Coking wastewater advanced treatment method and system

A coking wastewater and advanced treatment technology, which is applied in multi-stage water treatment, water/sewage treatment, natural water treatment, etc., can solve the problem that the coking wastewater treatment process cannot meet the discharge requirements, and achieve stable and efficient treatment effects, pharmaceutical use The effect of small amount and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

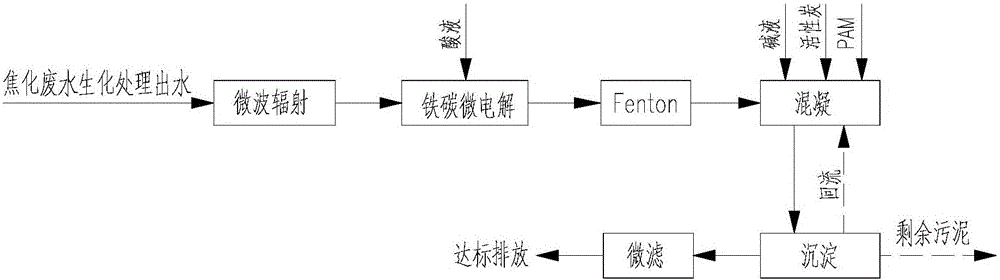

Image

Examples

Embodiment 1

[0033] The coking wastewater advanced treatment system in this embodiment includes pH value detection equipment, pH value adjustment equipment, microwave treatment equipment, iron-carbon micro-electrolytic catalytic reduction treatment equipment, heterogeneous Fenton catalytic oxidation treatment equipment, mixed Coagulation treatment equipment, microfiltration treatment device, aeration device; wherein, the heterogeneous Fenton catalytic oxidation treatment equipment includes FeSO 4 Solution dosing device and H 2 o 2 A solution dosing device, the coagulation treatment equipment includes a coagulation tank, a sedimentation tank, an activated carbon dosing device and a coagulant aid dosing device.

[0034] The pH value detection equipment and the pH value adjustment equipment are used to detect and adjust the pH value of the coking wastewater;

[0035] The microwave treatment equipment is used for microwave radiation treatment of coking wastewater after biochemical treatment;...

Embodiment 2

[0042] The coking wastewater advanced treatment method in this embodiment is realized by the coking wastewater advanced treatment system in Example 1.

[0043] The specific process of the coking wastewater advanced treatment method in this embodiment is as follows: the coking wastewater after biochemical treatment is first subjected to microwave treatment by microwave radiation equipment to heat and polarize organic pollutant molecules. The optimal power range of microwave is 200-600w , The optimal microwave reaction time is 3-10min. Then use PH value detection equipment and PH value adjustment equipment to use 1+3 sulfuric acid solution to adjust the pH value of the microwave-treated effluent to 3-5, and use iron-carbon micro-electrolytic catalytic reduction treatment equipment to carry out iron-carbon micro-electrolytic catalytic reduction treatment of coking wastewater for iron-carbon micro-electrolytic catalytic reduction treatment. For carbon micro-electrolysis catalytic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com