Energy-saving and environment-friendly carbon disulfide gasification reactor

A technology of carbon disulfide, energy saving and environmental protection, which is applied in the direction of carbon disulfide, carbon sulfur compounds, chemical industry, etc., can solve the problems of high consumption of refractory materials for building furnaces, large occupied area, and affected production, so as to reduce the occupied area of the furnace body and reduce the Furnace construction cost and the effect of saving furnace construction materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

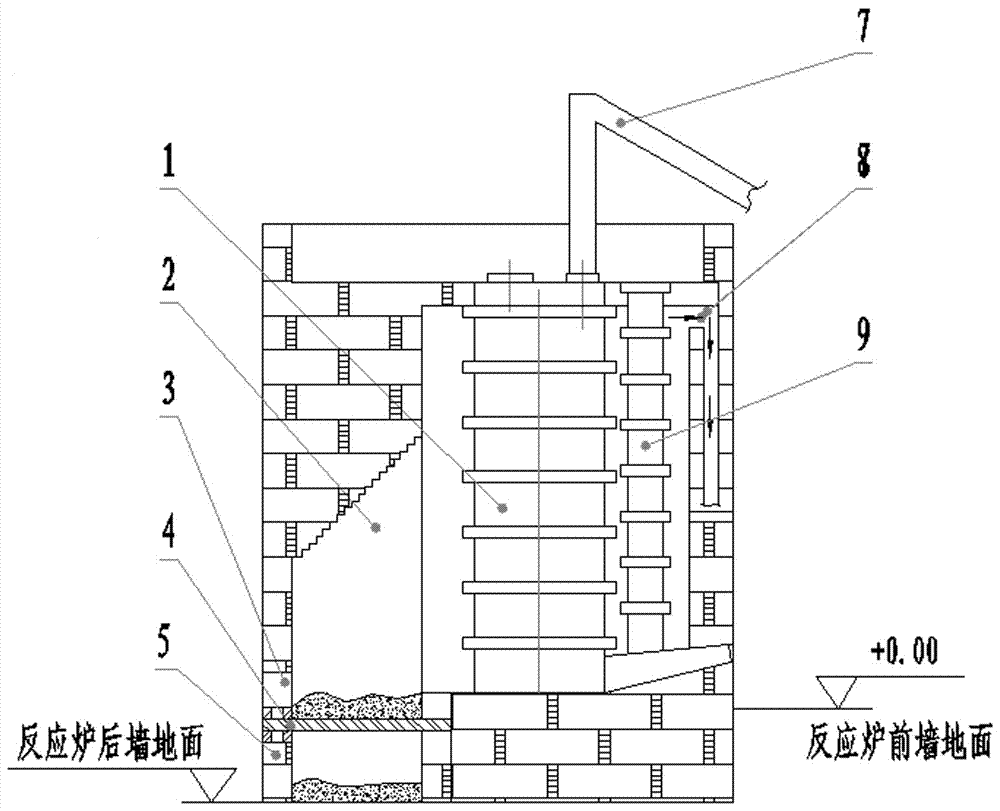

[0030] Such as figure 2 The shown energy-saving and environment-friendly carbon disulfide gasification reaction furnace includes gasification reaction furnace body 1, external heating furnace 2, flue gas discharge channel 6 in the corner of the rear wall of the gasification reaction furnace, carbon disulfide recovery pipe, 7, and front of the gasification reaction furnace The flue gas discharge channel 8 in the corner of the wall, the small sulfur gasification furnace 9, the external heating furnace 2 includes a fuel inlet 3, a furnace bar 4, and a slag removal port 5, and the carbon disulfide recovery pipeline 7 is arranged in the gasification reaction furnace body 1. The top is fixedly connected with the gasification reactor. The gasification reaction furnace body 1, the external heating furnace 2, the flue gas discharge channel 6 at the corner of the rear wall of the gasification reaction furnace, the flue gas discharge channel 8 at the corner of the front wall of the gasi...

