Method for forming multilayer film

A multi-layer coating film and coating film technology, applied in chemical instruments and methods, devices for coating liquid on surfaces, coatings, etc., can solve the problems of increased number of coating processes, complicated operations, and increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0225]

[0226] In a reaction vessel for producing a common acrylic resin emulsion equipped with a stirrer, a thermometer, a dropping funnel, a reflux cooler, and a nitrogen introduction pipe, 445 parts of water and NEWCOL 293 (an emulsifier manufactured by Japan Emulsifier Co., Ltd., trade name ) 5 parts, while stirring, the temperature was raised to 75°C. Using a homogenizer, the monomer mixture (methyl methacrylate 7.8%, butyl acrylate 54.2%, styrene 10.0%, 4-hydroxybutyl acrylate 20.6%, methacrylic acid 1.6%, ethyl acrylate 6.0%), A mixture of 240 parts of water and 30 parts of NEWCOL 293 was emulsified, and this monomer pre-emulsion was dropped into the above-mentioned reaction container over 3 hours while stirring. In parallel with the dropping of the monomer pre-emulsion, an aqueous solution obtained by dissolving 1 part of APS (ammonium persulfate) as a polymerization initiator in 50 parts of water was evenly added dropwise to the above-mentioned reaction vessel unti...

manufacture example 2

[0227]

[0228] Aqueous sodium hydroxide solution was added to a reaction vessel containing 128.2 g (4.0 moles) of methanol and 74.1 g (1.0 moles) of n-butanol, and after adjusting the pH to 11.8, paraformaldehyde (92% CH 2 O) 169.7 g (5.2 mol). After heating at 60° C. for 20 minutes and dissolving paraformaldehyde in methanol, 126.1 g (1.0 mol) of melamine was added, and pH was adjusted to 13.0 with an aqueous sodium hydroxide solution. The reaction was carried out for 1 hour while distilling methanol out of the system at reflux temperature, and then concentrated under normal pressure until the internal temperature became 110°C. Next, 320.4 g (10.0 mol) of methanol and 741.2 g (10.0 mol) of n-butanol were added, and the pH was adjusted to 2.0 with sulfuric acid, followed by reaction at 30° C. for 3.5 hours. Then, the pH was adjusted to 9.2 with aqueous sodium hydroxide solution. The neutralized salt was filtered out, and the filtrate was concentrated under reduced pressur...

manufacture example 3

[0229]

