improve heat dissipation performance, reduce chip junction temperature, and improve heat dissipation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

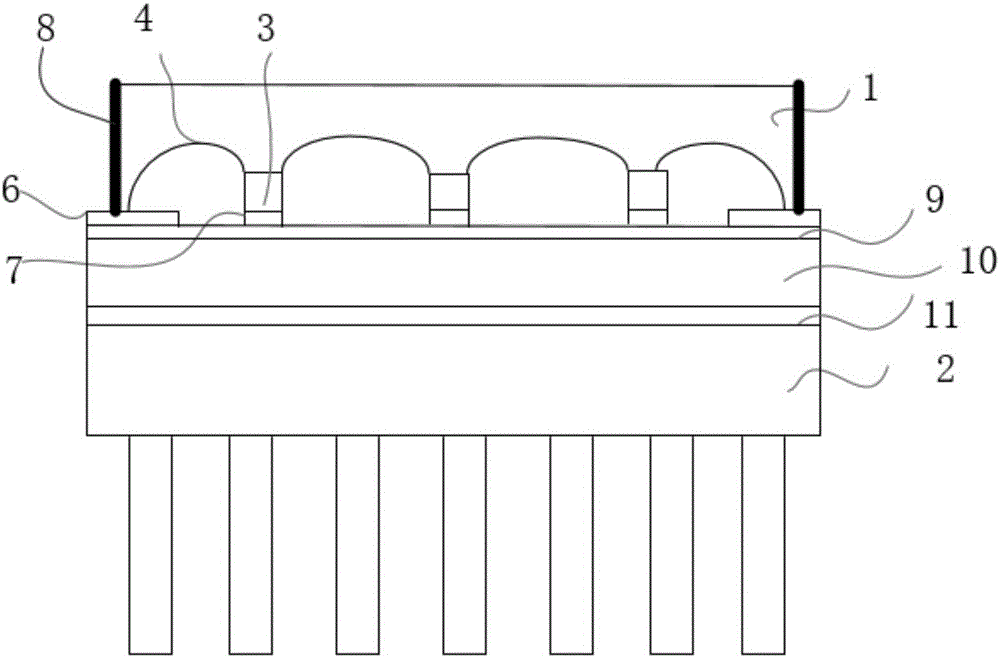

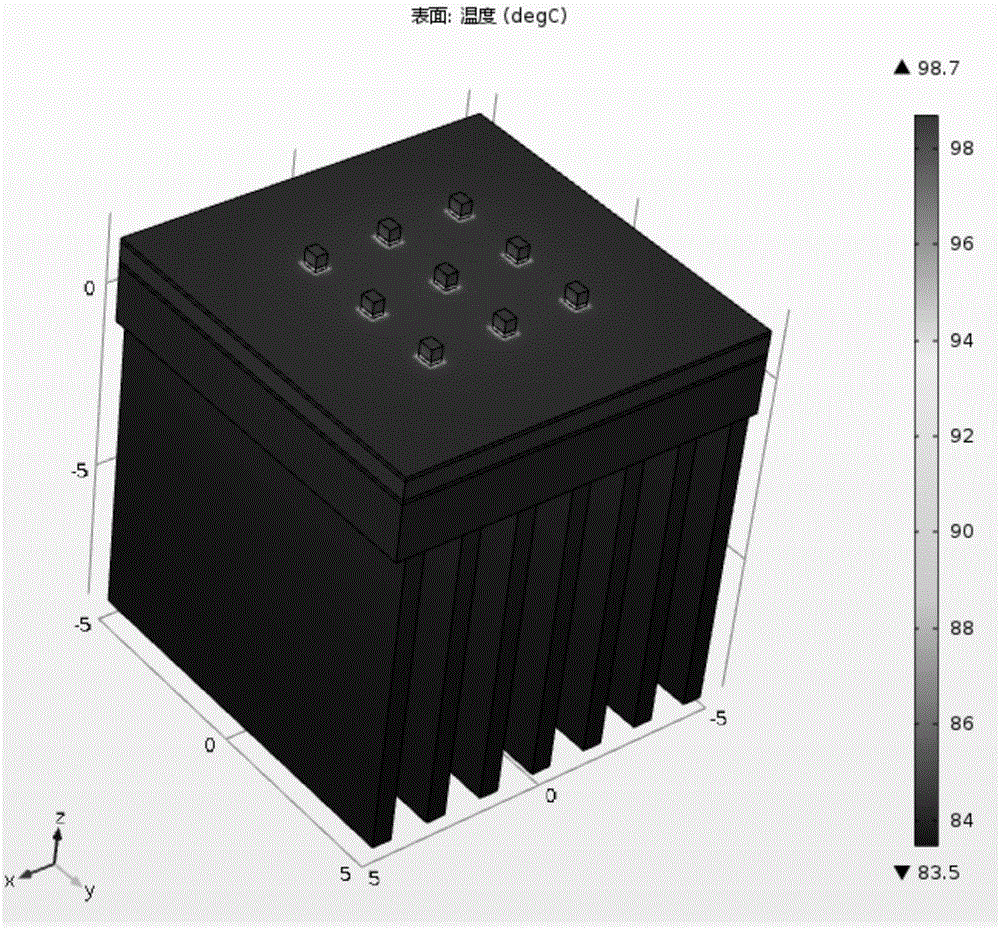

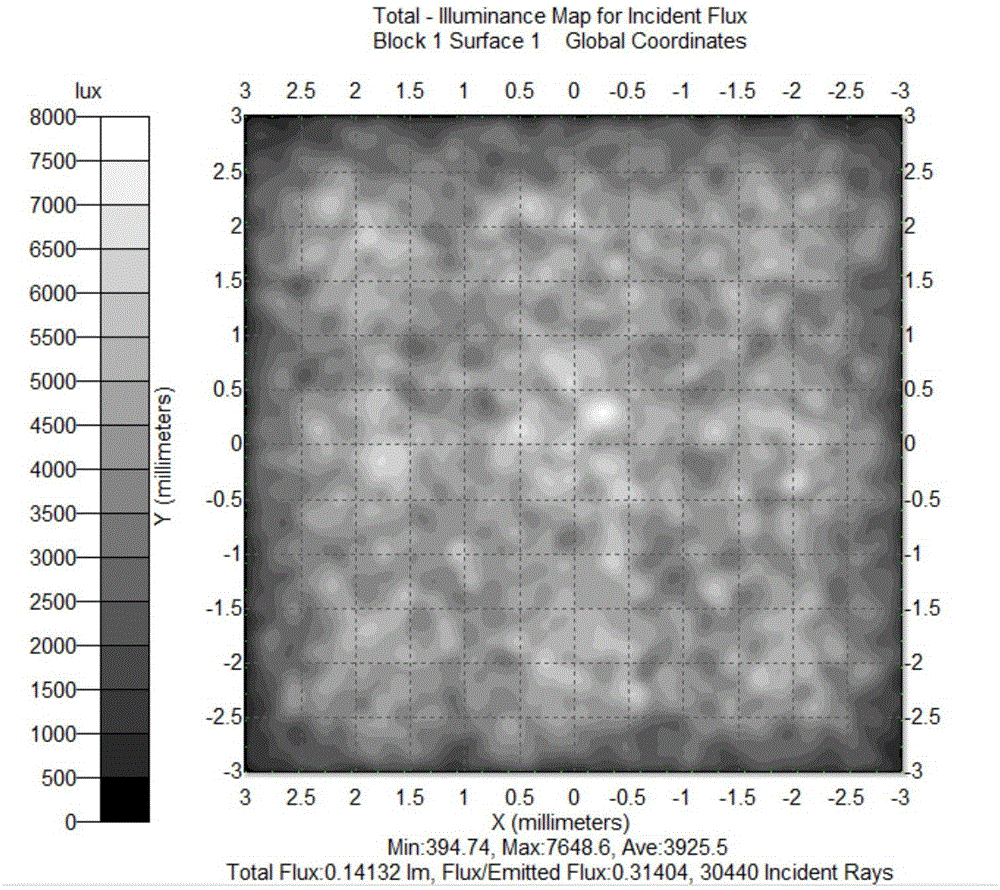

[0040]A high-power LED structure adopting COB packaging, including a radiator 2, an LED chip structure 3 and an encapsulation layer 1 located on the radiator; the encapsulation layer 1 is a mixture of epoxy resin and phosphor powder; the heat dissipation The radiator 2 is a ceramic radiator, the size of the radiator is 10mm*10mm*1.5mm, the spacing of the fins of the radiator will affect the convection with the air, the thickness of the fins will affect the contact area with the air, and then affect the performance of the radiator and chip junction temperature, this embodiment is optimized in many ways to set the thickness of the radiator fins to 0.5mm, the height to 8mm, and the spacing to 1mm; the spacing of the LED chips will affect the temperature gradient on the surface of the radiator and the junction temperature of each chip The distribution will also affect the maximum value and average value of the illuminance. In this embodiment, after multiple optimizations, the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com