Embodiment 2

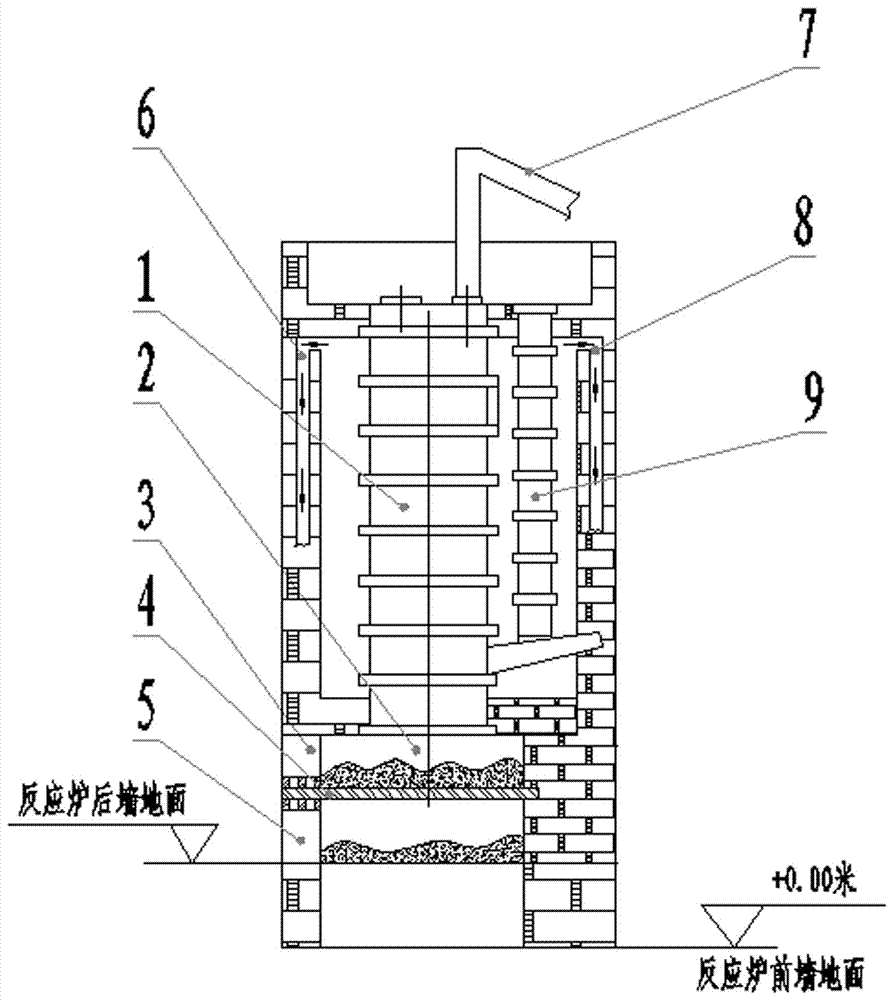

[0032] Such as image 3 The shown energy-saving and environment-friendly carbon disulfide gasification reaction furnace includes a gasification reaction furnace body 1, an external heating furnace 2, a flue gas discharge channel 6 at the corner of the back wall of the gasification reaction furnace, a carbon disulfide recovery pipe 7, and a front wall of the gasification reaction furnace The flue gas discharge channel 8 in the upper corner, the small sulfur gasification furnace 9, and the carbon disulfide recovery pipeline 7 are arranged on the top of the gasification reaction furnace body 1 and are fixedly connected with the gasification reaction furnace. The furnace chamber of the external heating furnace 2 is equipped with mechanical automatic fuel addition and automatic slag discharge facilities, including an automatic fuel addition device 10, an automatic rotary grate device 11, an automatic slag unloading device 12, and an automatic rotary grate device 11 horizontally arra...