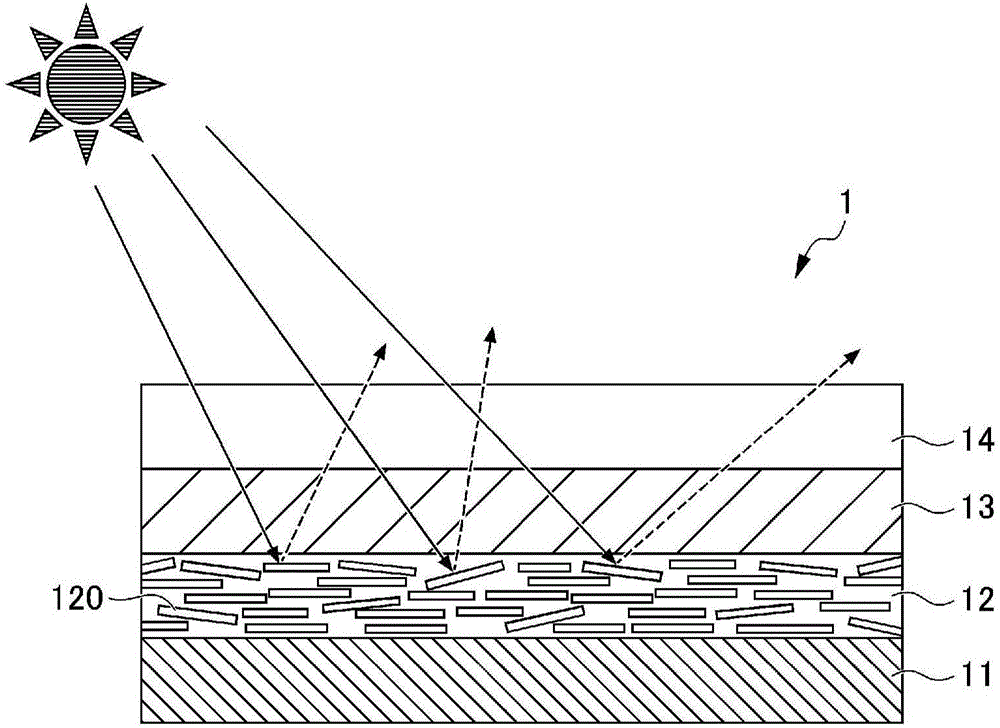

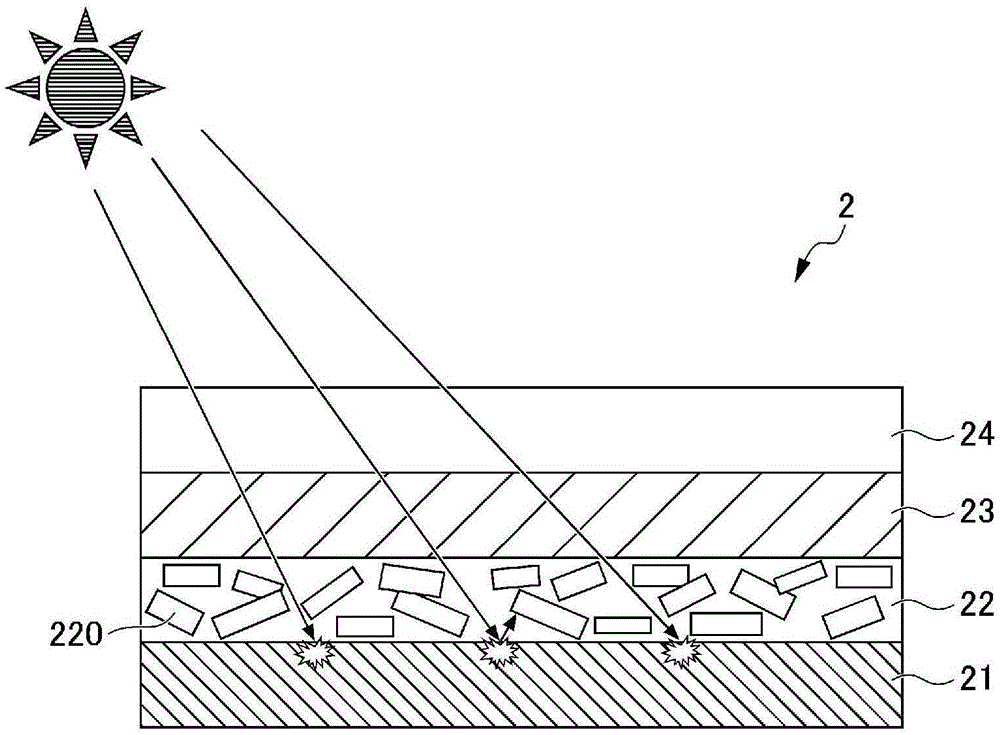

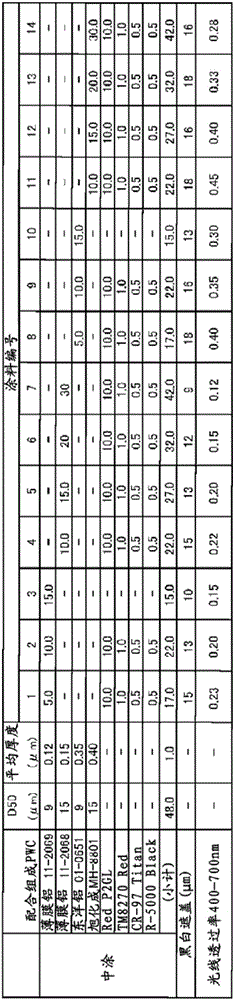

[0230] The hydroxyl-containing acrylic resin emulsion of Production Example 1, the melamine resin of Production Example 2, and the bright pigments shown in Table 1 (film aluminum 11-2069, film aluminum 11-2068, aluminum bright pigment Alpaste manufactured by Toyo Aluminum Co., Ltd. 01-0651, bright pigment MH-8801 manufactured by Asahi Kasei) and coloring pigments (RedP2GL, TM8270Red, CR-97Titan, R-5000Black) were formulated according to the contents shown in Table 1. Then, the intermediate coating materials of paint numbers 1 to 14 shown in Table 1 were obtained by uniform dispersion. In addition, "thin film aluminum 11-2069" in Table 1 is "Alumi Paste 11-2069" manufactured by Toyo Aluminum Co., Ltd., "thin film aluminum 11-2068" is "Alumi Paste 11-2068" manufactured by Toyo Aluminum Co., Ltd., "Toyo Aluminum 01-0651" is "Alumi Paste 01-0651" manufactured by Toyo Aluminum Corporation, "Asahi Kasei MH-8801" is "Alumi Paste MH-8801" manufactured by Asahi Kasei Corpora...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com