Comprehensive utilization method for chlorination-process titanium dioxide post-treatment wastewater

A titanium dioxide, chlorination technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem of slow natural evaporation rate, large energy consumption, waste water overflowing into sedimentation tanks, etc. problem, to achieve the effect of fast processing rate, avoiding pollution and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

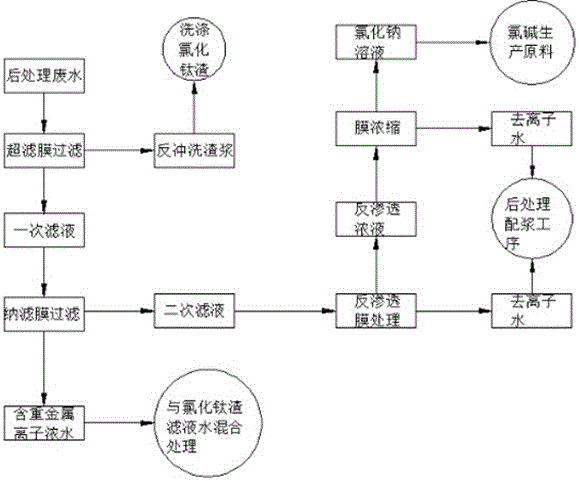

Image

Examples

Embodiment

[0026] The following is the experimental data obtained by using the present invention to treat the wastewater after the treatment of the chlorination titanium dioxide in the laboratory.

[0027] 1. Collect 1000ml of post-treatment wastewater and pass it into the ultrafiltration membrane equipment. Under the push of pressure, the water, inorganic ions, metal ions, etc. in the post-treatment wastewater pass through the ultrafiltration membrane, while fine particles such as titanium dioxide are retained; after filtration The primary filtrate and backwash slurry containing heavy metal ions are obtained, the backwash slurry can be used for washing the titanium chloride slag produced in the chlorination section, and the SS content of the primary filtrate is 28ppm;

[0028] 2. Pass the obtained primary filtrate into the nanofiltration equipment. Since the nanofiltration membrane can effectively intercept divalent and above-divalent metal ions, it can effectively intercept the divalent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com