Embodiment 3

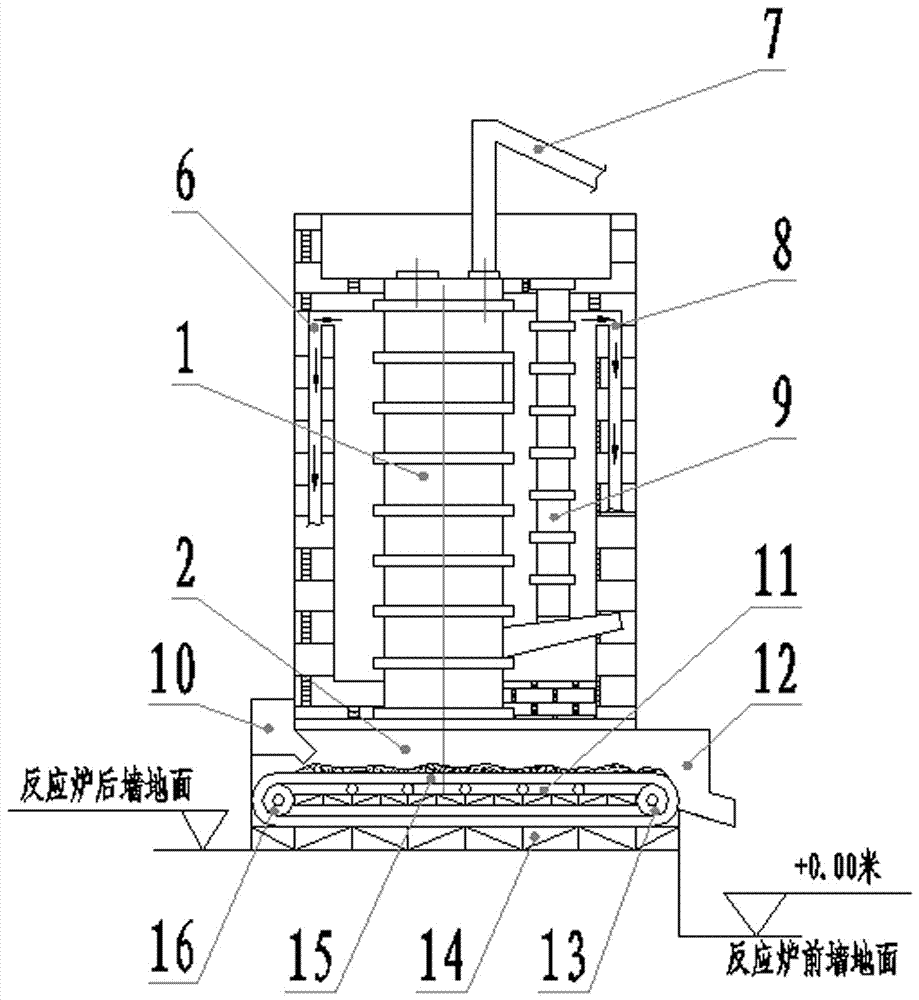

[0034] Such as Figure 4The shown energy-saving and environment-friendly carbon disulfide gasification reaction furnace includes a gasification reaction furnace body 1, an external heating furnace 2, a flue gas discharge channel 6 at the corner of the back wall of the gasification reaction furnace, a carbon disulfide recovery pipe 7, and a front wall of the gasification reaction furnace The flue gas discharge channel 8 in the upper corner, the small sulfur gasification furnace 9, and the carbon disulfide recovery pipeline 7 are arranged on the top of the gasification reaction furnace body 1 and are fixedly connected with the gasification reaction furnace. The gas pipeline 17, the gas control valve 18, and the coal injection nozzle 19 are evenly arranged at the bottom of the furnace cavity of the external heating furnace 2. The gas control valve 18 is arranged on the gas pipeline 17 outside the rear wall at the bottom of the heating furnace cavity. The pipeline 17 is fixedly co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com